AUSTIN SEVEN ENGINE REBUILD

Article kindly

reproduced from the Herefordshire A7 Club.

Part 3 - Crankshaft & con rods

Part 1 – The crankcase,

camshaft, oil pump, rear main housing.

Part 2 - The

cylinder block and connecting rods

Part 4 -

Main Bearings

Part 5 -

Carburettors, manifolds, clutch and fan spindle

Part 6 - Flywheel

Part 7 -

Reassembly

Part 8 -

Attaching the block and cylinder head

Crankshaft

If you drive your A7 like a nervous granny, or the

engine is to be used simply as a spare, then I believe it is perfectly feasible

to retain an original Austin crankshaft, so-long as it has been carefully crack

tested and found to be sound. A common area to find cracks on two-bearing

crankshafts is the rear web just behind number four big-end journal but they can

also crack on the journals and elsewhere. However, if you are inclined to belt

along and rev the engine enthusiastically in the gears and/or seek an especially

high level of reliability from your bottom end, then a modern replacement

crankshaft is probably a good idea. This is simply because ‘two-bearing’

crankshafts tend to flex when revved hard (i.e. go round like a skipping rope)

and this can (and probably ‘will’) eventually lead to a broken crank’ through

‘fatigue’ failure. Many original Austin cranks have been whizzing around for

eighty or ninety years now, so it is mind boggling to think how many times they

may have already flexed. You might be lucky enough to have a sound Austin crank

that doesn’t need regrinding together with four beautifully matching conrods and

I can understand the temptation to re-utilise these items. However, if the

big-end journals (sometimes referred-to as crank pins) need regrinding and

consequently the conrods need re-metalling, then this significant cost might be

better spent as a contribution towards a modern crank.

The only modern crankshafts of which I have personal

experience, are the 15/16” splash-feed ones made by Phoenix Engineering and I

have found them to be perfectly satisfactory in service. My only note of caution

is that my first brand-new Phoenix crank’ was supplied with one big-end journal

10 thou’ undersize. Happily, the item was immediately replaced without any

quibble and subsequent ones have been spot-on, but nowadays I always check.

Interestingly, I recently checked the big end journals on my original Phoenix

crank’ after it had propelled a variety of A7s fairly enthusiastically for more

than 20,000 miles and there was no measurable wear whatsoever.

So how do we measure big end journals? Well, when new

or reground, the business part of a journal will start life as a precision

cylinder, i.e. sides exactly parallel and constant diameter wherever measured.

However, during its working life it will inevitably wear and because the heavy

firing stroke load from the piston/conrod is applied to a particular side of the

journal every other rotation - this will eventually cause some ovality.

Similarly, any longitudinal flexing of the crankshaft can cause journals to wear

in a conical manner. Therefore, to obtain a complete picture, we must measure

the diameter of each big-end journal at six different positions. Firstly, a

reading at each end (inboard of the fillet radius) and one in the middle, with

the measurements taken at the same angle as the firing stroke load; then a

second set of readings at right angles to the first three. The difference

between the pairs of readings will reveal any ovality of the journal at each

position and it is the maximum ovality that is of interest. Next, the difference

between corresponding readings at either end of the journal will show the extent

of any taper. Finally, a comparison of the end and middle readings will

determine the extent of any ‘barrelling’.

An ideal big-end diametric clearance for a splash

feed two bearing A7 engine is probably one or two thou’. This is where a conrod

lubricated with very thin oil, will fairly easily fall under its own weight with

the big-end bolts fully tightened. This suggests to me that an ovality of up to

three thou’, and a similar amount of end to end taper or barrel shape can all be

regarded as perfectly allowable tolerances without having to re-grind the

crankshaft. Remember, whilst it may not be frighteningly expensive to have a

crankshaft reground - the cost of the necessary conrod big-end white-metaling is

considerable and several firms nowadays are quoting lead-times of three or four

months.

Earlier, I mentioned ‘crack testing’ and I use the

Johnson and Allen two part aerosol ‘magnetic ink’ method which is

straightforward and seems to work well. It is used in the nuclear industry and

by the military so, it should be OK for Austin Sevens! After thoroughly

cleaning, polishing (with emery cloth) and degreasing the relevant areas, the

Neopaint NPT16 ‘contrast aid’ white is applied and allowed to dry, which takes

only a minute or two in a warm cosy workshop. Next, thoroughly agitate the black

Neocol B black magnetic ink aerosol to ensure full dispersion of the magnetic

particles in suspension and magnetise the item to be tested. I do this by

holding a powerful magnet against the back of the area of interest with a sheet

of paper in-between, to prevent spraying the magnet and don’t forget to keep

powerful magnets well away from your pacemaker! Finally, the magnetic ink is

sprayed onto the component surface and a careful visual inspection in good light

will reveal the presence of any crack, as a discernible black line. This method

is applicable for crack testing many other ferrous components including A7

conrods and will be referred to again in the next section. Obviously, if a crack

is detected, then the crank’ should no-longer be considered suitable for use.

Conrods

If money is no object or you are building a

racing engine, then I imagine it might be nice to have brand new conrods and

several different manufacturers now offer suitable rods for our engines.

However, I took expert advice some years ago that recommended sticking with

Austin rods for road use (including enthusiastic use) so long as they have been

carefully selected and equalised. My experience suggests this advice was sound

because I have not yet broken a conrod and many of the failed ones I have seen

were damaged for other reasons such as crankshaft failure or piston breakage.

Interestingly, I have seen terribly damaged A7 engines where the conrods have

bent but not broken which might suggest they are stronger than they look.

So how do I select conrods? I firstly check the fit

of a new gudgeon pin in the little-end, it must be a firm push fit with

absolutely no slackness, then check that the little-end pinch bolt thread is

sound. In my view, these checks are of the utmost importance because I have seen

several engines where poorly fitting gudgeon pins have caused considerable

fretting to the securing bolt. If this is left unattended, the engine is almost

certainly doomed to failure. I always use new HT bolts on assembly with internal

shake-proof washers and a touch of thread-lock - all tightened very firmly (this

will be covered in a future article).

I also file smooth and polish any potential stress

raising marks on the flanks paying particular attention to the top of the web

just below the little-end where many rods can be found to have cracks. The rods

are then crack tested in this area using the Johnson and Allen two part aerosol

‘magnetic ink’ method described earlier.

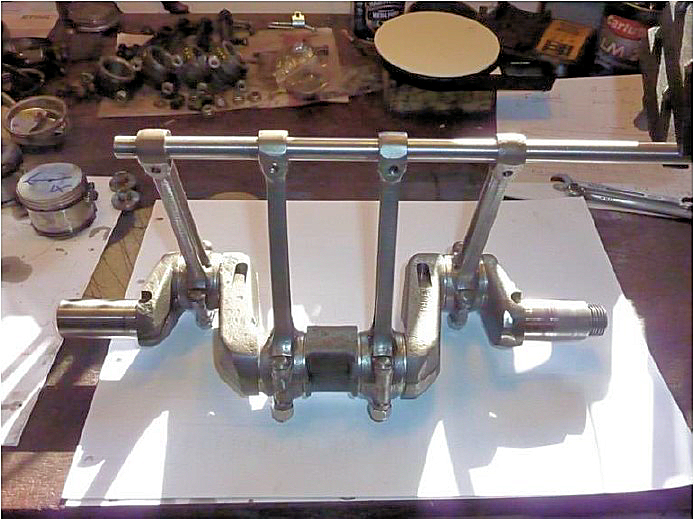

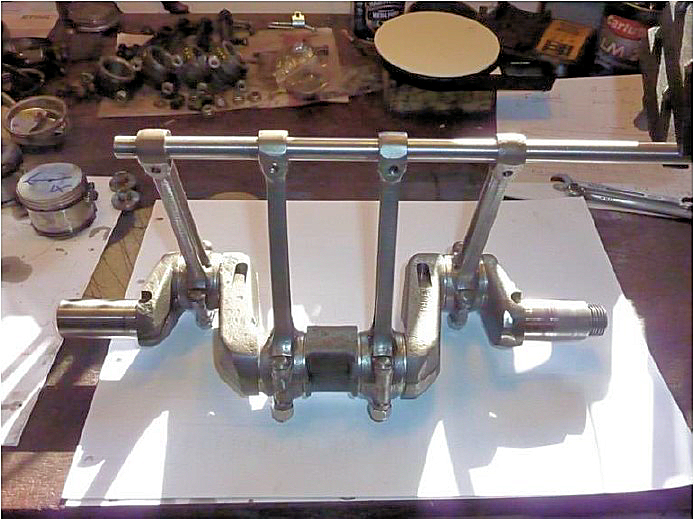

Readers with an excellent memory, will recall the

January 2014 Newsletter article containing a photo showing how A7 con-rods can

be simply checked for fore and aft bending or twist, by passing a length of

0.500” diameter ground Silver Steel through all four little ends with the rods

firmly attached to the crankshaft. For new members and those with an imperfect

memory, we have a similar photo here. The rod should be a firm sliding/twisting

fit without any binding or loose play.

Eddie assures me that slightly bent rods can be

straightened satisfactorily. Very slight adjustments by cold twisting or bending

are considered permissible. Usefully, the Dorset A7 Club website Technical Pages

show how rods can be straightened using a vice as a press.

A later article will discuss engine assembly in

detail, but it is perhaps useful here to mention that I favour being able to

pass the conrods down the bores. This usually necessitates filing away the

‘bumps’ either side of the conrod big-ends if the bores are smaller than +60.

This filing can often usefully be incorporated in the process of equalising the

weights of the four rods. At this stage, it is also useful to ensure the big-end

rods and caps are permanently marked to ensure correct positioning on

re-assembly.

Fitting conrods to crank’ journals is straightforward

in an existing engine where the journals are within limits and the white metal

in the big-ends is sound. After thorough cleaning and careful inspection of the

white-metal for cracks or other damage, the rods should be clamped in position

on the crankshaft after lubricating the journals with light oil. I keep a set of

old Nyloc nuts for this purpose and save a set of new ones for final assembly.

Interestingly, it appears there are two different depths of 5/16” Nyloc nuts on

the market and I prefer the slightly deeper ones because a socket fits more

securely without binding on the cap. So, after torqueing the nuts to the

required 18 lb ft and rotating the rod a few times to disperse the oil, check

that the rod will happily fall from the horizontal under its own weight but

without undue radial slackness. Slight (around 1/16”) fore & aft (rocking) play

at the little-end is OK in my view. If the rod seems just a little too slack, it

can be dismantled and the big-end mating surfaces rubbed on fine wet & dry paper

supported on a truly flat surface, then cleaned and reassembled. Finally, give

the big-end cap a reasonable thump via a stout brass drift and you might find

this results in a better journal fit. If the big-end still seems slack the

process can be repeated.

On the other hand, if the journal is a bit too tight,

it will be necessary to indulge in the ‘dark-art’ of bearing scraping. I say

this, because having discussed the subject over the years with a number of

experienced practitioners, I have come to the conclusion that there are several

different approaches. Anyway, the method I use (which happily seems to work) is

as follows:

1. Prepare a ‘jig shaft’,

ground to the required journal diameter plus the required bearing clearance. In

our case say plus one to one and a half thou’ on diameter. Note: if you use the

crank journal directly instead of a jig, you will end-up with insufficient

clearance in the finished big-end bearing

2. Coat the jig shaft very thinly with engineer’s

blue

3. Clean the conrod white-metal and bring it firmly

into contact with the jig shaft and rotate it gently right around

4. When separated, the high spots on the conrod

white-metal will be marked grey/blue

5. Use a sharp scraper to carefully remove these high

spots, scraping alternately at plus and minus to the centreline of the bearing

journal

6. Repeat from Step No 2 until the blue marking

covers more than 75% of the white-metal

7. Repeat the whole marking and scraping exercise for

the big-end cap

If the above process has been

carefully carried-out and the conrod is cleaned, lubricated and assembled on the

crankshaft, it should now happily fall from the horizontal under its own weight.

Alternatively, if we are building an engine with a

new conrod/crankshaft combination, then the conrods will have to be white

metaled and machined to suit the crankshaft journals. Sadly, the days are gone

when every town had its own white-metal business and the relatively small number

of remaining providers seem rather expensive. More irritating, is that some

outfits now quote lead times of up to four months, which can be very

inconvenient. Incidentally, I’m sure readers will recall that the September 2017

issue of this Newsletter contained a useful list of white-metal specialists in

the South of England (thank you Ray).

Now, I have known people who have had white-metaling

done without specifying exactly what they want. This might be OK if the firm is

very well acquainted with Austin Sevens but I always make sure to specify the

following:

o One to one and a half thou’

diametric clearance at mid journal

o An extra thou’ or so ‘bellmouth’ at each end of the

journal

o Eight to ten thou’ longitudinal clearance along the

crank journal (Woodrow suggests as much as 60 thou’ which seems rather a lot to

me)

My approach gives a slightly

looser engine than some firms might provide if left to their own devices but is

based on advice I received many years ago from a very well respected authority

on A7s.