Please note that modern slipper pistons offer limited scope for this

modification because, as mentioned earlier, they have a shallower land above the

top ring than most ‘full skirt’ pistons.

Please note that modern slipper pistons offer limited scope for this

modification because, as mentioned earlier, they have a shallower land above the

top ring than most ‘full skirt’ pistons. AUSTIN SEVEN ENGINE REBUILD

Article kindly reproduced from the Herefordshire A7 Club.

PART 7 - RE-ASSEMBLY

Part 1 – The crankcase, camshaft, oil pump, rear main housing.

Part 2 - The cylinder block and connecting rods

Part 3 - Crankshaft & con rods

Part 5 - Carburettors, manifolds, clutch and fan spindle

Part 8 - Attaching the block and cylinder head

ENGINE RE-ASSEMBLY

Numerous books and articles have been written telling us how to assemble an Austin Seven engine and the ones I have found most helpful are Woodrow’s A7 Manual, Notes from a series of lectures by Jack French - Pages 126 et seq of the 750 Club’s A7 Companion, some elements of Chapter 2 in Bill Williams book ‘A7 Specials’ and pages 37 to 42 of the Practical Classics ‘Austin Seven Briefing’. The following notes are not intended to be a complete start-to-finish treatise on A7 engine assembly but rather a collection of points that I believe are important

.

FITTING THE

CRANK

Assuming the

crankcase and the front main bearings have been prepared, we can start by

fitting the crankshaft. The crank is threaded through the rear main bearing

aperture after the front of the crankcase has been thoroughly warmed-up, for

which I use a hot air gun. With the crankcase sitting vertically on its

bell-housing and the tail of the crankshaft supported in roughly its final

position on a hardwood block, the front angular contact bearings can be

carefully tapped into position (over the front of the crankshaft and into the

front main bearing housing) with the faces marked ‘thrust’ facing one-another

and all surfaces lightly oiled. If everything is spotlessly clean, the crankcase

hot to the touch and things reasonably well-aligned - the bearings can now be

coaxed into position using a brass drift and a medium weight hammer without the

need for any heavy blows. If you are too heavy-handed, you risk damaging the

retaining lip in the crankcase or the balls marking the races which could give

the engine an irritating rumble from day one.

The bearings should

carefully be driven fully home against the retaining lip – then, if you have

used the correct bearings (and spacers if required), the outer front race will

protrude a little above its housing. The bearing retaining plate can then be

fixed in position, together with its locking tab washers.

The front crankshaft

timing gear is then slipped into position (boss first) taking care to ensure

that the small woodruff key stays in position. A new tab washer follows and I

find it useful to first bend-up the tab extremity a little with a pair of

pliers. This doesn’t affect the fitting of the ‘starting’ nut but greatly

facilitates locking the tab when the time comes.

With the front

bearing retaining plate secure and the starting dog nut firmly tightened (but

the tab not yet locked), we have a seriously exciting moment. Because, by trying

to waggle the free rear end of the crankshaft by hand, we will immediately

discover whether the A/C bearings at the front of the engine (whether brand new

or adjusted as described in an earlier Part have the correct pre-load. There

should be no detectable ‘waggle’.

It is useful at this

stage to temporarily pop the cylinder block into position to check that the

big-end journals of the crankshaft align centrally with the cylinder bores. This

will confirm whether the combination of crankcase, front A/C mains and spacers

(if any) is correct. Assuming everything is in order at the front, we can direct

our attention to the rear main bearing. It is essential that the inner race is a

good fit on the crankshaft and that the bearing housing is not damaged or

distorted. If the housing is warmed-up it will help us drive (or press) the

outer race fully-home, this assembly can then be fitted into the back of the

crankcase - sandwiching the thinner of the two gaskets (smeared with a thin coat

of Blue Hylomar or similar) making sure the housing and gasket holes align

correctly with the tapped holes in the crankcase. At this point we must also

check that the oil drain hole is correctly aligned with the return drilling in

the crankcase and free of any stray sealant. The inner race can now be drifted

into position firmly against the rear flange of the crankshaft taking care that

the rollers enter the outer race happily without tipping or binding. The oil

thrower (with appropriate indents) is now positioned with the dish side facing

away from the engine. The oil retention plate follows, and my preference is for

one that contains a modern lip-seal. This sits on the thicker of the two gaskets

(again with a thin smear of sealant) and the whole lot then secured in position

with the four shallow head set screws and locking tab washers. Shallow head

screws are important, because normal size heads would foul the flywheel when

fitted.

That completes the installation of the crankshaft except for locking the front timing pinion tab washer which will follow later.

FITTING THE BLOCK

Our cylinder blocks

have been around for over eighty years and may well have had their top surfaces

skimmed at some stage – so, I believe it is vitally important to check the

clearance above the pistons before continuing with final assembly.

This trial assembly

obviously requires that the pistons be attached to their con-rods but there is

no need at this stage to fit either the little-end bolts or piston rings and I

use an old set of big-end bolts and nuts.

For two-bearing A7

engines, if either the top face of the cylinder block has been machined, or

significant lapping has been carried out on the top surface of the crankcase,

then a trial assembly will reveal whether there is sufficient clearance over the

pistons. This may not be critical if you plan to use an early low-compression

head but essential if you aspire to a high compression top-end, such as a ‘1937

A7 head’ or one of the proprietary (often aluminium) varieties. It seems that A7

engines when new had a clearance above the piston crown at TDC to the top

surface of the block of around five to ten thou’. This, together with a good old

fashioned Copper/Fibre head gasket of about fifty thou (compressed) thickness,

would allow a standard Austin two-bearing crankshaft to rev to around 6,000 rpm

(for a short while anyway) without pistons two and three hitting the head due to

crankshaft whip. Unfortunately, some modern copper/asbestos head gaskets are as

thin as thirty thou’ so the clearance over the pistons needs to be assessed and

corrected to between five and ten thou’ if necessary. This is most easily

achieved by adding an aluminium shim plate of appropriate thickness between the

block and the crankcase. These shim plates are available in various thicknesses

of typically 10 and 20 thou’. Incidentally, they may appear to be a regular

pattern that can be fitted either way up - but one I used recently was a much

closer match to the top of the crankcase one-way rather than when flipped over.

Definitely worth checking.

Another option for

increasing the clearance above your pistons, is to machine a small amount off

the piston crowns. Whilst this might be perfectly feasible for earlier type

pistons - it is inadvisable in my view for modern slipper pistons, because they

have only a very shallow land over the top ring. Anyway, the whole idea of

machining pistons and then making sure they are exactly identical in weight has

never really appealed to me. Happily, crankshaft whip is believed to be less of

a problem with modern replacements, so the proud owners of these desirable items

can perhaps get away with a lower clearance than suggested above.

One other influence

here is whether or not a gasket is used between block and crankcase and if so,

what type. Well, for years I used the traditional paper gasket typically having

a compressed thickness of only a few thou’, assembled with a thin smear of Blue

Hylomar on each surface and that was generally fine. However, I now take great

care to ensure the mating surfaces of the block and crankcase are both

beautifully flat and carefully de-greased, then using only a thin smear of

Hylomar has proved very successful, with no oil leaks and the block holding-down

nuts staying tight. Of course, if you are introducing a shim plate, you will

need to apply sealant to both sides. I did assemble one engine with a silicone

gasket and whilst it certainly remained oil-tight, I noticed that the

holding-down nuts regularly needed to be tightened. It seemed the silicone was

gradually migrating under load despite having been assembled dry on de-greased

surfaces as per the instructions. The problem was that the tightening affected

the tappet clearances which consequently needed adjustment.

As mentioned in

earlier Parts, the theory of fluid dynamics suggests that the movement of gasses

into and out of the engine will be improved if the sharp edge of the block

leading into the bore is slightly rounded. The key limitation is of course the

position of the top of the upper compression ring at TDC and this can usefully

be determined during our trial assembly. I then allow, say, an extra 20 thou’ to

be safe. The width of any chamfer or rounding should obviously be limited to

correspond with the head gasket dimensions and all four chamfers should be

identical. Please note that modern slipper pistons offer limited scope for this

modification because, as mentioned earlier, they have a shallower land above the

top ring than most ‘full skirt’ pistons.

Please note that modern slipper pistons offer limited scope for this

modification because, as mentioned earlier, they have a shallower land above the

top ring than most ‘full skirt’ pistons.

Having made sure

that our pistons won’t collide with the head and created any required chamfers –

we can now get-on and complete the engine.

Piston ring gaps

New piston rings are

normally supplied to fit the bore size with virtually zero clearance, so, we

usually need to file away a small amount of material to obtain the desired gap.

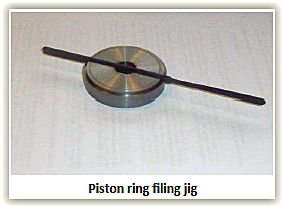

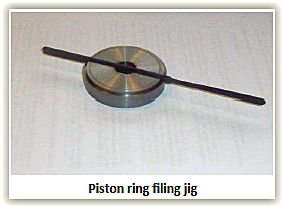

I do this using the

simple jig shown

in the photo

that has an accurately cut, centrally located vertical groove which is a snug

fit to a thin flat ‘Swiss’ file. The ring is held on the jig by hand and

squeezed to close the gap gently against the file. Proceed carefully with the

filing because rings are fragile and it’s very easy to remove more material than

intended.

Ring gaps are

conveniently assessed by supporting the ring on an old piston to ensure it sits

exactly square to the bore - then removing the piston and measuring the gap with

feeler gauges. The gap is measured at both positions of interest and the

measurements should be virtually identical.

There are two

fundamentally different approaches to assembling A7 engines. The conventional

method described in many books is to fit the piston & conrod assemblies in the

block with the oil baffles in-place on the rods, then bring the block and

crankcase together on the gasket if using one. However, I find this a right

fiddle and very much favour ensuring that the conrod part of the big-ends can

pass down the cylinder bores, which makes things much more straightforward.

Con-rods & pistons

Pistons can now be

fitted to the con-rods remembering that it is essential the gudgeon pins are a

firm sliding fit in the little-ends whilst not binding at all in the pistons.

The grooves in the pins must be carefully aligned to admit the little-end screws

and this can usually be achieved by hand, although Woodrow shows a suggested

tool that can sometimes help. I always use new HT little-end screws with

internal shake-proof washers together with a medium strength Loctite on

degreased threads but care must be taken to prevent any Loctite from finding its

way onto the gudgeon pin.

Little-end screws

often have fairly shallow (often slightly domed) hexagon heads and must be very

firmly tightened. This is greatly facilitated by using ‘buttons’ such as those

described in Woodrow to hold the pistons in the vice and I use a high quality

combination spanner with one face ground flat to maximise engagement with the

hexagon head of the screw. Interestingly, there is much better access to the

little end screw with ‘slipper’ type pistons.

Bill Williams is one

of the few sources of information that tells us that the little-end bolt heads

should face towards the off-side of the engine although this might be Longbridge

tradition rather than cunning design. Also, if you are using split-skirt

pistons, the split should face towards the camshaft (near-side), but this is

more obvious from first principles.

The piston rings can

now be fitted to the pistons and most suppliers provide us with clear

instructions. However, this is not always the case with some products from the

far-east. For example, a recent set of slipper pistons with one oil control, one

(dark finish) scraper and one (shiny) compression ring were supplied without any

instructions. The rings were helpfully marked to show which surface faced ‘top’

but the two top rings shared identical dimensions and it was unclear which went

where. It turns-out that the shiny one was the compression ring and should be

fitted in the top groove.

Fitting rings is a

straightforward process, but care is needed to avoid scratching the piston lands

and sliding the rings over thin brass shimstock can help. Interestingly, modern

pistons with narrow rings (thus lower contact areas) are designed to give lower

bore contact pressures than their conventional counterparts. This has the

obvious advantage of reducing friction and happily, makes them a little easier

to fit.

FITTING THE CAMSHAFT

If your timing gears

have enjoyed a happy former life in the crankcase yo u plan to use, we can skip

the next step. Otherwise, it will be necessary to select a pair of suitable

gears. If you are lucky, there will be an original Austin dimension stamped at

the top front of the crankcase that indicates the departure from standard of the

dimension between the camshaft and crankshaft bore centrelines. You will be even

luckier if you can find a pair of timing gears that correspond, also,

unhelpfully, some gears are unmarked. In this case it will be necessary to mix

and match from a collection of spares from your own and your friends spares,

avoiding badly worn specimens if possible and obtain satisfactory meshing by

trial and error.

u plan to use, we can skip

the next step. Otherwise, it will be necessary to select a pair of suitable

gears. If you are lucky, there will be an original Austin dimension stamped at

the top front of the crankcase that indicates the departure from standard of the

dimension between the camshaft and crankshaft bore centrelines. You will be even

luckier if you can find a pair of timing gears that correspond, also,

unhelpfully, some gears are unmarked. In this case it will be necessary to mix

and match from a collection of spares from your own and your friends spares,

avoiding badly worn specimens if possible and obtain satisfactory meshing by

trial and error.

We must now set the

longitudinal clearance of the front camshaft bearing. This is achieved on the

bench by bolting the cam pinion in place and measuring the clearance with a

feeler gauge. We are aiming for a clearance very close to two thou’. This is

important, because a larger clearance will almost certainly cause the engine to

emit a rumble. It is easy to reduce this clearance by rotating the camshaft gear

on its taper with a little fine grinding paste, then scrupulously cleaning

everything and trying again. If, however, there is insufficient clearance, a

very small amount can be removed from the back face of the gear in the lathe.

If the rear camshaft bearing has been removed for inspection and cleaning, it should now be refitted into the back of the crankcase on a thin gasket with a touch of sealant taking care that the lubrication hole lines-up correctly with the horizontal oil feed gallery.

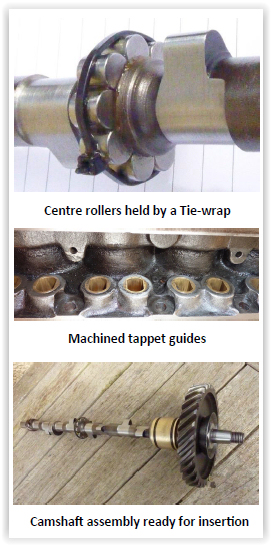

It is now time to install the camshaft and for years

I used to simply stick the centre camshaft rollers in-place with Heavy Grease

and that worked really well. However, I cannot find a supplier nowadays and

typical general purpose grease is too feeble. So, I use a small tie-wrap to

hold the rollers in place as can be seen in the

photo.

Incidentally, the

photo clearly shows that this particular camshaft has had the base circles

ground to give nearly 70 thou’ of additional lift (actually a Pigsty Trials cam)

and because the smaller base circles allow the tappet blocks to drop a bit

lower, there is a risk that the adjusters might clash with the tops of the

tappet guides. Therefore, it is a good idea to mill some material from the tops

of the guides as shown in the photo on the left if using a high-lift camshaft.

Once the assembly is

ready as shown, it can carefully be inserted into the crankcase taking care not

to dislodge the centre bearing rollers. The rear bearing spigot should be

lubricated and the 5/16” BSF threaded hole in the front bearing carefully

aligned with the corresponding hole in the crankcase. Then, the whole assembly

is pushed firmly into position whilst rotating the shaft to help the centre

rollers enter the outer race. As this happens, the tie-wrap holding the rollers

will be pushed clear and can be snipped off.

Finally, the

securing setscrew (as described in earlier Parts) is tightened onto a fibre

washer (or even better a Dowty washer) to ensure the camshaft is firmly held in

position and there are no oil leaks.

We must now check

with a straight edge that the two timing gears are in line with one another. Any

necessary correction can be achieved either by adding shims or machining a small

amount from the rear boss of the crankshaft pinion. When correct alignment has

been achieved, the crankshaft ‘starting nut’ can be very firmly tightened and

its tab washer locked.