AUSTIN SEVEN ENGINE REBUILD

Article kindly

reproduced from the Herefordshire A7 Club.

Part 2 - The

cylinder block and connecting rods

Part 1 – The crankcase,

camshaft, oil pump, rear main housing.

Part 3 - Crankshaft & con rods

Part 4 -

Main Bearings

Part 5 -

Carburettors, manifolds, clutch and fan spindle

Part 6 - Flywheel

Part 7 -

Reassembly

Part 8 -

Attaching the block and cylinder head

Cylinder block

Happily, there still seem to be quite a few Austin

Seven cylinder blocks around but sadly they are not all in useable or

recoverable condition. Many problems with blocks can be overcome so how do we

select one that is suitable for use in an engine rebuild? Well, the first thing

I check is that there are no cracks running radially from the centre head stud

towards bores two and/or three. This fault is not uncommon and is probably

caused by severe overtightening of the head nuts - more of which in a later part

of these notes on engine assembly. The centre head stud has less supporting cast

iron than the others and is even more vulnerable if the nearby bores have been

fitted with liners. Unfortunately, if cracks are present here, I believe the

block should be consigned to the bin.

Bores

First, we need to consider the condition of

the cylinder bore surfaces and I check to see if there is any evident damage

such as vertical marks or gouges from a loose gudgeon pin or patches of very

thin wall. I have seen examples of both and such blocks need to be bored and

liners inserted before use. The process of fitting liners definitely requires

expert attention to get a satisfactorily result and even then, many builders of

sporty A7 engines avoid lined blocks.

The most obvious indicator of excessive bore wear is

the existence of a ridge above the top piston ring on the off-side of the block.

A slight ridge can often be honed away but a noticeable ridge might suggest

significant wear that requires a re-bore.

If the cylinder bore surfaces appear in good shape we

next need to check the bore dimensions and if you are the proud owner of a

proper bore gauge this is very straightforward. The rest of us probably need to

adopt a more basic approach based on measuring the clearance between a piston

and the cylinder wall. So, how do we make the necessary measurements? Well,

there are four key diameters to measure on each cylinder, the longitudinal and

transverse diameters close to the top and bottom of each bore. This can be

achieved by using a reasonably well fitting piston together with a set of narrow

feeler gauges. Clearly, it is important to use a consistent part of the piston

for this process in order to obtain comparable results because pistons often

have a variety of different diameters. The aim is to establish any ovality near

the top of the bore and compare it with that at the bottom. It is normal to find

very little ovality low down in the bores because of generally lower sideways

piston loads and better lubrication. The ovality that matters is found towards

the top of the bore and some sources recommend a re-bore if the ovality here

exceeds twelve thou’ but personally, I would be looking to re-bore the block if

this ovality was greater than say six or eight thou’.

The other feature of interest is the top to bottom

transverse taper because even at 8 thou’, this causes the ring gaps to change by

around 12 thou’ twice for each revolution of the crankshaft and I believe this

is undesirable.

If you decide a re-bore is required, it is important

to provide the pistons you intend to use and state the required piston to bore

clearance. Also, the bores should be brought to their finished dimensions by

honing which gives an excellent surface to hold oil – essential whilst

running-in.

Pistons

There are three distinct types of piston that

we commonly use in our engines –

o Cylindrical split skirt – Ideal for touring engines

with two compression and two oil control rings, happy to operate with low radial

clearance (say three thou’ on diameter) giving good control of oil consumption.

Sometimes thought to be insufficiently strong for highly tuned engines, although

I have had very satisfactory results in moderately tuned road engines

o Cylindrical solid skirt – Until recent years the

go-to piston for sports engines, again with four rings as above but needs a

little more diametric clearance – typically four or five thou’. May use more oil

but very strong

o Cut-away sports slipper – These modern pistons have

two often narrow compression rings and a single oil control ring all above the

pin. Supplied in a variety of metric dimensions and considerably lighter than

the above types therefore happier at high rev’s. The ones I have seen have

relatively narrow lands and this restricts the amount of chamfer that can be

applied at the top edge of the bore. I have no personal experience of this type

but I am told they can cause higher oil consumption

Head and manifold

studs

The studs in A7 blocks are often difficult to

remove. This is no surprise, because the buried ends have been in contact with

engine coolant (sometimes for many years) thus causing some inevitable

corrosion. It is highly unusual to be able to remove studs by using two nuts

locked together, unless they have recently been replaced. So, we have to

consider other options - and these range from a rather basic approach using a

good size ‘monkey’ wrench or Stilson to the various forms of proper stud

extractors.

Stilsons can be effective, especially if used as a

pair at 180 to one another but they will often damage the studs - which of

course doesn’t matter if you plan to replace them. Undoubtedly, the best method

of removing studs, is by using a proper stud extractor tool and several

different socket-drive types are available. The cheaper ones are based on an

eccentrically mounted hardened & knurled steel ring that grips the stud and they

can accommodate a range of stud diameters. However, undoubtedly the best ones

are the ‘roller cage’ type but they are rather expensive and you need a separate

one for each diameter.

In all cases, it is helpful to lean repeatedly on the

socket wrench or drive bar until you eventually feel it ‘give’. The application

of heat to the stud can sometimes help release more stubborn examples .

.

Sadly, despite all our best efforts, it is not

uncommon for manifold and sometimes head studs - to break rather than allow

themselves be unscrewed - and the break will invariably occur just below the

block surface. Now, many books tell us that in this event - you simply

centre-pop the broken stud remnant near its centre, drill a suitable hole and

use a left-hand screw extractor to remove it. I strongly suspect that these

writers are simply repeating something they have read but never actually tried

to do it themselves. I’m afraid that I have had only very limited success with

this approach.

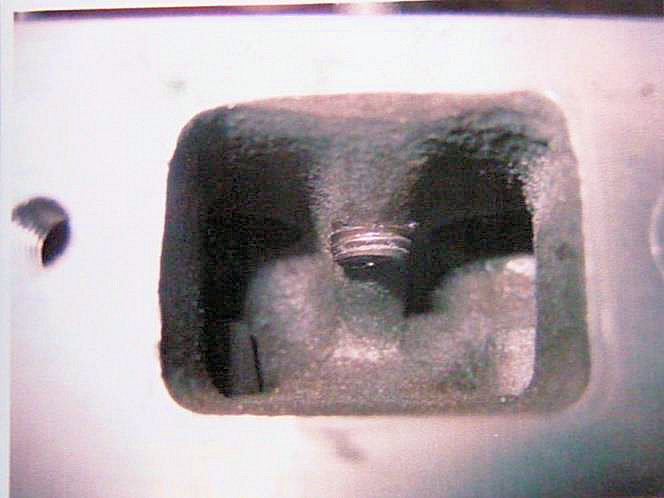

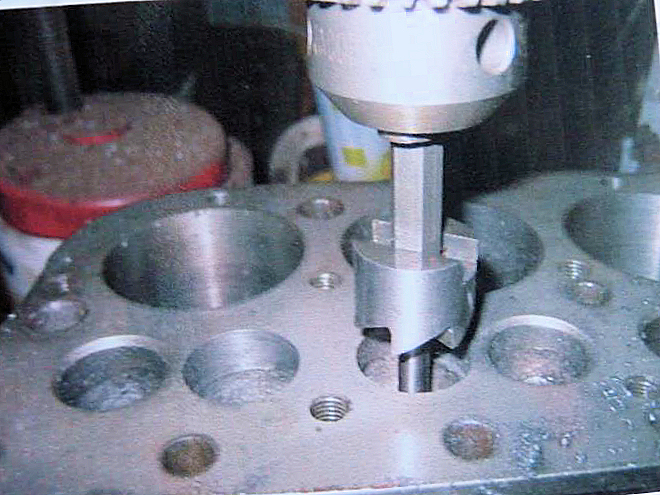

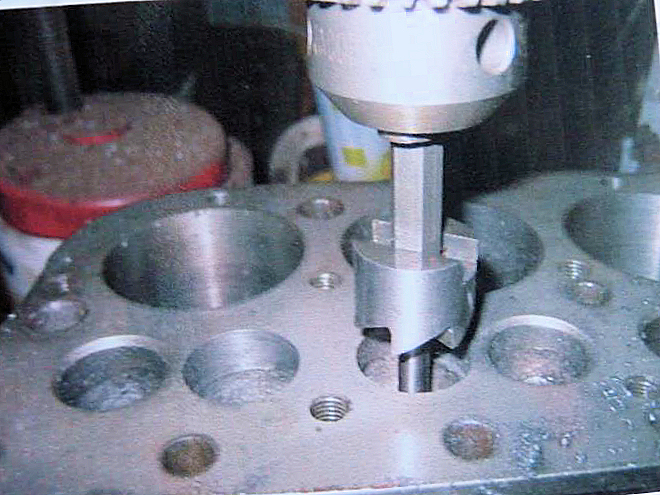

My method of removing broken studs is simple and

so-far, has always been successful. For head studs I use an old cylinder head as

the primary jig, in conjunction with a steel guide ferrule sitting in the

appropriate stud hole. The remains of the stud should be filed flat with the

mating surface if it protrudes, then the head secured in position with at least

three or four other studs & nuts before inserting and pressing-down the ferrule

and drilling-out the core of the offending stud.

Many years ago I turned-up several ferrules to suit

5/16” BSF head studs. The one shown on the left is 1/8” internal diameter and

the outside diameter is sized to fit the 5/16“ dia stud hole in the head. It is

important that the ferrule is a close sliding fit in the stud hole and the drill

a good fit in the bore, also the ferrule must reach down to the top surface of

the block. A second ferrule is then substituted to take a 5/16” BSF tapping

drill - 7/64” dia will do.

Very often, after drilling, the remains of the old

thread will fall-out or easily be coaxed out. Finally, a carefully aligned

‘second’ tap will quickly restore the thread to a usable condition.

Broken manifold stud threads can easily be repaired by

an entirely equivalent method, with appropriately sized jig ferrules and an old

Austin manifold.

I believe it is essential that all threads in the

block are in good condition, so if you are unhappy with the results of the above

process, or the threads are loose, then stepped studs are probably the answer

and they are widely available from our usual suppliers. Several other approaches

are discussed in Part 1 of these notes. In any event I would always advocate

replacing with new - any studs that do not have excellent threads.

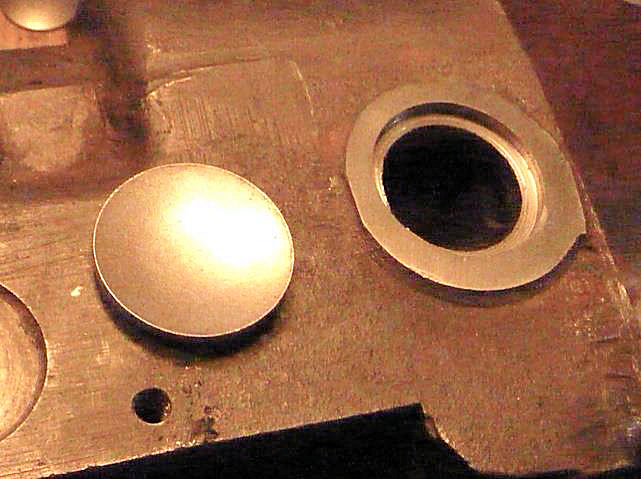

Core plugs

If you are lucky enough to have an early

cylinder block with screw-in core plugs – you can skip this section.

Unfortunately, the more common ‘knock-in’ core plugs can appear perfectly OK but

in-fact be wafer thin due to internal corrosion. So, unless I’m sure the core

plugs have been replaced in recent years and therefore known to be sound, I

believe it is prudent to replace them with new when rebuilding an engine. It is

also much easier to clear the internal water passages of the block with the

plugs removed.

Core plug removal is normally straightforward - you

simply drive a small sharp cold chisel through the centre and lever out the

remains.

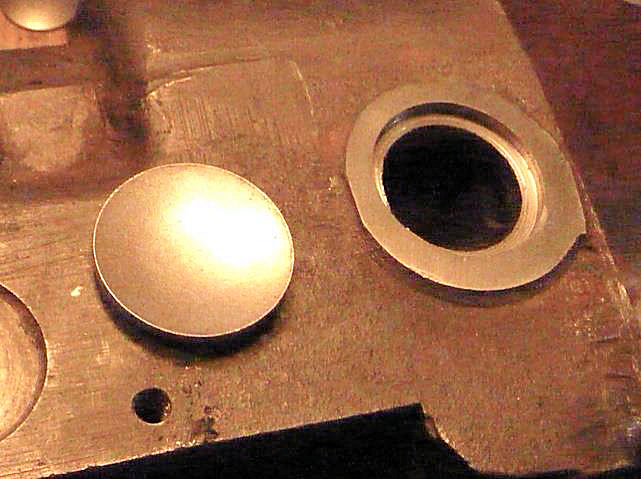

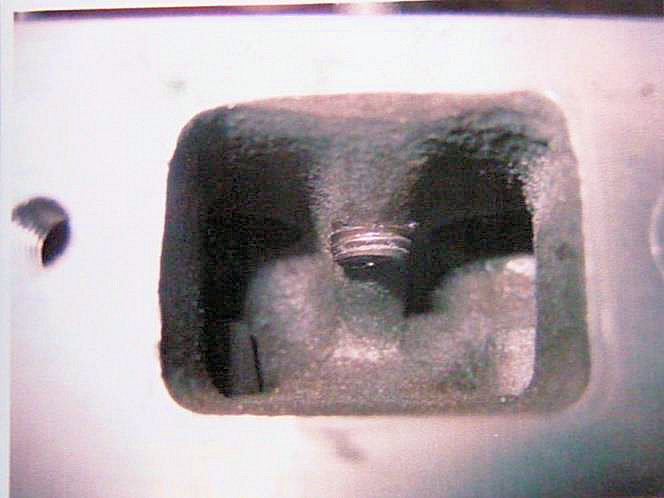

Many years ago I had a core plug fail not long after I

had replaced it, and the problem seemed to be a badly corroded housing. So,

nowadays, I always ensure the seating is thoroughly sound before assembly. The

seat shown here in the photo was machined a little deeper (there is plenty of

metal to accommodate this) using a boring head with the block clamped

upside-down on the bed of a Myford 7 Series lathe with suitable spacers. This

provided a perfect seat.

Some new core plugs have a corrosion resistant plated

surface but if this is absent, then it is prudent to apply some protection to

the inner surface. A two-part epoxy paint would be ideal. The proper

installation process for domed core plugs is well known - using a steel drift,

slightly smaller in diameter than the plug and the plug placed (concave side

down) on a thin bead of 2-part epoxy putty. Then quickly follow-up with a

whopping blow f rom a heavy hammer (sometimes several) but definitely not a

series of gentle blows.

rom a heavy hammer (sometimes several) but definitely not a

series of gentle blows.

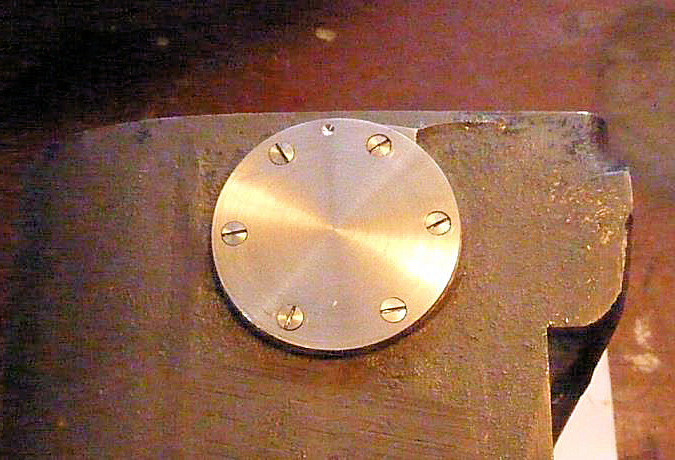

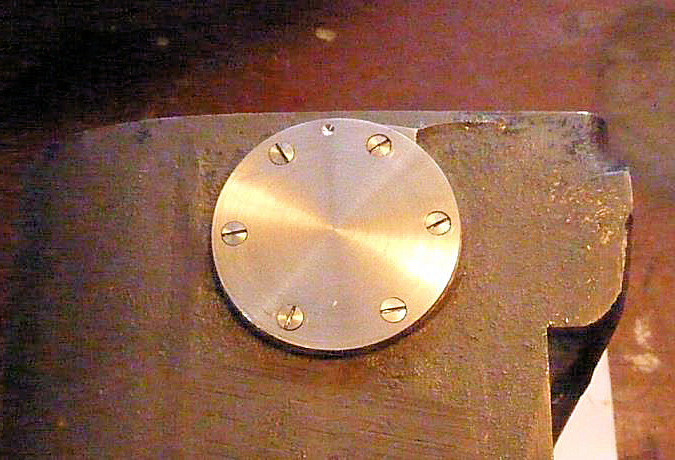

For core plugs in the block, I adopt a belt and braces

approach to completely eliminate the likelihood of any further problems by

adding steel cover-plates (see photos). The plates are about 1/16” thick -

sealed in position on a gasket smeared with Hylomar and finally secured by six

6BA x 3/8” long countersunk steel setscrews. Yes, I know what you are thinking

and I agree - this is probably completely unnecessary but I am determined never

to have another a core plug problem!

Interestingly, I recently heard of another risk averse

engine builder who used to install a second core plug on top of the first -

something I’ve never seen in the text books but certainly a lot quicker than my method.

a lot quicker than my method.

Coolant passageways

The water passages in A7 blocks are often

restricted by hard rust deposits which need to be cleared if we are to avoid an

engine that boils when climbing long steep hills on sunny days. Most of this

obstructing material can be removed by poking around with a hardened blade

through the side water inlet opening but the worst affected region is likely to

be the ‘hot side’ adjacent to the exhaust manifold. Luckily, there is an

excellent article on the A7OC website dealing with this very subject, that

recommends appropriate drill sizes and depths to clear this part of the block

(and head). It is also important that when the manifold studs are installed,

they do not protrude into these newly cleared areas.

The cast iron ‘bridges’ supporting the side water

inlet mounting studs are often badly corroded. If the ‘bridges’ are largely

intact but the 5/16” BSF stud hole threads are in poor condition, it is often

possible to drill and tap say 7/16” x 26 TPI and turn-up a pair of bushes (I use

bronze) threaded externally to suit and internally 5’16” BSF as shown in the

following photos.

The bushes are fixed in position with high strength

Loctite and after curing – cut and filed flush with the flange surface as shown

in the photo on the left.

I have used this method several times and it has

proved entirely satisfact ory. However, if the ‘bridges’ are badly damaged or

non-existent and you are desperate to retain your favourite block – then all is

not lost, because laser cut stainless steel repair plates are now available.

ory. However, if the ‘bridges’ are badly damaged or

non-existent and you are desperate to retain your favourite block – then all is

not lost, because laser cut stainless steel repair plates are now available.

There is an excellent article by Colin Danks on the

Bristol A7 Club Website …. http://www.ba7c.org/ (with photos by Terry Griffin)

that describes in detail the fitting of a repair plate.

In essence, the plate is fixed in position with

stainless steel countersunk set-screws on a gasket with sealant. The plate is

not really thick enough to thread for the 5/16” studs, so nuts (preferably also

stainless) need to be silver ’soldered’ on the back. Any remaining ‘bridge

remnants obviously need to be sawn off to clear these nuts. Austin’s

standard ¼”diameter manifold studs have always struck me as being slightly

flimsy - so, I make mine 9/32” diameter, threaded BSF and make nice beefy 7/16”

AF brass nuts to suit. Much better engineering in my view and I like to think

that Sir Herbert wouldn’t be too disapproving!

Block to crankcase

fixings

The cylinder block is attached to the crankcase by

eight 5/16” BSF studs and for normal use with single valve springs and a

standard camshaft this is probably adequate so long as the threads in the

crankcase are in good condition. However, if like me you like your engine to

develop a little more power, you might employ a camshaft that gives a little

extra valve lift and to fully exploit its potential, you will frequently want to

employ high engine revs which calls for double valve springs. All this suggests

to me that those eight studs might appreciate a little help especially in the

areas at either end of the camshaft. I have seen a variety of solutions over the

years that include bolts running from inside the crankcase to different patterns

of external brackets some of which struck me as decidedly clumsy.

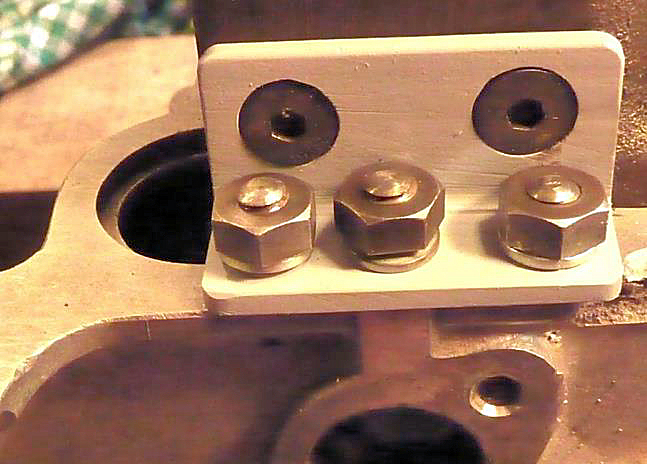

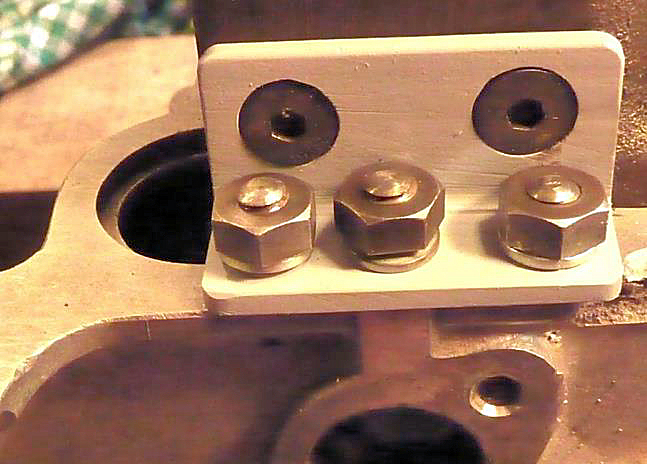

My approach is to attach simple mild steel brackets at

the front and back of the engine above the line of the camshaft attached to both

the block and crankcase. Although there is not a great deal of space to

accommodate such brackets (especially at the front of the engine) or depth of

aluminium to secure them, it is possible with care to make and fit suitable items. The examples shown in the following photos are attached to the

block by a pair of 5/16” BSF countersunk hex drive setscrews secured with

threadlock and to the crankcase by ¼” BSF studs and nuts. The stud spacing of

the rear bracket looks somewhat irregular but they were positioned to maximise

the available depth of crankcase material.

suitable items. The examples shown in the following photos are attached to the

block by a pair of 5/16” BSF countersunk hex drive setscrews secured with

threadlock and to the crankcase by ¼” BSF studs and nuts. The stud spacing of

the rear bracket looks somewhat irregular but they were positioned to maximise

the available depth of crankcase material.

A very approximate calculation suggests that each

bracket provides a ‘holding-down’ capacity at least equivalent to an additional

5/16” block/crankcase stud. In any event, it seems to work because I have no oil

leakage from the block/crankcase joint despite frequently using high engine

rev’s.

Ports

A great deal of information regarding optimal

side-valve port geometry for high revving

geometry for high revving

racing

engines, can be found in the 750 Club Companion and Special Builders Guide. Much

of this is very interesting reading but for a lively road-going engine, I

conclude that generally smooth passages devoid of any sharp steps is all we

need. Depending on the choice of manifold, this probably means removing some

metal from the outer ends of the ports and making sure the gasket does not

intrude. The bottom end of the head stud immediately over the Siamese inlet

ports can also usefully be smoothed-off as shown in the following photos.

racing

engines, can be found in the 750 Club Companion and Special Builders Guide. Much

of this is very interesting reading but for a lively road-going engine, I

conclude that generally smooth passages devoid of any sharp steps is all we

need. Depending on the choice of manifold, this probably means removing some

metal from the outer ends of the ports and making sure the gasket does not

intrude. The bottom end of the head stud immediately over the Siamese inlet

ports can also usefully be smoothed-off as shown in the following photos.

I believe there is no advantage in polishing the

ports, a smooth matt finish being more desirable, although this is not the case

with the cylinder head and piston crown where a polished finish will offer some

advantage.

Valves

If the valves can be wobbled in their guides

to any extent, I always replace the guides with new.

The

old ones can easily be driven downwards for removal with a suitable stepped

drift and new ones inserted the same way, preferably with a copper washer

protecting the top surface of the guide. Better practice of course would be to

use a simply made threaded ‘puller’. With the new guides in place, it is useful

to check that a clean valve slides freely but without any play. If the valve is

tight, careful use of an expanding reamer will soon ensure a good sliding fit.

Incidentally, the guides should be positioned so that the top surface projects

3/32” into the valve port.

The

old ones can easily be driven downwards for removal with a suitable stepped

drift and new ones inserted the same way, preferably with a copper washer

protecting the top surface of the guide. Better practice of course would be to

use a simply made threaded ‘puller’. With the new guides in place, it is useful

to check that a clean valve slides freely but without any play. If the valve is

tight, careful use of an expanding reamer will soon ensure a good sliding fit.

Incidentally, the guides should be positioned so that the top surface projects

3/32” into the valve port.

The valve seat should be re-cut after installing new

guides, removing as little material as possible noting that standard seats are

45 and a seat width of around 0.10”is typical.

It seems Sir Herbert believed that standard size

valves were fine for A7 engines - and for modest power requirements, I’m sure he

was right. On the other hand, if you seek a little more oomph and are willing to

run the engine at higher revs, then fitting larger inlet valves is pretty

straightforward. A 1.00”dia cutter with a 0.275” dia mandrel to fit the valve

guide is run at slow speed to cut a depth of around 5/8” and the bottom of the

cut blended into the port with a rotating grind stone. A new valve seat is then

cut in the top face. This can with advantage be cut at 30 and only a narrow seat of say 1/16” width

is needed, because the incoming mixture tends to keep the valve and seat a good

deal cooler than the exhaust.

This can with advantage be cut at 30 and only a narrow seat of say 1/16” width

is needed, because the incoming mixture tends to keep the valve and seat a good

deal cooler than the exhaust.

Large inlet valves are available from our suppliers

and the heads are typically 1.142” (29mm)dia. I make sure there is a clearance

between enlarged inlet and standard exhaust valves on assembly of around 10 thou

and this can be achieved by carefully turning down the inlet valve head in the

lathe.

Incidentally, whilst using the lathe, the top edges of

enlarged inlets can usefully be slightly rounded to improve gas flow into the

combustion chamber. This can be seen on the top valve in the photo also the much

wider seat on the lower standard size exhaust valve.

I definitely favour valves secured with cotters rather

than pins because many years ago, I had a pin shear. I also use double valve

springs with cotter cups to suit, which allows the engine to achieve high rev’s

whilst eliminating the chance of any valve bounce.

Chamfer to top edge of

bore

If you consider the many changes of direction

of the gas path from the inlet port, up past the valve, across into the

combustion area then back out, it will be no surprise that some rounding of the

top right-angle edge of the bore will help matters. The theory of fluid dynamics

suggests that even a very small rounding will make quite a difference. The key

limitation is of course the position of the top compression ring at TDC and this

is determined by a trial engine assembly then allowing say an extra 20 thou’ to

be safe. Also, the width of any chamfer is obviously limited by the head gasket

dimensions.

Cylinder head

The low compression Austin cylinder head is

not usually associated with performance and often believed to respond poorly to

skimming in an attempt to extract more power by increasing the compression

ratio. Nevertheless, I have observed one or two early lightweight Sevens

performing remarkably well with skimmed low compression heads. Received wisdom

tells us that the higher compression (originally 5.8:1) ‘1937’ head enjoys a far

superior combustion chamber shape and in my experience it does seem to offer

more power, although I have never tried a skimmed low compression head.

Original Austin cylinder heads have now been around

for rather a long time and it is sometimes difficult to tell whether they have

been skimmed and if so, by how much. There is an excellent article on this

subject to be found on the Bristol A7 Club Website but it can be useful to know

that original heads were believed to measure within 10 thou of 1.50 inches in

height when they left the factory. Bill Williams also cautions us not to take

the compression ratio (CR) above 7 to 1 and don’t forget that increasing the

bore will also increase the CR. I will return to this subject in the final part

of these notes on engine assembly, because the compression ratio is also

affected by the thickness of the head gasket.

A variety of alloy heads are available for our engines

but I only have first hand experience of the Speedex and Supalloy offerings.

Both seem to provide a power output similar to the 1937 Austin head but have the

advantage of being considerably lighter. However, if you aspire to compete in

VSCC events, you might find you are restricted to the Watmough Hewitt head with

18mm plugs. I have heard fears that alloy heads distort and regularly need

re-facing but this is most definitely not my experience. Just for the record, I

have been using a Supalloy head (estimated CR of around 6:1) for over ten years

without any problems.

Starter housing

When fitting the starter housing , you must

fit the locating dowels because these take the strain from the mounting set pins

. The mounting set pins will always work loose if the dowels are missing , there

is quite considerable torque reaction when the starter is actuated thus the

importance of the dowels.

There is another reason for fitting these dowels, they

help to maintain correct alignment between starter teeth and flywheel teeth.

Because the starter housing is mounted directly to the

crankcase, the set pin threads are machined into soft aluminium so will quickly

wear if there is movement between housing and crankcase, to effect a repair to

possible damaged threads will always involve engine removal .

Eddie Loader

.

.

rom a heavy hammer (sometimes several) but definitely not a

series of gentle blows.

rom a heavy hammer (sometimes several) but definitely not a

series of gentle blows.  a lot quicker than my method.

a lot quicker than my method.

ory. However, if the ‘bridges’ are badly damaged or

non-existent and you are desperate to retain your favourite block – then all is

not lost, because laser cut stainless steel repair plates are now available.

ory. However, if the ‘bridges’ are badly damaged or

non-existent and you are desperate to retain your favourite block – then all is

not lost, because laser cut stainless steel repair plates are now available.

suitable items. The examples shown in the following photos are attached to the

block by a pair of 5/16” BSF countersunk hex drive setscrews secured with

threadlock and to the crankcase by ¼” BSF studs and nuts. The stud spacing of

the rear bracket looks somewhat irregular but they were positioned to maximise

the available depth of crankcase material.

suitable items. The examples shown in the following photos are attached to the

block by a pair of 5/16” BSF countersunk hex drive setscrews secured with

threadlock and to the crankcase by ¼” BSF studs and nuts. The stud spacing of

the rear bracket looks somewhat irregular but they were positioned to maximise

the available depth of crankcase material.  geometry for high revving

geometry for high revving

racing

engines, can be found in the 750 Club Companion and Special Builders Guide. Much

of this is very interesting reading but for a lively road-going engine, I

conclude that generally smooth passages devoid of any sharp steps is all we

need. Depending on the choice of manifold, this probably means removing some

metal from the outer ends of the ports and making sure the gasket does not

intrude. The bottom end of the head stud immediately over the Siamese inlet

ports can also usefully be smoothed-off as shown in the following photos.

racing

engines, can be found in the 750 Club Companion and Special Builders Guide. Much

of this is very interesting reading but for a lively road-going engine, I

conclude that generally smooth passages devoid of any sharp steps is all we

need. Depending on the choice of manifold, this probably means removing some

metal from the outer ends of the ports and making sure the gasket does not

intrude. The bottom end of the head stud immediately over the Siamese inlet

ports can also usefully be smoothed-off as shown in the following photos.  The

old ones can easily be driven downwards for removal with a suitable stepped

drift and new ones inserted the same way, preferably with a copper washer

protecting the top surface of the guide. Better practice of course would be to

use a simply made threaded ‘puller’. With the new guides in place, it is useful

to check that a clean valve slides freely but without any play. If the valve is

tight, careful use of an expanding reamer will soon ensure a good sliding fit.

Incidentally, the guides should be positioned so that the top surface projects

3/32” into the valve port.

The

old ones can easily be driven downwards for removal with a suitable stepped

drift and new ones inserted the same way, preferably with a copper washer

protecting the top surface of the guide. Better practice of course would be to

use a simply made threaded ‘puller’. With the new guides in place, it is useful

to check that a clean valve slides freely but without any play. If the valve is

tight, careful use of an expanding reamer will soon ensure a good sliding fit.

Incidentally, the guides should be positioned so that the top surface projects

3/32” into the valve port.  This can with advantage be cut at 30 and only a narrow seat of say 1/16” width

is needed, because the incoming mixture tends to keep the valve and seat a good

deal cooler than the exhaust.

This can with advantage be cut at 30 and only a narrow seat of say 1/16” width

is needed, because the incoming mixture tends to keep the valve and seat a good

deal cooler than the exhaust.