KNOW YOUR OIL PRESSURE

READINGS

The Austin Seven has a splash fed lubrication system,

i.e. The big ends are fed oil through oil squirting through 2 jets and catching

the lubricant as the crank-shaft rotates. This set up is fairly unique to the

Seven.

When the engine is cold the needle flies off the end of

the gauge, which is quite normal. However, when the engine is good and hot, the

needle should read within the parameters of the gauge, even reading next to

nothing when ticking over.

If it should ever rise u nexpectedly

above “normal” readings when drivoing along, you may well have a blocked oil

jet. You must stop and sort it, otherwise you run the risk of overheating a

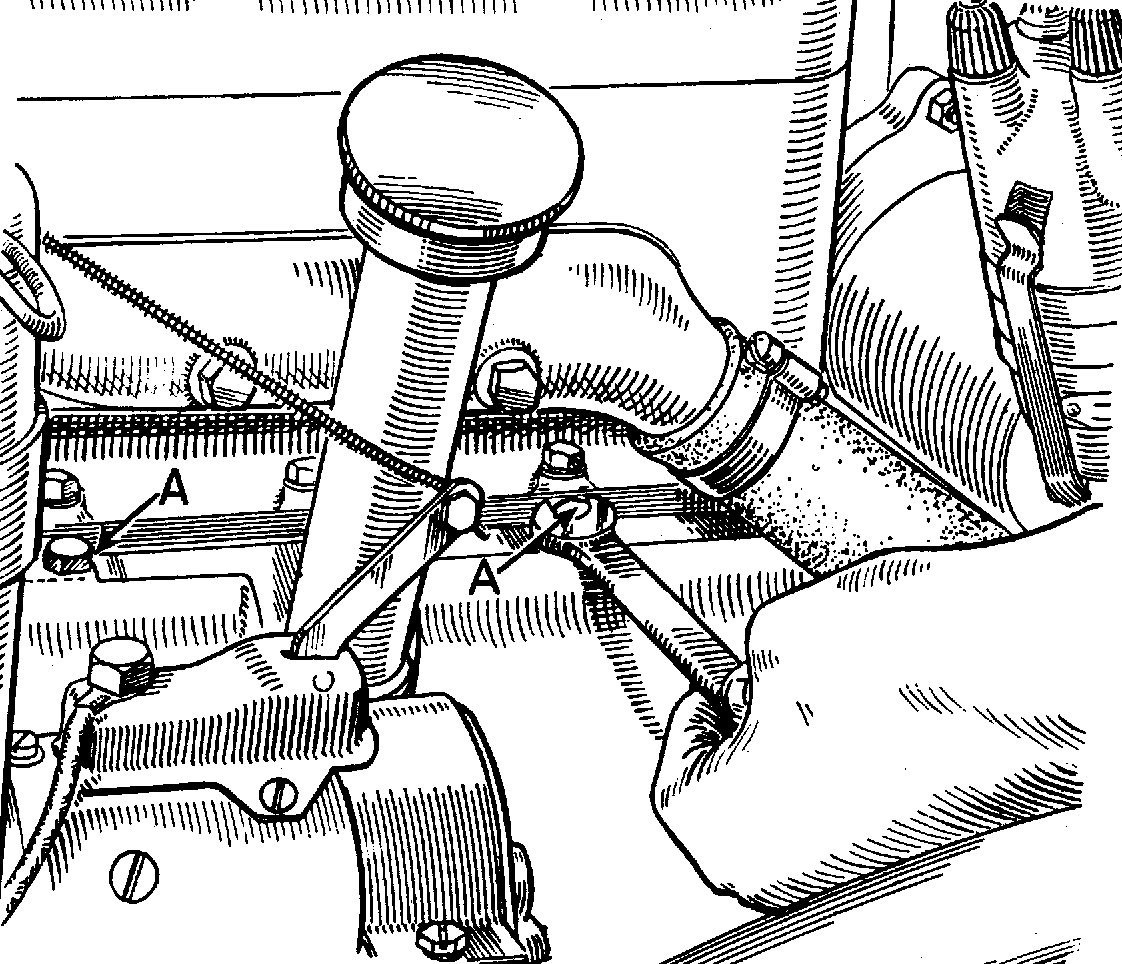

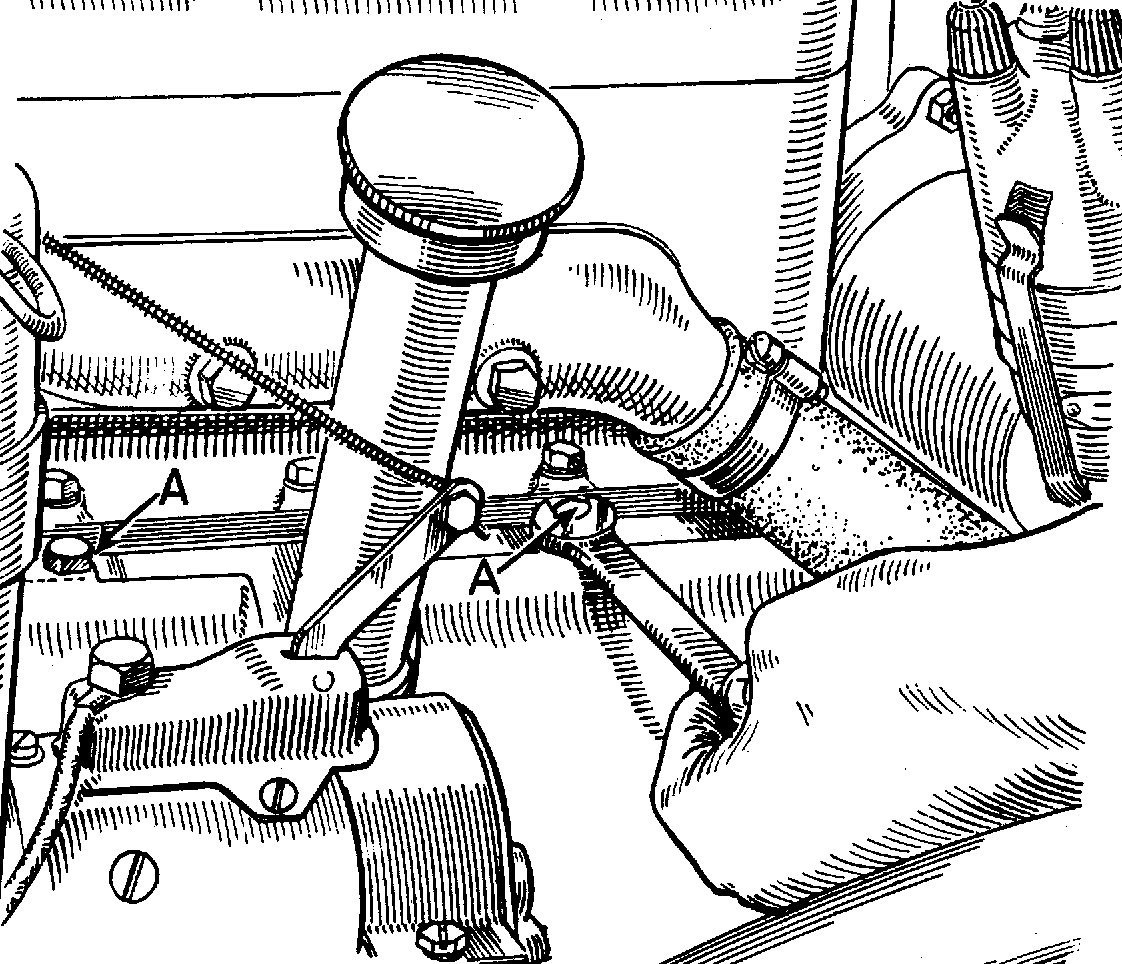

starved bigend bearing with expensive results. Observing the diagram, the oil

jets are marked “A” on the off-side of the engine. Remove the two small jet

bolts. They are under the side water manifold along the top of the ally

crankcase. If you have a forward facing starter motor, it is advisable to

disconnect the battery, so you don't short your spanner on the terminal. You

will need a stiff piece of wire about 1/16 inch diameter about 7 inches long.

(always worth keeping under the seat). Fiddly and awkward, you need to push the

wire down past the gallery into the top of the jet and then on down about 2

inches, (patience and persistence is needed to locate the hole). This will

ensure the jet hole is clear. Repeat on the other one and reassemble, noting the

fibre washer under each bolt head. Do not overtighten the bolts.

nexpectedly

above “normal” readings when drivoing along, you may well have a blocked oil

jet. You must stop and sort it, otherwise you run the risk of overheating a

starved bigend bearing with expensive results. Observing the diagram, the oil

jets are marked “A” on the off-side of the engine. Remove the two small jet

bolts. They are under the side water manifold along the top of the ally

crankcase. If you have a forward facing starter motor, it is advisable to

disconnect the battery, so you don't short your spanner on the terminal. You

will need a stiff piece of wire about 1/16 inch diameter about 7 inches long.

(always worth keeping under the seat). Fiddly and awkward, you need to push the

wire down past the gallery into the top of the jet and then on down about 2

inches, (patience and persistence is needed to locate the hole). This will

ensure the jet hole is clear. Repeat on the other one and reassemble, noting the

fibre washer under each bolt head. Do not overtighten the bolts.

Start her up and check for leaks and hopefully oil

pressure will be back down to normal. It might be worth doing a dummy run of the

procedure in the warmth of your garage to get the hang of locating the jet hole.

Don’t panic, in all the thousands of miles I have covered in a variety of Sevens

it has only happened twice and, yes, I did run a big end! Make sure you change

your oil regularly and do not use high detergent lubricants . Gary Munn

(GM Seven Services)

Also see an excellent hint on poking through the jets.

Click here.

nexpectedly

above “normal” readings when drivoing along, you may well have a blocked oil

jet. You must stop and sort it, otherwise you run the risk of overheating a

starved bigend bearing with expensive results. Observing the diagram, the oil

jets are marked “A” on the off-side of the engine. Remove the two small jet

bolts. They are under the side water manifold along the top of the ally

crankcase. If you have a forward facing starter motor, it is advisable to

disconnect the battery, so you don't short your spanner on the terminal. You

will need a stiff piece of wire about 1/16 inch diameter about 7 inches long.

(always worth keeping under the seat). Fiddly and awkward, you need to push the

wire down past the gallery into the top of the jet and then on down about 2

inches, (patience and persistence is needed to locate the hole). This will

ensure the jet hole is clear. Repeat on the other one and reassemble, noting the

fibre washer under each bolt head. Do not overtighten the bolts.

nexpectedly

above “normal” readings when drivoing along, you may well have a blocked oil

jet. You must stop and sort it, otherwise you run the risk of overheating a

starved bigend bearing with expensive results. Observing the diagram, the oil

jets are marked “A” on the off-side of the engine. Remove the two small jet

bolts. They are under the side water manifold along the top of the ally

crankcase. If you have a forward facing starter motor, it is advisable to

disconnect the battery, so you don't short your spanner on the terminal. You

will need a stiff piece of wire about 1/16 inch diameter about 7 inches long.

(always worth keeping under the seat). Fiddly and awkward, you need to push the

wire down past the gallery into the top of the jet and then on down about 2

inches, (patience and persistence is needed to locate the hole). This will

ensure the jet hole is clear. Repeat on the other one and reassemble, noting the

fibre washer under each bolt head. Do not overtighten the bolts.