OIL JET CLEANING GUIDE

(Reproduced with permission of the Essex Austin Seven Club)

One of the requirements during your Austin Seven service is to clean the oil jets. Access to these is at the top of the crankcase below the side water outlet. Unscrewing the two 1/4in BSF plug bolts allows you to poke a piece of wire through the jet to clear any crud. Most important, as these jets direct oil into the channels on the crankshaft and supply the big end bearings. This is a simple job – sometimes.

An excessively high oil pressure is

a possible symptom of a blocked jet and as this might occur on the road, you

need to do this job in situ. I had to do my jets on the Eurotour last year and

also help someone else to check theirs. It was the devil of a job, especially

the front jet as there’s not much room under the water outlet. You bend the wire

to get in the gap and then blindly feel across the oil gallery for this tiny

hole.

Back home I read somewhere about a

guide to make the job easie r. I don’t know why I hadn’t thought of it before.

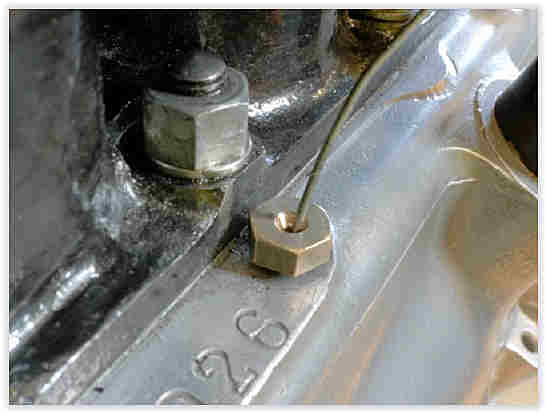

All you need is a 1/4in BSF bolt, 3/4in long, and a lathe. With the thread in

the chuck, start a pilot hole in the bolt head with a centre point bit and drill

deep enough to give you a nice countersink start. I then drilled all the way

through with a 1.5mm bit as this suited my jet size and wire.

r. I don’t know why I hadn’t thought of it before.

All you need is a 1/4in BSF bolt, 3/4in long, and a lathe. With the thread in

the chuck, start a pilot hole in the bolt head with a centre point bit and drill

deep enough to give you a nice countersink start. I then drilled all the way

through with a 1.5mm bit as this suited my jet size and wire.

Incidentally, the jets on the three bearing engine are smaller in diameter than the two bearing in order to increase pressure to the centre main bearing. There is plenty of discussion on the A7 Friends forum about the correct sizes. Next I ran a die down the thread, tightened in the die holder to very slightly undercut the thread. This allows you to easily screw in with your fingers.

Operation is simple – remove your

oil jet plug bolt, screw in your guide bolt until it just lightly contacts the

top of the jet, and poke your wire through. First time, every time!

Peter Lawson EA7C with many thanks.