BRAKING EFFICIENCY (PART 2)

Click Here For

Part 1

(from

the Austin Magazine 1936)

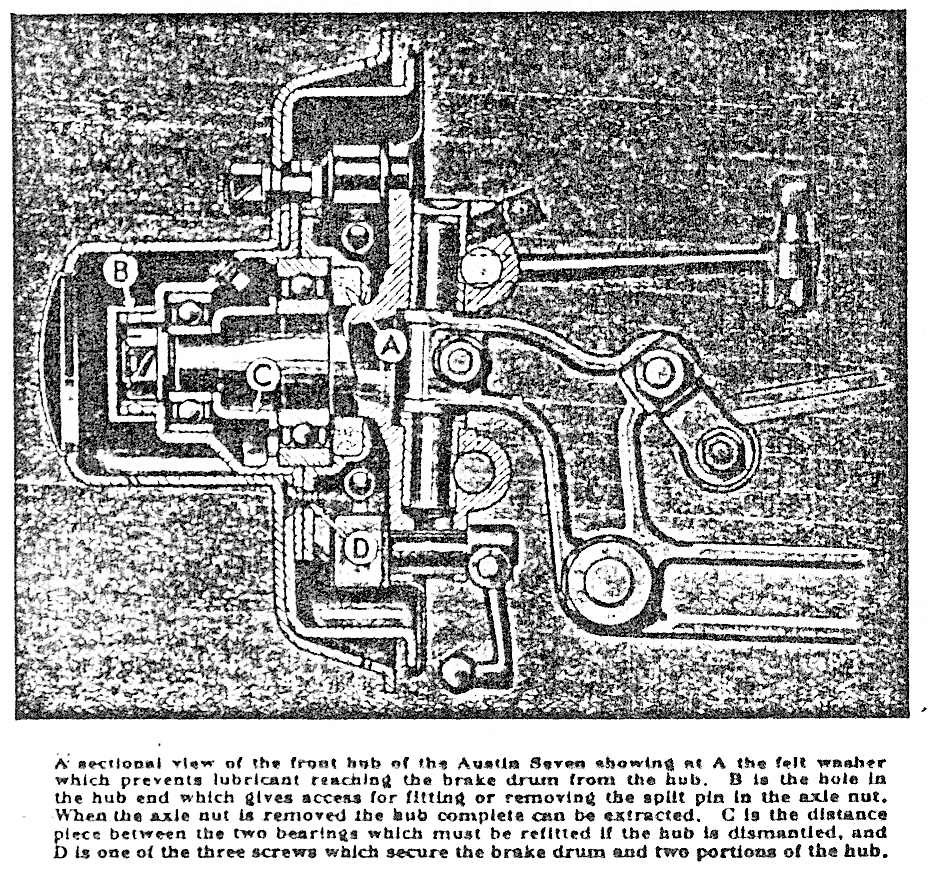

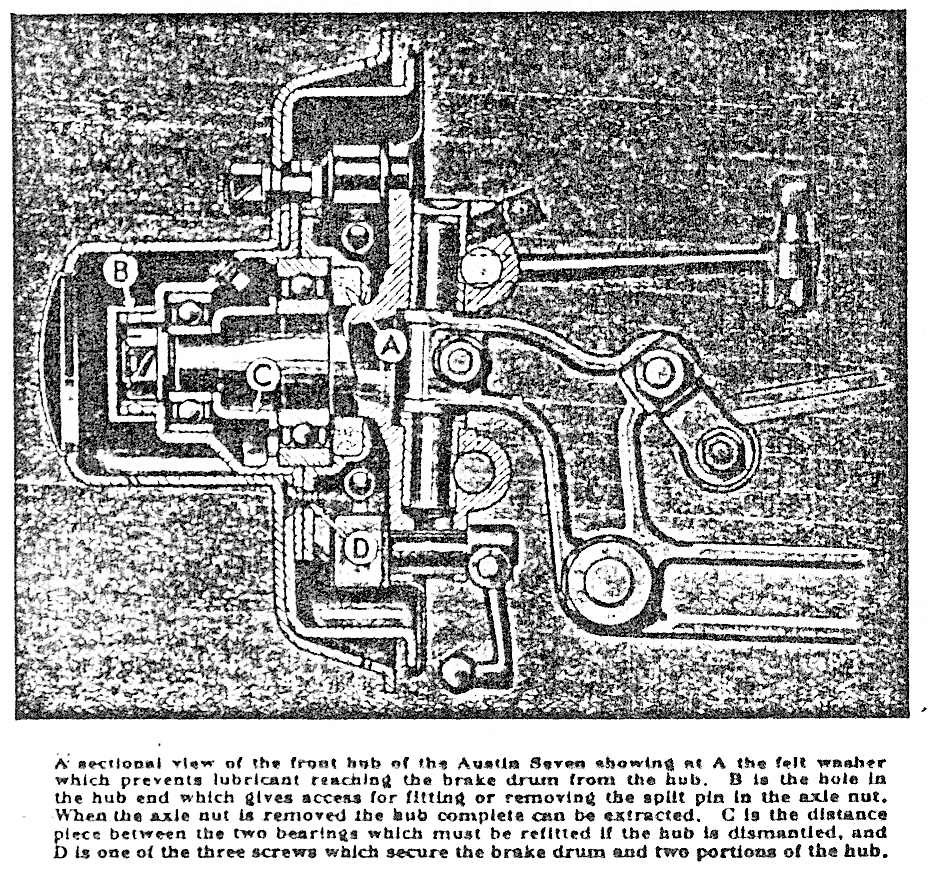

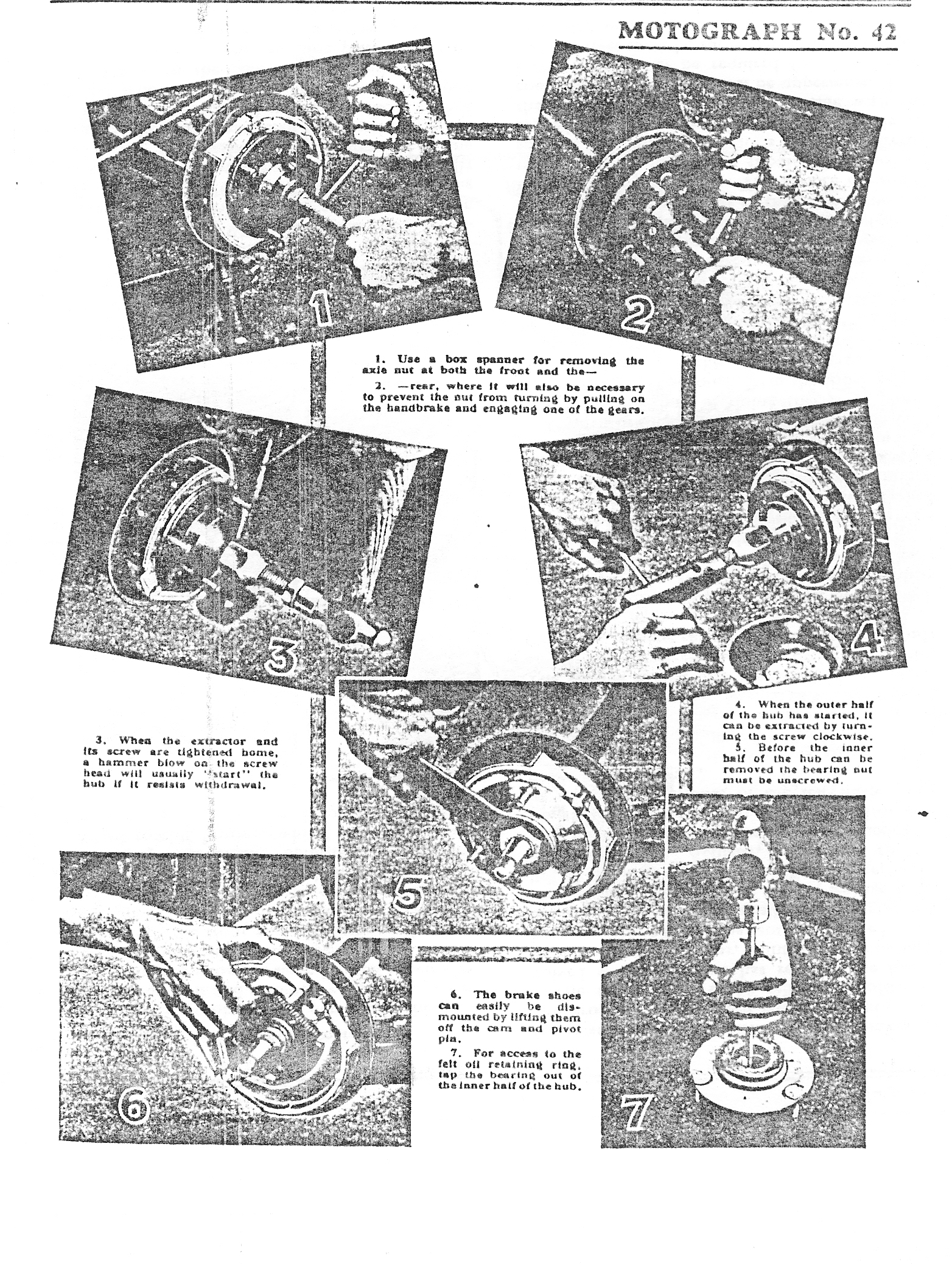

IN our last issue we dealt with Austin Seven brake

adjustments and with maintenance as far as proves possible without removing the

hubs. Here we propose to take

the

subject of brake attentions on this model a step further and deal with the

rectification and prevention of "oil on the brakes," as well as the process of

relining, for both of which hub removal is essential. Access to the hubs of

either the front or rear wheels first of all entails removal of the wheel itself

and then the brake drum, the latter being secured to the hub by three screws

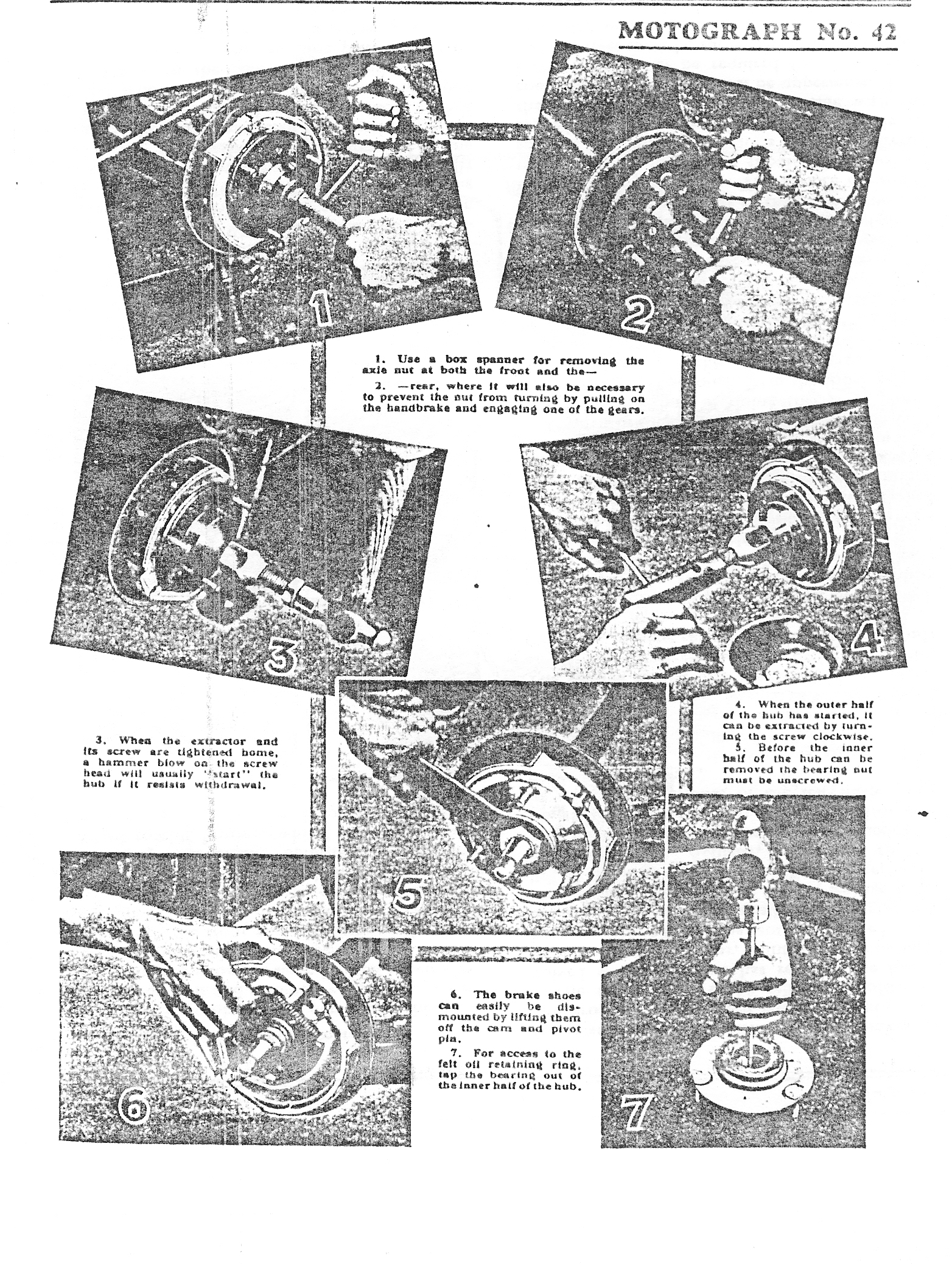

which also hold the two portions of the hub together. For withdrawing the hub a

small extractor is supplied in the tool kit. The front hubs are free for removal

when the axle nut and its securing split pin are removed. The nut will be found

behind the hub cap and will require a 7/16 in. box spanner which will fit inside

the hub casing. The split pin may be found somewhat difficult to deal with as it

is located inside the end of the hub. The head and ends of the pin should first

be chiselled off with a small cold chisel or sheared off by driving the box

spanner onto the nut. Then, using a suitable drift through the hole in the end

of the hub (which should be turned until in line with the split pin) the remains

of the pin can be driven clear of both the nut and the axle end. When the nut is

off it may be possible to prise the hub off the stub axle, but if the hub

extractor is required, its body can be screwed home on the thread of the outside

of the hub and its screw tightened firmly on to the axle end. By continuing to

tighten up this screw, the hub will be withdrawn from the axle. If it proves

stubborn, a smart blow with a hammer on the head of the extractor screw when

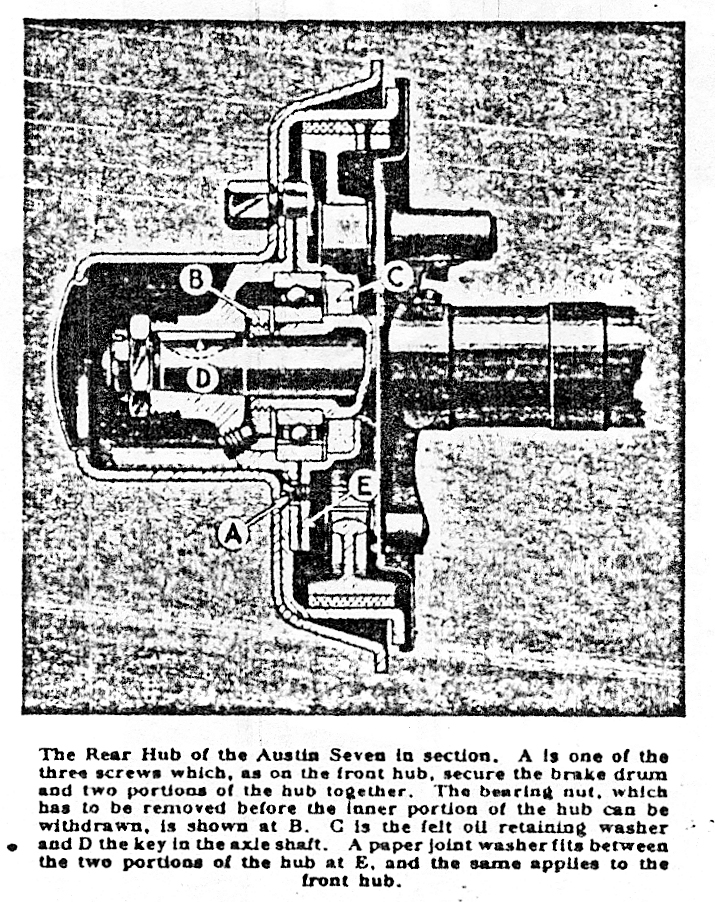

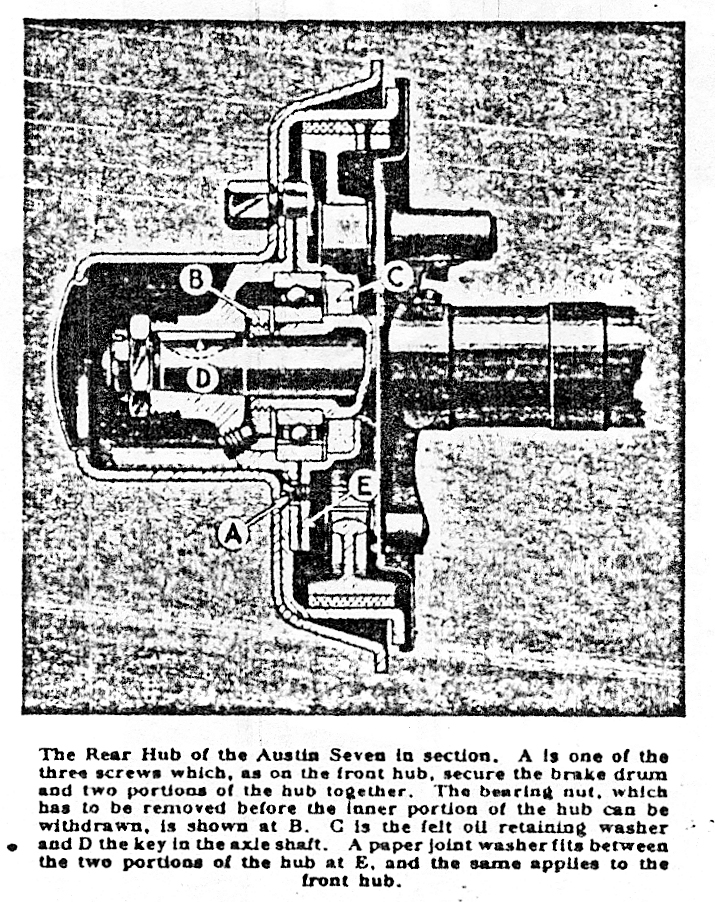

tight will usually "start" it. The procedure for removing the rear hubs is

somewhat different, due to the inner portion of the hub retained by a bearing

nut. When the axle-nut has been removed and the extractor screwed into position,

the outer portion of the hub is first withdrawn. As it is mounted on a taper on

the axle shaft and is keyed to the shaft as well, it may prove more difficult to

withdraw than the front hub, and the practice of tightening both the body of the

extractor and the screw well home, and then giving the head of the latter a

sharp blow to start the hub, will most likely prove essential. Do not mislay the

key; it will be found in the axle-shaft when the hub is clear. The paper washer

located between the two portions of the hub should also be saved unless damaged

so that a renewal is desirable. The large nut which retains the wheel bearing

and inner portion of the hub is now accessible, and can be screwed off the end

of the axle casing when the tab of its locking washer has been bent back.

Subsequently the inner portion of the hub and its bearing can be prised off the

axle casing; if it proves stubborn the outer hub should be refitted up to it and

secured by its screws, whereupon the extractor can again be used to withdraw

both. portions of the hub together. In both the front and rear hubs of the Seven

the oil or grease is prevented from penetrating from the hub to the brake drum

and shoes by a felt washer

the

subject of brake attentions on this model a step further and deal with the

rectification and prevention of "oil on the brakes," as well as the process of

relining, for both of which hub removal is essential. Access to the hubs of

either the front or rear wheels first of all entails removal of the wheel itself

and then the brake drum, the latter being secured to the hub by three screws

which also hold the two portions of the hub together. For withdrawing the hub a

small extractor is supplied in the tool kit. The front hubs are free for removal

when the axle nut and its securing split pin are removed. The nut will be found

behind the hub cap and will require a 7/16 in. box spanner which will fit inside

the hub casing. The split pin may be found somewhat difficult to deal with as it

is located inside the end of the hub. The head and ends of the pin should first

be chiselled off with a small cold chisel or sheared off by driving the box

spanner onto the nut. Then, using a suitable drift through the hole in the end

of the hub (which should be turned until in line with the split pin) the remains

of the pin can be driven clear of both the nut and the axle end. When the nut is

off it may be possible to prise the hub off the stub axle, but if the hub

extractor is required, its body can be screwed home on the thread of the outside

of the hub and its screw tightened firmly on to the axle end. By continuing to

tighten up this screw, the hub will be withdrawn from the axle. If it proves

stubborn, a smart blow with a hammer on the head of the extractor screw when

tight will usually "start" it. The procedure for removing the rear hubs is

somewhat different, due to the inner portion of the hub retained by a bearing

nut. When the axle-nut has been removed and the extractor screwed into position,

the outer portion of the hub is first withdrawn. As it is mounted on a taper on

the axle shaft and is keyed to the shaft as well, it may prove more difficult to

withdraw than the front hub, and the practice of tightening both the body of the

extractor and the screw well home, and then giving the head of the latter a

sharp blow to start the hub, will most likely prove essential. Do not mislay the

key; it will be found in the axle-shaft when the hub is clear. The paper washer

located between the two portions of the hub should also be saved unless damaged

so that a renewal is desirable. The large nut which retains the wheel bearing

and inner portion of the hub is now accessible, and can be screwed off the end

of the axle casing when the tab of its locking washer has been bent back.

Subsequently the inner portion of the hub and its bearing can be prised off the

axle casing; if it proves stubborn the outer hub should be refitted up to it and

secured by its screws, whereupon the extractor can again be used to withdraw

both. portions of the hub together. In both the front and rear hubs of the Seven

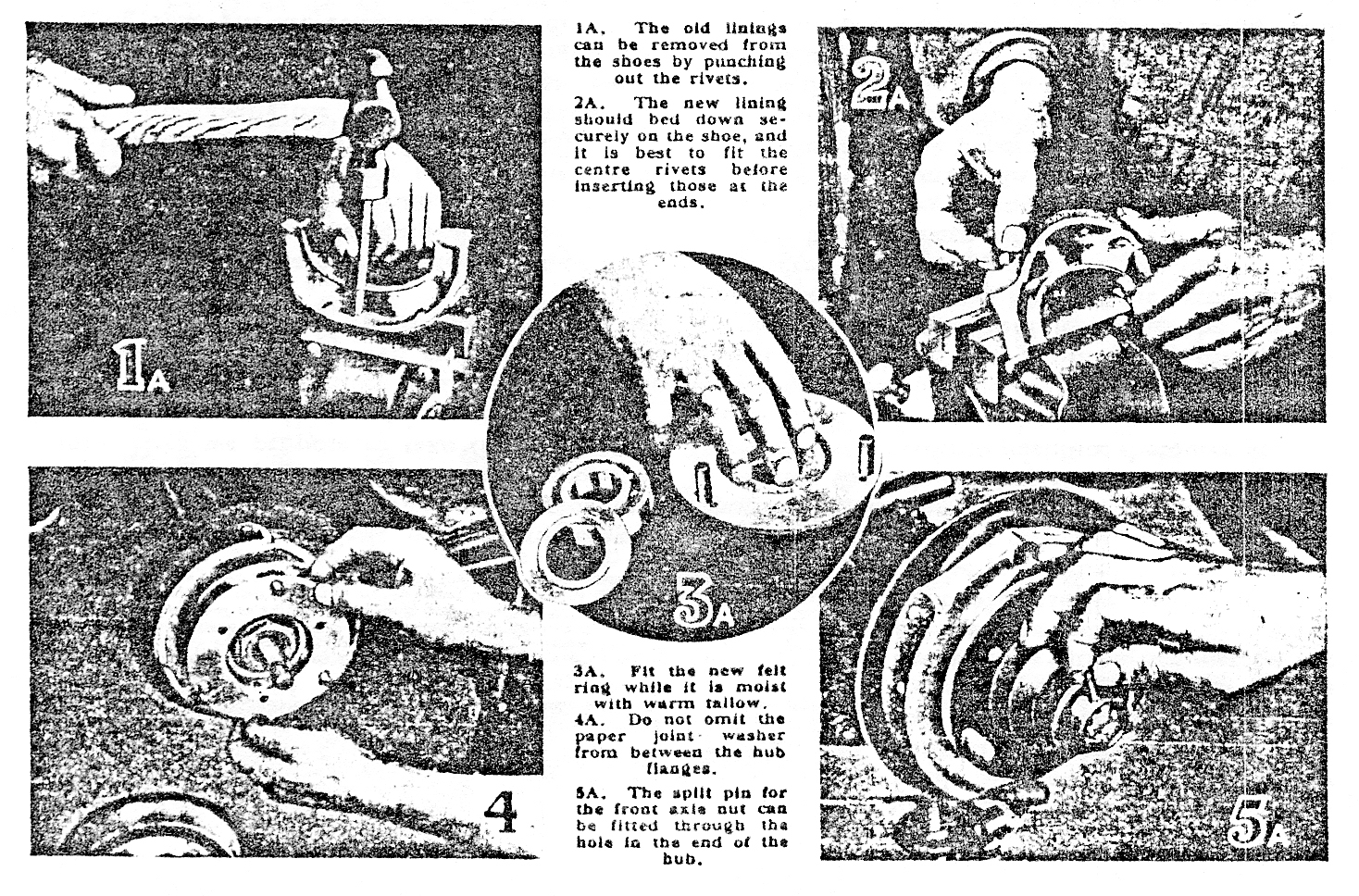

the oil or grease is prevented from penetrating from the hub to the brake drum

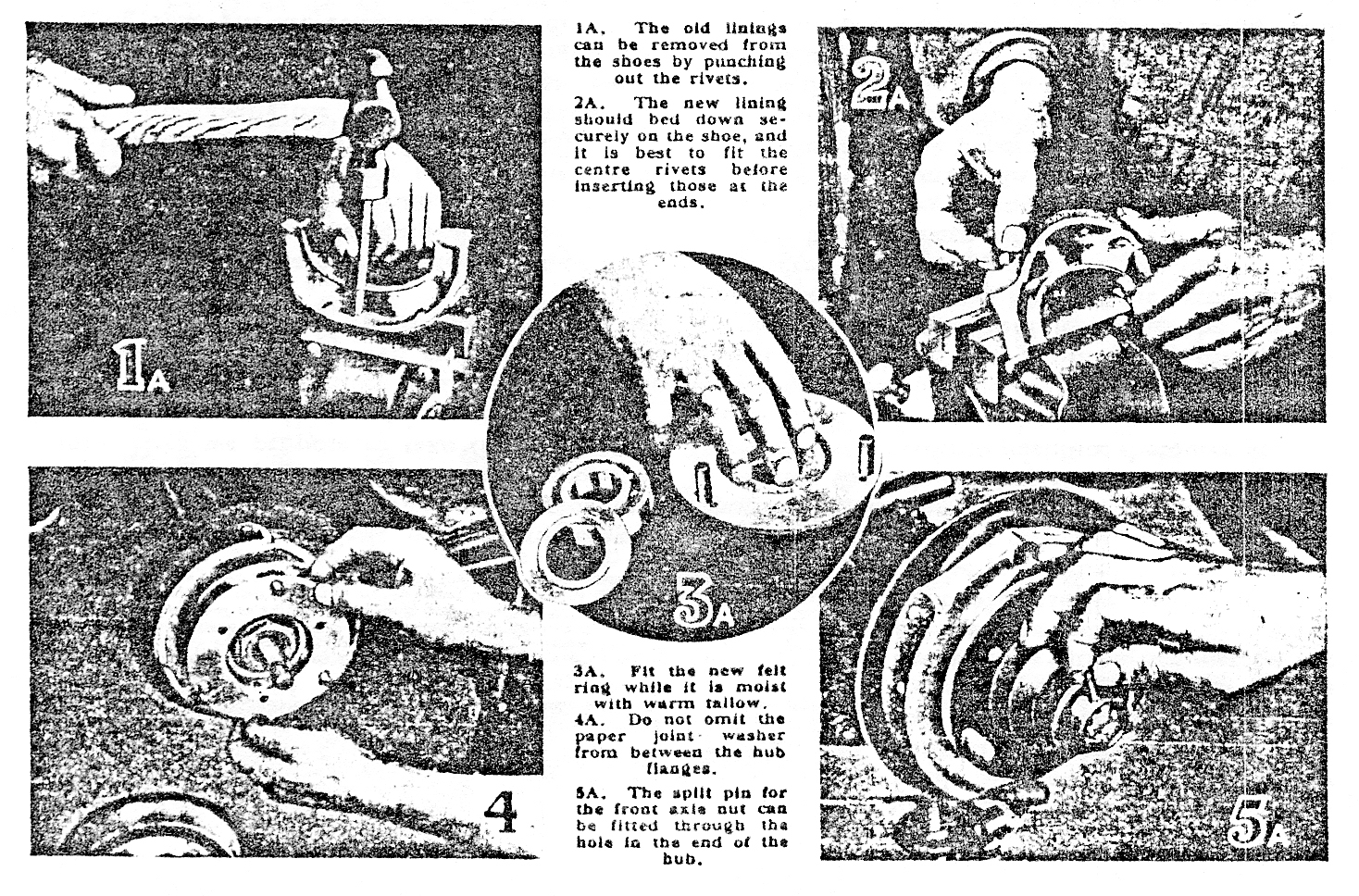

and shoes by a felt washer located behind the ball bearing in the inner hub shell. Splitting the hub gives

access to this bearing, which must be removed from the inner hub casing before

the felt washer can be reached. When the inner hub is dismounted the bearing

can be tapped clear from the rear side. With it will come the retaining plate

for the felt washer, to leave the latter fully exposed. The washer is in the

form of a ring and can be readily extracted from its housing. The new washer

should be soaked in hot liquid tallow and fitted while warm and moist so that

when the tallow sets it will make an effective oil seal. The retaining plate

should be immediately pushed into position with its concave face outwards and

the bearing tapped home to bed on it. When reassembled there should be no

recurrence of oil leakage unless or until the hub (or possibly the axle where

the rear brakes are concerned) is overcharged with lubricant. The question of

brake re-lining is often involved when lubricant has reached the linings as,

quite apart from wear, relining may be required because oil has permanently

impaired their braking efficiency. Naturally, an attempt will first be made to

overcome the oil leakage if the linings are still capable of further service if

protected from oil. Actually, leakage past the felt hub washer may terminate

with a reduction of the supply of lubricant to the hubs and/or axle, in which

case renewal of the felt washer may prove unnecessary. As mentioned in the

previous article, all oil inside the brake drum, on the back plate of the brake

or on the exterior surfaces of the shoes and hub, should be washed off with

petrol. The linings should also be washed with petrol and if they fail to give

efficient braking after this treatment relining can be assumed to be the only

remedy. The need for relining as a result of wear will be obvious from an

examination of the linings which, in this event, will be so thin as to leave no

clearance above the rivet heads. The shoes are held in position on the axle by

the brake springs and can be readily detached when the hub is off. They should

be identified so that the same pairs can be re-assembled together after the

re-lining process. Removal of the old linings presents no difficulty. The

easiest method of doing this is to punch the hollow rivets through from the

inner face of the shoe holding it the while in a vice. If the rivets are not of

the hollow type their heads can be cut off with a cold chisel so that the rest

of the rivet can be punched clear. Alternatively, the old linings can be prised

off the shoes and the rivets removed subsequently. The shoes, although of

aluminium, are fairly substantial, but even so it is advisable to avoid being

too vigorous at any stage of the process so that there is no risk of damage or

distortion. The surface on which the new lining has to bed should be cleaned off

so that the lining, which is supplied already curved to the correct radius, can

sit securely on the shoe. Needless to say, the side with the countersunk rivet

holes will be uppermost. Four hollow rivets will be required for each lining,

and the rivet must be supported on a punch held in a vice while its head is

riveted over. The two centre ones should be fitted first and riveted well home

so that their heads bed down into the countersinking in the lining. Then the end

rivets can be fitted to make the lining secure with all the rivet heads well

countersunk. Each shoe can be similarly treated and it is essential to reline at

the one time all four shoes on the one axle. Actually, of course, it is

desirable to reline all four brakes, both front and rear, when undertaking this

attention, but if for any reason only one axle is dealt with, it will obviously

be necessary to re-compensate the operation of the brakes as between the two

axles. With the lining fitted, it should be "backed off" at each extremity, i.e.

tapered down to half thickness,

located behind the ball bearing in the inner hub shell. Splitting the hub gives

access to this bearing, which must be removed from the inner hub casing before

the felt washer can be reached. When the inner hub is dismounted the bearing

can be tapped clear from the rear side. With it will come the retaining plate

for the felt washer, to leave the latter fully exposed. The washer is in the

form of a ring and can be readily extracted from its housing. The new washer

should be soaked in hot liquid tallow and fitted while warm and moist so that

when the tallow sets it will make an effective oil seal. The retaining plate

should be immediately pushed into position with its concave face outwards and

the bearing tapped home to bed on it. When reassembled there should be no

recurrence of oil leakage unless or until the hub (or possibly the axle where

the rear brakes are concerned) is overcharged with lubricant. The question of

brake re-lining is often involved when lubricant has reached the linings as,

quite apart from wear, relining may be required because oil has permanently

impaired their braking efficiency. Naturally, an attempt will first be made to

overcome the oil leakage if the linings are still capable of further service if

protected from oil. Actually, leakage past the felt hub washer may terminate

with a reduction of the supply of lubricant to the hubs and/or axle, in which

case renewal of the felt washer may prove unnecessary. As mentioned in the

previous article, all oil inside the brake drum, on the back plate of the brake

or on the exterior surfaces of the shoes and hub, should be washed off with

petrol. The linings should also be washed with petrol and if they fail to give

efficient braking after this treatment relining can be assumed to be the only

remedy. The need for relining as a result of wear will be obvious from an

examination of the linings which, in this event, will be so thin as to leave no

clearance above the rivet heads. The shoes are held in position on the axle by

the brake springs and can be readily detached when the hub is off. They should

be identified so that the same pairs can be re-assembled together after the

re-lining process. Removal of the old linings presents no difficulty. The

easiest method of doing this is to punch the hollow rivets through from the

inner face of the shoe holding it the while in a vice. If the rivets are not of

the hollow type their heads can be cut off with a cold chisel so that the rest

of the rivet can be punched clear. Alternatively, the old linings can be prised

off the shoes and the rivets removed subsequently. The shoes, although of

aluminium, are fairly substantial, but even so it is advisable to avoid being

too vigorous at any stage of the process so that there is no risk of damage or

distortion. The surface on which the new lining has to bed should be cleaned off

so that the lining, which is supplied already curved to the correct radius, can

sit securely on the shoe. Needless to say, the side with the countersunk rivet

holes will be uppermost. Four hollow rivets will be required for each lining,

and the rivet must be supported on a punch held in a vice while its head is

riveted over. The two centre ones should be fitted first and riveted well home

so that their heads bed down into the countersinking in the lining. Then the end

rivets can be fitted to make the lining secure with all the rivet heads well

countersunk. Each shoe can be similarly treated and it is essential to reline at

the one time all four shoes on the one axle. Actually, of course, it is

desirable to reline all four brakes, both front and rear, when undertaking this

attention, but if for any reason only one axle is dealt with, it will obviously

be necessary to re-compensate the operation of the brakes as between the two

axles. With the lining fitted, it should be "backed off" at each extremity, i.e.

tapered down to half thickness, extending

about half-an-inch from the end. This prevents brake "grab" and uneven

operation. The surface of the lining should also be roughened slightly with a

rough file. After re-assembling the shoes in their correct pairs on the axle,

the hubs can be refitted. At the rear it will be necessary to tap the inner hub

with wheel bearing, etc., into position on the axle casing so that its securing

nut can be tightened until quite firm and locked with its washer. Then, before

fitting the outer portion of the hub, the bearing should be smeared well with

grease to provide initial lubrication, the key inserted in the end of the axle

shaft, and the paper joint washer (or preferably a new one) fitted to the joint

surface of the inner hub. The outer hub can then be replaced on the axle shaft

and key and driven up approximately into position. The hub can be finally pulled

up into position by the axle nuts, which must be secured by its spilt pin when

home. With the outer portion of the hub located the inner hub shell should be

prised outward if necessary so that the two hub flanges meet with the holes for

the three securing screws in alignment. The front hub, if split, also requires

the paper joint washer (or a new one) to be fitted between the two portions of

the hub, and an initial supply of grease supplied to the bearing, but in this

instance the hub can be assembled before being refitted on the axle. When the

front axle nut has been tightened, its split pin must be fitted, for which one

of the slots in the nut and the hole in the end of the hub must be aligned with

the hole in the stub axle. If relining has been undertaken it will be necessary

to slacken off the brake adjustment before the brake drums can be replaced.

Tighten the three securing screws for each drum evenly, a turn or so at a time.

Finally, before the wheels are fitted, a good charge of grease should be given

through the grease plug on each hub.

extending

about half-an-inch from the end. This prevents brake "grab" and uneven

operation. The surface of the lining should also be roughened slightly with a

rough file. After re-assembling the shoes in their correct pairs on the axle,

the hubs can be refitted. At the rear it will be necessary to tap the inner hub

with wheel bearing, etc., into position on the axle casing so that its securing

nut can be tightened until quite firm and locked with its washer. Then, before

fitting the outer portion of the hub, the bearing should be smeared well with

grease to provide initial lubrication, the key inserted in the end of the axle

shaft, and the paper joint washer (or preferably a new one) fitted to the joint

surface of the inner hub. The outer hub can then be replaced on the axle shaft

and key and driven up approximately into position. The hub can be finally pulled

up into position by the axle nuts, which must be secured by its spilt pin when

home. With the outer portion of the hub located the inner hub shell should be

prised outward if necessary so that the two hub flanges meet with the holes for

the three securing screws in alignment. The front hub, if split, also requires

the paper joint washer (or a new one) to be fitted between the two portions of

the hub, and an initial supply of grease supplied to the bearing, but in this

instance the hub can be assembled before being refitted on the axle. When the

front axle nut has been tightened, its split pin must be fitted, for which one

of the slots in the nut and the hole in the end of the hub must be aligned with

the hole in the stub axle. If relining has been undertaken it will be necessary

to slacken off the brake adjustment before the brake drums can be replaced.

Tighten the three securing screws for each drum evenly, a turn or so at a time.

Finally, before the wheels are fitted, a good charge of grease should be given

through the grease plug on each hub.

Click Here

For Part 1

the

subject of brake attentions on this model a step further and deal with the

rectification and prevention of "oil on the brakes," as well as the process of

relining, for both of which hub removal is essential. Access to the hubs of

either the front or rear wheels first of all entails removal of the wheel itself

and then the brake drum, the latter being secured to the hub by three screws

which also hold the two portions of the hub together. For withdrawing the hub a

small extractor is supplied in the tool kit. The front hubs are free for removal

when the axle nut and its securing split pin are removed. The nut will be found

behind the hub cap and will require a 7/16 in. box spanner which will fit inside

the hub casing. The split pin may be found somewhat difficult to deal with as it

is located inside the end of the hub. The head and ends of the pin should first

be chiselled off with a small cold chisel or sheared off by driving the box

spanner onto the nut. Then, using a suitable drift through the hole in the end

of the hub (which should be turned until in line with the split pin) the remains

of the pin can be driven clear of both the nut and the axle end. When the nut is

off it may be possible to prise the hub off the stub axle, but if the hub

extractor is required, its body can be screwed home on the thread of the outside

of the hub and its screw tightened firmly on to the axle end. By continuing to

tighten up this screw, the hub will be withdrawn from the axle. If it proves

stubborn, a smart blow with a hammer on the head of the extractor screw when

tight will usually "start" it. The procedure for removing the rear hubs is

somewhat different, due to the inner portion of the hub retained by a bearing

nut. When the axle-nut has been removed and the extractor screwed into position,

the outer portion of the hub is first withdrawn. As it is mounted on a taper on

the axle shaft and is keyed to the shaft as well, it may prove more difficult to

withdraw than the front hub, and the practice of tightening both the body of the

extractor and the screw well home, and then giving the head of the latter a

sharp blow to start the hub, will most likely prove essential. Do not mislay the

key; it will be found in the axle-shaft when the hub is clear. The paper washer

located between the two portions of the hub should also be saved unless damaged

so that a renewal is desirable. The large nut which retains the wheel bearing

and inner portion of the hub is now accessible, and can be screwed off the end

of the axle casing when the tab of its locking washer has been bent back.

Subsequently the inner portion of the hub and its bearing can be prised off the

axle casing; if it proves stubborn the outer hub should be refitted up to it and

secured by its screws, whereupon the extractor can again be used to withdraw

both. portions of the hub together. In both the front and rear hubs of the Seven

the oil or grease is prevented from penetrating from the hub to the brake drum

and shoes by a felt washer

the

subject of brake attentions on this model a step further and deal with the

rectification and prevention of "oil on the brakes," as well as the process of

relining, for both of which hub removal is essential. Access to the hubs of

either the front or rear wheels first of all entails removal of the wheel itself

and then the brake drum, the latter being secured to the hub by three screws

which also hold the two portions of the hub together. For withdrawing the hub a

small extractor is supplied in the tool kit. The front hubs are free for removal

when the axle nut and its securing split pin are removed. The nut will be found

behind the hub cap and will require a 7/16 in. box spanner which will fit inside

the hub casing. The split pin may be found somewhat difficult to deal with as it

is located inside the end of the hub. The head and ends of the pin should first

be chiselled off with a small cold chisel or sheared off by driving the box

spanner onto the nut. Then, using a suitable drift through the hole in the end

of the hub (which should be turned until in line with the split pin) the remains

of the pin can be driven clear of both the nut and the axle end. When the nut is

off it may be possible to prise the hub off the stub axle, but if the hub

extractor is required, its body can be screwed home on the thread of the outside

of the hub and its screw tightened firmly on to the axle end. By continuing to

tighten up this screw, the hub will be withdrawn from the axle. If it proves

stubborn, a smart blow with a hammer on the head of the extractor screw when

tight will usually "start" it. The procedure for removing the rear hubs is

somewhat different, due to the inner portion of the hub retained by a bearing

nut. When the axle-nut has been removed and the extractor screwed into position,

the outer portion of the hub is first withdrawn. As it is mounted on a taper on

the axle shaft and is keyed to the shaft as well, it may prove more difficult to

withdraw than the front hub, and the practice of tightening both the body of the

extractor and the screw well home, and then giving the head of the latter a

sharp blow to start the hub, will most likely prove essential. Do not mislay the

key; it will be found in the axle-shaft when the hub is clear. The paper washer

located between the two portions of the hub should also be saved unless damaged

so that a renewal is desirable. The large nut which retains the wheel bearing

and inner portion of the hub is now accessible, and can be screwed off the end

of the axle casing when the tab of its locking washer has been bent back.

Subsequently the inner portion of the hub and its bearing can be prised off the

axle casing; if it proves stubborn the outer hub should be refitted up to it and

secured by its screws, whereupon the extractor can again be used to withdraw

both. portions of the hub together. In both the front and rear hubs of the Seven

the oil or grease is prevented from penetrating from the hub to the brake drum

and shoes by a felt washer located behind the ball bearing in the inner hub shell. Splitting the hub gives

access to this bearing, which must be removed from the inner hub casing before

the felt washer can be reached. When the inner hub is dismounted the bearing

can be tapped clear from the rear side. With it will come the retaining plate

for the felt washer, to leave the latter fully exposed. The washer is in the

form of a ring and can be readily extracted from its housing. The new washer

should be soaked in hot liquid tallow and fitted while warm and moist so that

when the tallow sets it will make an effective oil seal. The retaining plate

should be immediately pushed into position with its concave face outwards and

the bearing tapped home to bed on it. When reassembled there should be no

recurrence of oil leakage unless or until the hub (or possibly the axle where

the rear brakes are concerned) is overcharged with lubricant. The question of

brake re-lining is often involved when lubricant has reached the linings as,

quite apart from wear, relining may be required because oil has permanently

impaired their braking efficiency. Naturally, an attempt will first be made to

overcome the oil leakage if the linings are still capable of further service if

protected from oil. Actually, leakage past the felt hub washer may terminate

with a reduction of the supply of lubricant to the hubs and/or axle, in which

case renewal of the felt washer may prove unnecessary. As mentioned in the

previous article, all oil inside the brake drum, on the back plate of the brake

or on the exterior surfaces of the shoes and hub, should be washed off with

petrol. The linings should also be washed with petrol and if they fail to give

efficient braking after this treatment relining can be assumed to be the only

remedy. The need for relining as a result of wear will be obvious from an

examination of the linings which, in this event, will be so thin as to leave no

clearance above the rivet heads. The shoes are held in position on the axle by

the brake springs and can be readily detached when the hub is off. They should

be identified so that the same pairs can be re-assembled together after the

re-lining process. Removal of the old linings presents no difficulty. The

easiest method of doing this is to punch the hollow rivets through from the

inner face of the shoe holding it the while in a vice. If the rivets are not of

the hollow type their heads can be cut off with a cold chisel so that the rest

of the rivet can be punched clear. Alternatively, the old linings can be prised

off the shoes and the rivets removed subsequently. The shoes, although of

aluminium, are fairly substantial, but even so it is advisable to avoid being

too vigorous at any stage of the process so that there is no risk of damage or

distortion. The surface on which the new lining has to bed should be cleaned off

so that the lining, which is supplied already curved to the correct radius, can

sit securely on the shoe. Needless to say, the side with the countersunk rivet

holes will be uppermost. Four hollow rivets will be required for each lining,

and the rivet must be supported on a punch held in a vice while its head is

riveted over. The two centre ones should be fitted first and riveted well home

so that their heads bed down into the countersinking in the lining. Then the end

rivets can be fitted to make the lining secure with all the rivet heads well

countersunk. Each shoe can be similarly treated and it is essential to reline at

the one time all four shoes on the one axle. Actually, of course, it is

desirable to reline all four brakes, both front and rear, when undertaking this

attention, but if for any reason only one axle is dealt with, it will obviously

be necessary to re-compensate the operation of the brakes as between the two

axles. With the lining fitted, it should be "backed off" at each extremity, i.e.

tapered down to half thickness,

located behind the ball bearing in the inner hub shell. Splitting the hub gives

access to this bearing, which must be removed from the inner hub casing before

the felt washer can be reached. When the inner hub is dismounted the bearing

can be tapped clear from the rear side. With it will come the retaining plate

for the felt washer, to leave the latter fully exposed. The washer is in the

form of a ring and can be readily extracted from its housing. The new washer

should be soaked in hot liquid tallow and fitted while warm and moist so that

when the tallow sets it will make an effective oil seal. The retaining plate

should be immediately pushed into position with its concave face outwards and

the bearing tapped home to bed on it. When reassembled there should be no

recurrence of oil leakage unless or until the hub (or possibly the axle where

the rear brakes are concerned) is overcharged with lubricant. The question of

brake re-lining is often involved when lubricant has reached the linings as,

quite apart from wear, relining may be required because oil has permanently

impaired their braking efficiency. Naturally, an attempt will first be made to

overcome the oil leakage if the linings are still capable of further service if

protected from oil. Actually, leakage past the felt hub washer may terminate

with a reduction of the supply of lubricant to the hubs and/or axle, in which

case renewal of the felt washer may prove unnecessary. As mentioned in the

previous article, all oil inside the brake drum, on the back plate of the brake

or on the exterior surfaces of the shoes and hub, should be washed off with

petrol. The linings should also be washed with petrol and if they fail to give

efficient braking after this treatment relining can be assumed to be the only

remedy. The need for relining as a result of wear will be obvious from an

examination of the linings which, in this event, will be so thin as to leave no

clearance above the rivet heads. The shoes are held in position on the axle by

the brake springs and can be readily detached when the hub is off. They should

be identified so that the same pairs can be re-assembled together after the

re-lining process. Removal of the old linings presents no difficulty. The

easiest method of doing this is to punch the hollow rivets through from the

inner face of the shoe holding it the while in a vice. If the rivets are not of

the hollow type their heads can be cut off with a cold chisel so that the rest

of the rivet can be punched clear. Alternatively, the old linings can be prised

off the shoes and the rivets removed subsequently. The shoes, although of

aluminium, are fairly substantial, but even so it is advisable to avoid being

too vigorous at any stage of the process so that there is no risk of damage or

distortion. The surface on which the new lining has to bed should be cleaned off

so that the lining, which is supplied already curved to the correct radius, can

sit securely on the shoe. Needless to say, the side with the countersunk rivet

holes will be uppermost. Four hollow rivets will be required for each lining,

and the rivet must be supported on a punch held in a vice while its head is

riveted over. The two centre ones should be fitted first and riveted well home

so that their heads bed down into the countersinking in the lining. Then the end

rivets can be fitted to make the lining secure with all the rivet heads well

countersunk. Each shoe can be similarly treated and it is essential to reline at

the one time all four shoes on the one axle. Actually, of course, it is

desirable to reline all four brakes, both front and rear, when undertaking this

attention, but if for any reason only one axle is dealt with, it will obviously

be necessary to re-compensate the operation of the brakes as between the two

axles. With the lining fitted, it should be "backed off" at each extremity, i.e.

tapered down to half thickness, extending

about half-an-inch from the end. This prevents brake "grab" and uneven

operation. The surface of the lining should also be roughened slightly with a

rough file. After re-assembling the shoes in their correct pairs on the axle,

the hubs can be refitted. At the rear it will be necessary to tap the inner hub

with wheel bearing, etc., into position on the axle casing so that its securing

nut can be tightened until quite firm and locked with its washer. Then, before

fitting the outer portion of the hub, the bearing should be smeared well with

grease to provide initial lubrication, the key inserted in the end of the axle

shaft, and the paper joint washer (or preferably a new one) fitted to the joint

surface of the inner hub. The outer hub can then be replaced on the axle shaft

and key and driven up approximately into position. The hub can be finally pulled

up into position by the axle nuts, which must be secured by its spilt pin when

home. With the outer portion of the hub located the inner hub shell should be

prised outward if necessary so that the two hub flanges meet with the holes for

the three securing screws in alignment. The front hub, if split, also requires

the paper joint washer (or a new one) to be fitted between the two portions of

the hub, and an initial supply of grease supplied to the bearing, but in this

instance the hub can be assembled before being refitted on the axle. When the

front axle nut has been tightened, its split pin must be fitted, for which one

of the slots in the nut and the hole in the end of the hub must be aligned with

the hole in the stub axle. If relining has been undertaken it will be necessary

to slacken off the brake adjustment before the brake drums can be replaced.

Tighten the three securing screws for each drum evenly, a turn or so at a time.

Finally, before the wheels are fitted, a good charge of grease should be given

through the grease plug on each hub.

extending

about half-an-inch from the end. This prevents brake "grab" and uneven

operation. The surface of the lining should also be roughened slightly with a

rough file. After re-assembling the shoes in their correct pairs on the axle,

the hubs can be refitted. At the rear it will be necessary to tap the inner hub

with wheel bearing, etc., into position on the axle casing so that its securing

nut can be tightened until quite firm and locked with its washer. Then, before

fitting the outer portion of the hub, the bearing should be smeared well with

grease to provide initial lubrication, the key inserted in the end of the axle

shaft, and the paper joint washer (or preferably a new one) fitted to the joint

surface of the inner hub. The outer hub can then be replaced on the axle shaft

and key and driven up approximately into position. The hub can be finally pulled

up into position by the axle nuts, which must be secured by its spilt pin when

home. With the outer portion of the hub located the inner hub shell should be

prised outward if necessary so that the two hub flanges meet with the holes for

the three securing screws in alignment. The front hub, if split, also requires

the paper joint washer (or a new one) to be fitted between the two portions of

the hub, and an initial supply of grease supplied to the bearing, but in this

instance the hub can be assembled before being refitted on the axle. When the

front axle nut has been tightened, its split pin must be fitted, for which one

of the slots in the nut and the hole in the end of the hub must be aligned with

the hole in the stub axle. If relining has been undertaken it will be necessary

to slacken off the brake adjustment before the brake drums can be replaced.

Tighten the three securing screws for each drum evenly, a turn or so at a time.

Finally, before the wheels are fitted, a good charge of grease should be given

through the grease plug on each hub.