(from the Austin Magazine 1936)

EVERY braking system, however well designed, periodically requires attention if it is to maintain its efficiency, and the braking system on the Austin Seven, although of very simple design, being no exception to this rule, in due course calls for certain adjustments.

These adjustments become necessary

when wear in the friction linings or stretch in the brake linkage results in

excessive free movement of the controls before the brakes begin to operate.

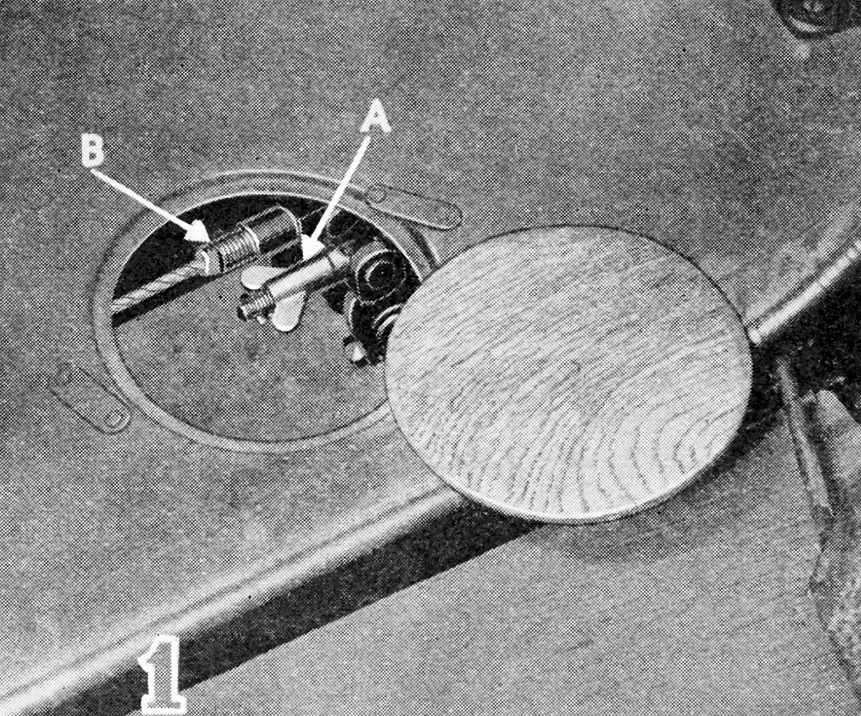

On the Seven, when the brakes are properly adjusted, the free movement before the brake shoes engage the drums should be about one inch at the pedal, and one and a half inches at the top of the hand-brake lever (i.e. one notch on its quadrant). This ensures that the shoes are clear of the drums when released, while giving prompt and complete application of the brakes when running and sufficient grip when the car is parked to hold it on any normal gradient.

When these conditions are satisfied, the Seven should be able to stop in 36 feet or less from 30 m.p.h., without skidding or pulling to either side, on the foot brake being positively applied when travelling on a level road with a good braking surface.

Failure to stop in this distance

can be taken as an indication that the brakes will

benefit from attention, their

application being either late, incomplete or unbalanced, due to the need for

adjustment, or some other rectification.

benefit from attention, their

application being either late, incomplete or unbalanced, due to the need for

adjustment, or some other rectification.

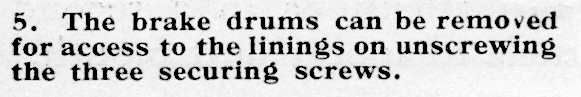

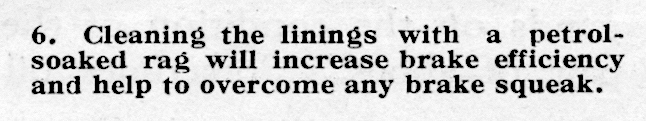

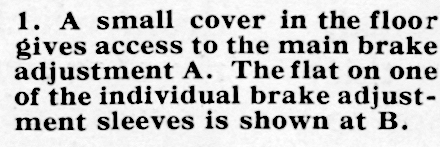

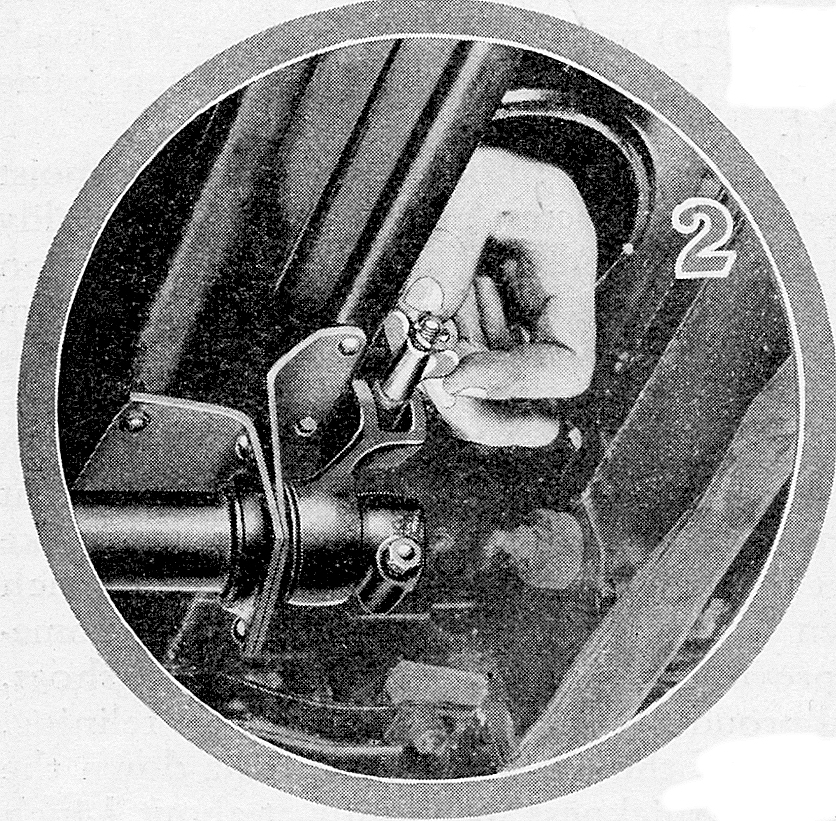

Adjusting the Seven brakes is quite a simple operation. The main adjustment is that which shortens the rod connecting the brake-pedal lever with the cross-shaft. The wing-nut provided for this purpose is reached on present models through a small trap in the floor, just in front of the driving seat, and holding on the hand-brake lever while this adjustment is effected the wing nut will be easier to turn. If, despite this provision, it proves stubborn, due to the presence of rust or mud on the adjustment thread, the latter should be cleaned and penetrating oil applied.

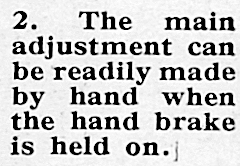

The wing nut must be turned clockwise to take up the free movement until, as already mentioned, only the requisite one inch freedom of the pedal is allowed, to check which, the handbrake must be released. With this main adjustment made, that for the hand-brake can receive attention. Here again the free movement is taken up by a wing nut, in this instance by advancing the cross-shaft lever against which the hand-brake lever operates. This adjustment can only be reached from under the car and if stiff, as it may well be if covered with mud, will require the cleaning and lubricating treatment as suggested for the foot control.

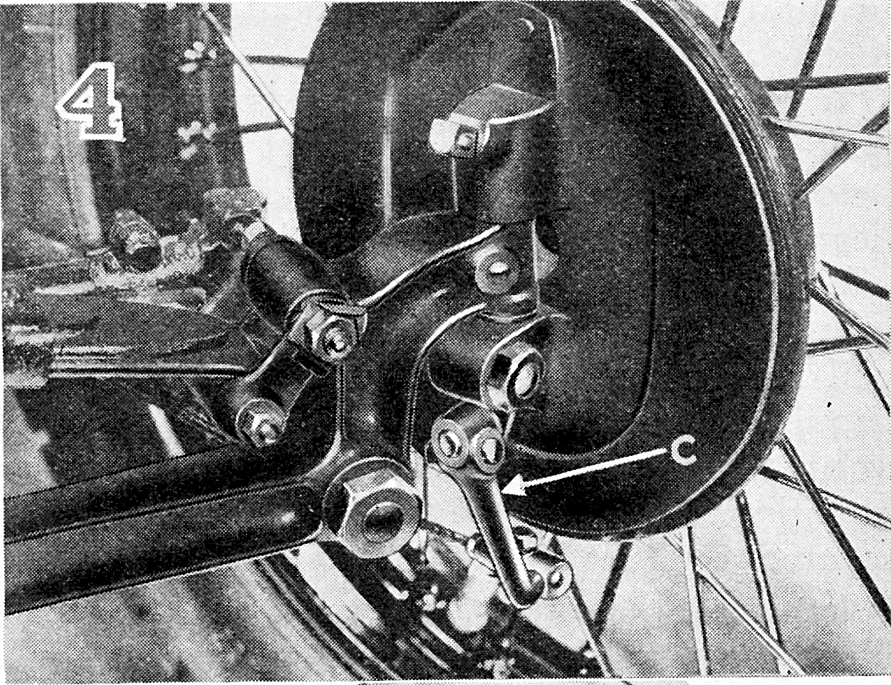

This brings us to another brake

requirement, namely, easy movement of the linkage. Lubrication does not enter

very largely into this matter, as the rear-brake cam levers and the cross-tube

are carried in oil-less zinc bushes which are permanently self-lubricating, and

the front-brake cam levers are lubricated from the swivel axle greaser. But

occasional application of a penetrating oil to these points will do no harm as

it has a cleansing action. Indeed, the presence of mud at important points in

the system may interfere with the brakes, either in their application or their

release, and so it is important that mud deposits should be periodically removed

from around the small cam operating levers on each brake, the cross-tube

bearings, and the compensating sector under the hand-brake lever upon which the

balance of the front brakes relies.

This question of balance is the next consideration to engage our attention. As mentioned in our reference to brake performance, any tendency for the car to pull to one side when the brakes are suddenly applied indicates either variation of the frictional efficiency of the shoes in the drums or, what is more likely, maladjustment of the linkage. Incidentally, balance may be affected, where the front brakes are concerned, by mud preventing the free adjustment of the compensating sector. This can be easily rectified by cleaning this unit and oiling its pivot.

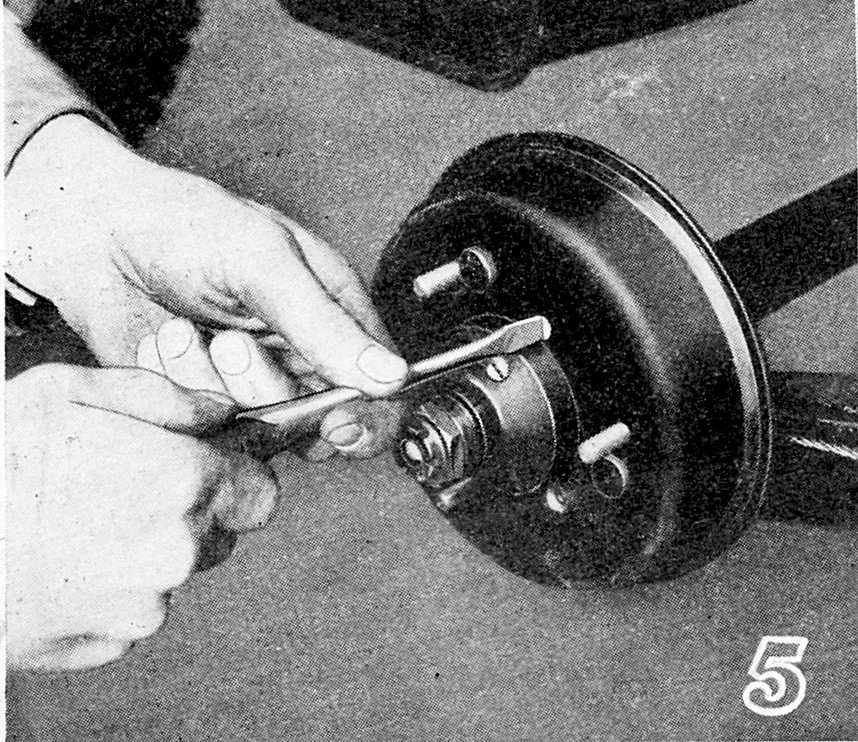

While there is no positive

adjustment for front brake balance, there is an adjustment for each of the rear

brakes. This is provided in the form of a screwed end to each brake rope where

it enters the fork attached to each cross-tube lever. On removing the split-pin

that secures the fork pin, the latter can be withdrawn to release the fork from

the lever so that it can be screwed further on or off the rope end to even up

the braking. The rope end is provided with a small flat so that it can he held

by a spanner for this purpose and it is, of course, important not to twist the

brake rope, which would subsequently unwind and upset the adjustment again on

being refitted.

If, for instance, the car tends to pull to the near-side, or the near-side wheel locks and skids before the others, it can be assumed that the near-side brake is engaging earlier than, or more effectively than the off-side. Unscrewing the near-side fork, or screwing up the off-side fork will reader the braking even. This adjustment should be made half-a-turn of the fork at a time until the desired response results, and subsequently the fork(s) must be quite positively secured by the pin and split pin.

It is usually better to screw up the fork for the "lazy" brake, rather than to relax that for the fierce brake. The reason for this lies in the fact that this adjustment must be considered in relation to the front brakes which, when the car is first assembled, are adjusted to come into operation slightly later than those at the rear. This variation is necessary because in stopping, the momentum of the car transfers much of the load from the rear wheels to the front wheels. When a car in which each axle carries an equal load is stopped in 30 feet from 30 m.p.h., this transfer of weight amounts to as much as 50% i.e., the rear axle has only 25% of the weight of the car while the front axle carries 75%. This decreases road adhesion at the rear and increases it at the front. The difference in the braking application counteracts this effect to give even braking response at both front and rear.

As already mentioned, even braking also depends on the condition of the linings on each pair of shoes. Sometimes oil on the linings, glazing or uneven wear, will reduce the efficiency of one brake as compared with the others. Brake squeak and grab are two other tendencies for which the condition of the linings may be held responsible.

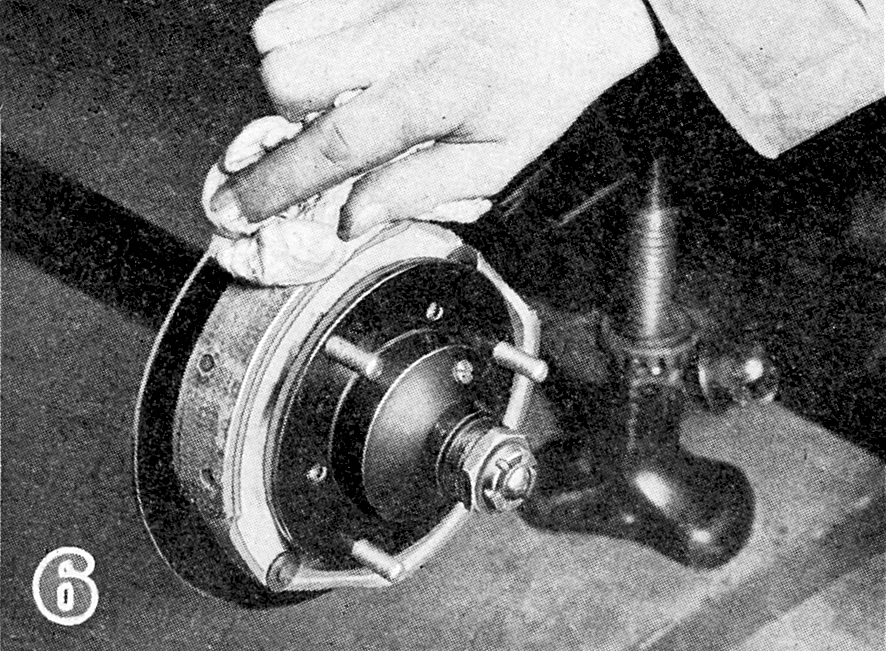

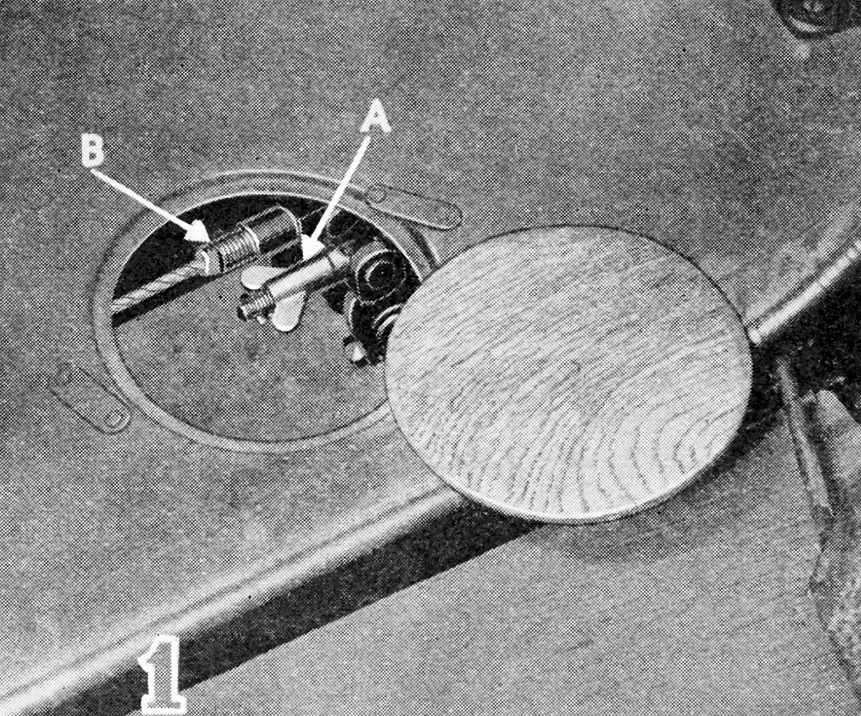

On the Seven the brake linings can be reached quite readily. It is only necessary to jack-up and remove the wheel and the brake-drum can then be dismounted on undoing its three securing screws. While it is desirable to have the handbrake engaged whilst jacking up, it must, of course, be released before the drum can be removed. Therefore, see that one of the wheels of the car is adequately scotched so that there is no chance of the car being pushed off the jack.

Squeak is caused by the presence of

dirt on the linings or in the drum, or bad contact with the drum

which includes

the possibility

of a proud rivet (or rivets) making metallic contact as a result of wear of the

linings, new linings then being required.

which includes

the possibility

of a proud rivet (or rivets) making metallic contact as a result of wear of the

linings, new linings then being required.

For cleaning the linings use a rag

just moist with petrol (or penetrating oil) which will readily pick up the dirt

from the interstices of the friction surfaces. The braking surface inside each

drum should also be dealt with, as dirt sometimes collects on this to give rise

to squeak. If the linings

appear very glazed, slight roughening with a coarse

file or rasp will be of benefit subsequent to cleaning. If a rivet is lying

proud to make contact with the drum it may be possible to punch it down to give

a clearance, although this sometimes proves difficult without removing the

shoes. Several proud rivets indicate the need for relining.

appear very glazed, slight roughening with a coarse

file or rasp will be of benefit subsequent to cleaning. If a rivet is lying

proud to make contact with the drum it may be possible to punch it down to give

a clearance, although this sometimes proves difficult without removing the

shoes. Several proud rivets indicate the need for relining.

Backing-off the linings, i.e. tapering down the ends to half thickness, beginning at about 1/2 inch from the extremities of each can be recoursed to in the unusual event of persistent squeaking or the equally abnormal development of grab, i.e. intermittent fierceness in the brake action.

Lastly, when there appears to be an undue amount of oil on the brakes, the grease-retaining washer which keeps the lubricant in the hubs can be blamed, either due to the hubs having received too much grease or, where the rear brakes are concerned, excessive lubrication of the axle causing oil to find its way to the hubs and past the washer. Reducing the supply of lubricant may then alleviate matters, and, of course, the oil should be washed off the linings, drum, and shoes, with petrol, but usually the only effective remedy is to replace the oil-retaining washers and as this entails dismantling the hubs, which is also required for brake relining, we propose to cover both attentions in a second instalment of this article to appear next month.