The flange to the manifold will probably have distorted. To cure this, file the face first and finish by rubbing on a sheet of emery. The two holes will have closed in - they should have a 5/16 clearance.

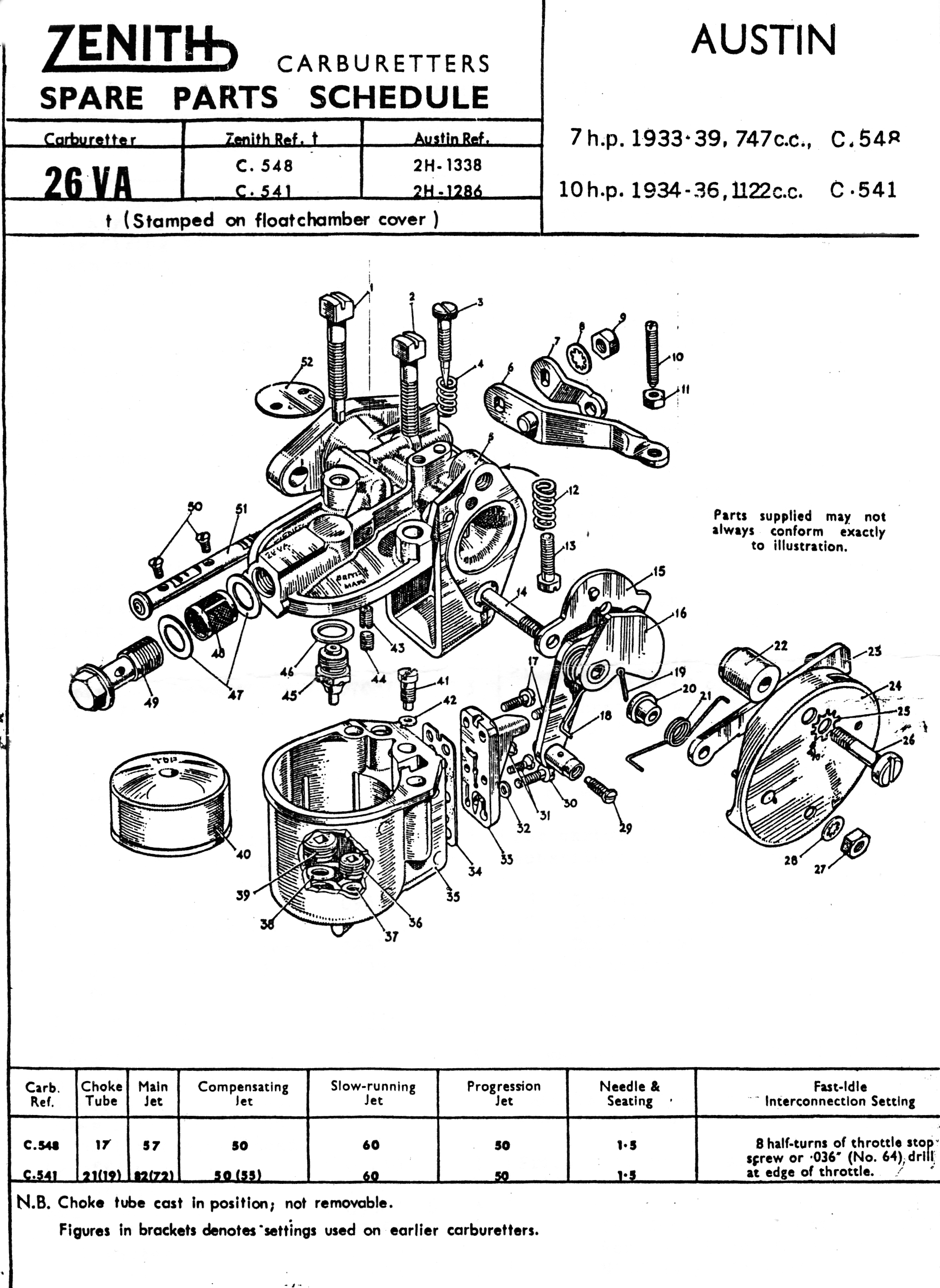

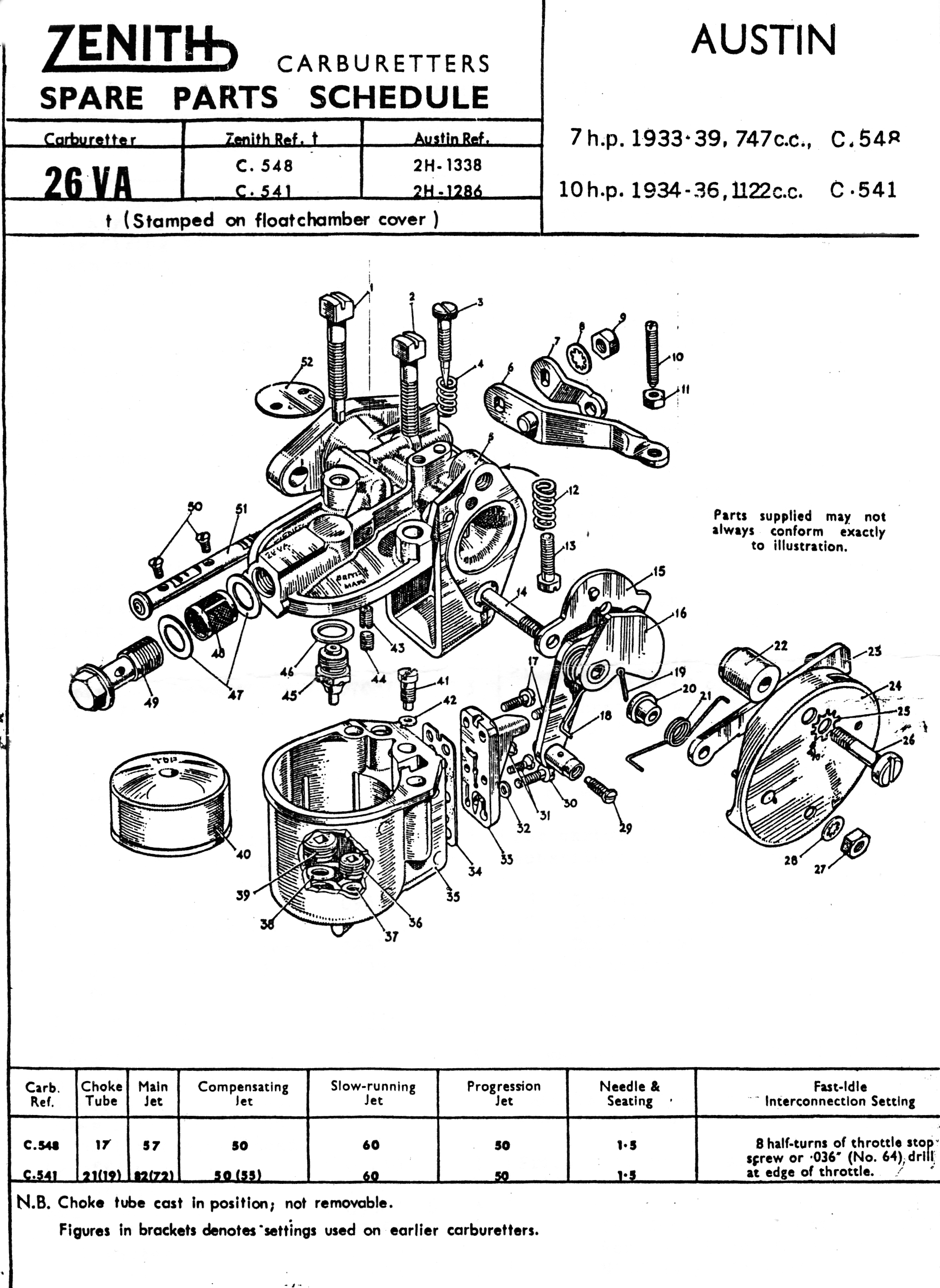

THE ZENITH 26 VA CARBURETTOR

From the Austin Magazine

Strip completely and clean

The flange to the manifold will probably have distorted. To cure this,

file the face first and finish by rubbing on a sheet of emery. The two holes

will have closed in - they should have a 5/16 clearance.

The body (or barrel) must be bored out to take bushes,

for if it is just drilled, it would follow the shape of the distorted, worn

hole.

Make new bushes to suit. They need to have a radius on the inside the same as

the bore in the barrel. Put Loctite on the bushes before pressing them into the

barrel. They must not be too tight a fit or they will break the casting. Ream to

suit new spindle, using a 7mm reamer.

Place butterfly into spindle, leaving screws slack, check that the butterfly is a good fit in the bore, and then tighten screws. This must be a good fit when closed.

Remove emulsion block and jets from bowl. If jets are

very tight you may need a special tool to remove them, and if seized the only

way will be to drill them out. Scrape and lap the top to body to ensure a good

fit. Castings do distort , i.e.could have been run with a loose bowl. Lap

emulsion block on to bowl. Check that all the holes are clear, especially the

one at the top which goes to the slow running jet. Refit emulsion block, using a

new joint and a new aluminium washer on the head of the bottom bolt. On the

body, on the underside of the barrel part, is a blanking-off screw. Remove this

and the progression jet will then be revealedf. It has a screwdriver slot. It

could be tight and care must be taken not to damage it when removing. This jet

allows mixture to bypass the butterfly when it is closed, so that the engine

still runs.

Make sure everything is perfectly clean before preparing to reassemble

REASSEMBLING.

Refit main and compensating jet to bowl. Under these there should be a

small brass insert fitted, (this, in the Zenith schedule, is called a

restriction tube) and a fibre washer.

Refit slow-running jets etc.

Choke parts: Check that the springs are not broken and replace if necessary.

The brass distance piece is fitted between the body and the choke cover, with the small diameter to the body. If otherwise the choke flat will not close properly. After assembly, check that the choke flap is working freely.

Set the screw on the interconnecting lever so that there is clearance at the end. Refit air regulating screw. The spring on this must be strong enough not to be able to be moved without using a screwdriver. Screw it right home until the taper on the end touches it's seating, and then unscrew one and a half turns.

Refit throttle-stop screw. Spring must keep this firm. Adjust it so that it is about to open the throttle. Refit carburetter to engine. Pull choke knob out to full extent. Check that choke flap on carburetter is completely closed.

Get someone to push the throttle pedal down to the floor. Check that throttle on the carburetter is fully open.

Start engine and when warm adjust throttle stop screw and air regulating screw on top of the carburetter. Screwing in makes engine run richer, and screwing out make it run weaker. You can judge this by the sound and speed of the engine. If an adaptor screw is fitted in manifold, the carburetter can be set with a vacuum gauge.

All threads and dimensions on carburetter are METRIC.

Carburetter Jet Sizes

26 VA

30 VEI "65 Sports"

Choke Jet

17 m.m.

Choke tube

21 m.m.

Main Jet

57 m.m.

Main Jet

95 m.m.

Comp Jet

50 m m

Comp Jet

40 m.m.

Slow Running Jet 60 m m

Slow Running Jet

60 m.m.

Progression Jet

50 m.m.

Cap Tube

2 m.m.

Needle Seating

1.5m.m.

Needle Seating

1.5 m.m

Capacity Tube

2 m.m.

Progression Jets?

30 VEI "Nippy"

30 VEI "Speedy"

Choke Tube

21 m.m.

Choke Tube

25 m.m.

Main Jet

85 m.m.

Main Jet

120 m.m.

Comp Jet

55 m.m.

Comp Jet

40 m.m.

Slow Running Jet 60 m.m.

Slow Running Jet

60 m.m

Needle Seating

1.5 m.m

Cab Tube

2 m.m.

Progression Jet

90 m.m

Progression Jet

90 m.m.

Carburetter Threads

No. in parts schedule

Butterfly Spindle

6 m.m. x 1 m.m.

51

4 m.m. x .077 m.m.

Choke Cover Bolt

6 m.m. x 1 m.m.

Choke Cover Bolt 5

m.m. x .080 m.m.

14

Choke Cover Bolt 6

m.m. x 1 m.m.

16

Air regulating screw 5 m.m. x

.080 m.m.

3

Throttle stop screw 5 m.m. x

.080 m.m.

13

Adjusting screw for interconnecting lever

4 m.m. x .070

10 & 11

Emulsion block screw 4 m.m. x

.070m.m.

30

Emulsion block screw 3 m.m. x

.050m.m.

31

Bowl bolts

7 m.m. x 1 m.m.

1& 2

Banjo bolts

12 m.m. x 1.25 m.m,.

49

Carb jet needle

11 m.m. x 1.50 m.m.

45

Carb jet Comp

13 m.m. x 1.50 m.m.

39

Carb jet Main

11.m.m. x 1 50 m.m.

36

Carb jet Slow Running 6 m.m. x 2.75

m.m.

41