The Zenith 24T2 Carburettor

Introduction

After the war ended, basic petrol ration was restored in June 1945, withdrawn in

mid-1947 and re-introduced in June 1948 at a third of the previous value. Petrol

rationing continued until May 1950. New cars produced in the UK were nearly all

diverted overseas to earn foreign income and it was impossible to buy a new car

until after 1950, unless special condition applied (e.g. you were a doctor or

other essential user). This led to many pre-war cars being recommissioned after

a period of storage, which worked well in the case of late 30s cars (Rubies and

Big Sevens) with a few tens of thousands of miles on the clock; such cars, if

they had been carefully laid up were in almost new condition and commanded high

prices. Older cars (in our case, Box saloons etc.) may have had more miles and

their condition was variable. Many vintage cars (Chummies and Top Hats of

various types) had already been scrapped before the war; those that survived

would have been the better, less used examples.

A particular problem existed with the 1929 – 32 cars. These had a 15mm choke,

Zenith updraft carburettor based on the earlier bronze 22FZ type but made using

an injection moulding technique and termed the 22FZB. The material was changed

to “MAZAK”, a smooth flowing casting alloy of Magnesium, Zinc, Aluminium and

Chromium. This material was subject to corrosion, probably due to high levels of

Magnesium and by 1945, many 22FZB carburettors were weakened by corrosion,

leading to cracks and breakage. The Zenith Carburettor Company was helpful and

adapted a carburettor, already in post war production, so that it could be

bolted on to an Austin Seven to replace a broken 22FZB.

The carburettor that was used was the 24T2, an updraft fitted to the Ferguson

T20 tractor and various stationary engines, mainly of JAP, Lister, Petter and

Villiers manufacture. These engines were used to power generators, concrete

mixers and other industrial and agricultural machinery. Zenith did some

development work and released a version of the 24T2 in the late forties or early

fifties, to satisfy the demand for getting older Austin Sevens roadworthy again.

There are some advantages to using this carburettor in place of the earlier

updraft types, most notably that the carburettor has better changeover from idle

to power and produces power more smoothly with better economy. It is also (if in

good condition), less prone to leaks and may be less susceptible to

vaporization. There are some disadvantages as well; it is very difficult to

clear a blocked jet at the roadside and the carburettor does not have a

“vintage” appearance. If you actually drive an early car however (rather

than using it for shows), the 24T2 may be an option worth considering.

produces power more smoothly with better economy. It is also (if in

good condition), less prone to leaks and may be less susceptible to

vaporization. There are some disadvantages as well; it is very difficult to

clear a blocked jet at the roadside and the carburettor does not have a

“vintage” appearance. If you actually drive an early car however (rather

than using it for shows), the 24T2 may be an option worth considering.

Buying a 24T2

There are a number of traps for the unwary. There are many versions of the 24T2,

with different mounting holes, main jet, throttle arrangements and so on.

Because the carburettor was used on many engines from the 2 litre Ferguson

Tractor (aka Standard Vanguard) OHV wet liner engine to 600cc single cylinder

concrete mixer engines, the version you may be looking at on a random Autojumble

stall is probably not an Austin Seven variant.

The key thing to look for is the Zenith

type number “F1372” stamped adjacent to the petrol inlet. If this number is

present, the carb was originally produced with the setting for use on a Seven.

The settings are as follows:

·

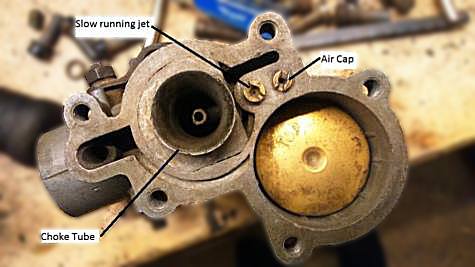

Choke tube 14

·

Main Jet 75

·

Slow Running jet 50

·

Air Cap 150

·

Needle valve 1.5

Any other number means that the carburettor has a different setting and while

this may be able to be changed, some carbs were produced with physical

differences that preclude this.

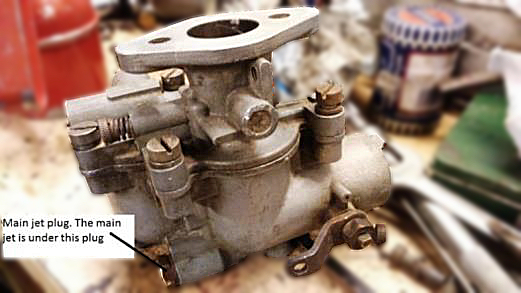

Regarding condition, the main thing to consider is the state of the main jet

housing and thread, which is covered by a brass plug, below the petrol input.

Check that the brass plug can be unscrewed and that the long thread revealed is

sound, especially where the plug fits as it is essential that this can be

tightened fully. Underneath the plug,

at the end of the thread is the main jet; this should be a 75 (0.75mm dia) and

it should unscrew, revealing a red fibre washer beneath. Ensure that you use a

parallel, well-fitting screwdriver to release this jet as a wedge screwdriver

will damage the vulnerable thread.

Unfortunately, many carburettors on offer will fail at this point because they

may have been stored on engines, out in the open and filled with water, causing

corrosion of the MAZAK. Previous “mechanics” may also have damaged the thread by

using the wrong screwdriver. If the type number is right and the main jet thread

looks good, you can buy the carb and move on to overhaul.

Overhauling the 24T2

Start by stripping the carb down entirely and checking that the setting, given

above, is correct. The throttle spindle will be worn. Remove the two screws and

the butterfly disc which will enable the throttle spindle to be removed. Inspect

the castings and try the new spindle for fit. There should be negligible play in

the spindle; the casting can be bushed if very worn but this is quite expensive.

Excessive play at this point will cause slow running issues later. Soak the

castings in cellulose thinners to remove the petrol gum. The gasket will have

shrunk and must be replaced.

Overhaul kits are available from Burlen Services and contain a throttle spindle,

screws and disc, gasket, washers and a new needle valve. Unfortunately, 75 main

jets are unobtainable at the moment.

However, 82 jets are available and may “do” at a pinch.

Inspect the main jet thread, it is a metric thread, 10mm dia, 1.0mm pitch.

Tooling is available from Tracy Tools in Devon, however there is very little

meat here to effect repairs and this thread must be in good condition.

repairs and this thread must be in good condition.

Make sure that the top and the bottom faces of the carb are flat and true; if

necessary use a piece of glass and some “wet or dry” to face them off. You may

need to remove the choke tube to do this but be careful not to damage the tube

or the seating.

The choke tube must be firmly fixed in the housing, if it has worked loose it may have worn both tube and housing which results in the tube sitting low. You may be able to rectify with some gaskets, cut from thick paper, aiming to get the tube slightly above housing level and thus held in when reassembled.

The top mounting flange will be warped and can be carefully faced off with a

sharp, 2nd cut file, making sure that all traces of filings are removed in the

cleaning bath.

After cleaning, blow through all passages with compressed air or a tyre pump and

lay out the parts, ready for assembly. Make sure all the jets and passages are

completely clear. Replace the throttle spindle with the new item from the

overhaul kit, screw in the new butterfly disc and lock the screws into

position. Replace the operating arm and reassemble the carb with a new gasket,

not forgetting to add the float and its valve.

Fitting a 24T2

You will need to fit a ball joint type connection to the operating arm for the

throttle. These are usually fitted to 26VA carburettors on later cars. Make sure

you can get the full range of movement and adjust so that the throttle fully

closes when released. Choke connection will depend on your car; the standard

wires will probably need a special link bending to fit. Note that the input

gasket supplied in the rebuild kit will be too large; use a gasket from one of

the A7 suppliers or cut one from thick paper.

connection will depend on your car; the standard

wires will probably need a special link bending to fit. Note that the input

gasket supplied in the rebuild kit will be too large; use a gasket from one of

the A7 suppliers or cut one from thick paper.

The petrol input will probably need a special feed pipe making up. Make sure that petrol is always flowing downhill, never up. You must have a good, fine filter on the input because the main jet is not easy to clear in the event of a blockage, requiring the removal of the carburettor, which is not a quick job at the roadside. You can use an external filter, suitable for gravity feed or a fine mesh filter in the input banjo.

Once the carburettor is fitted, adjust the air screw about one or two turns off

its seat and start the engine. Set the idle speed and adjust the air screw for

slow, even running, with no noticeable “fluffing” when the throttle is opened.

Finally, road test and enjoy!

Tim Reynolds BA7C with very many thanks for a brilliant article