For some time I have been trying to identify

a regular howling noise in my LWB Box which comes in round about 30 mph to 36

mph. One bright idea, having gone through so many alternatives, it might be a

slightly wobbly flywheel. So out comes the engine to reveal, indeed, slight

play of the flywheel. A bit of lapping, checking the flywheel isn’t leaning

against the back of the rear bearing and back went the engine. While the

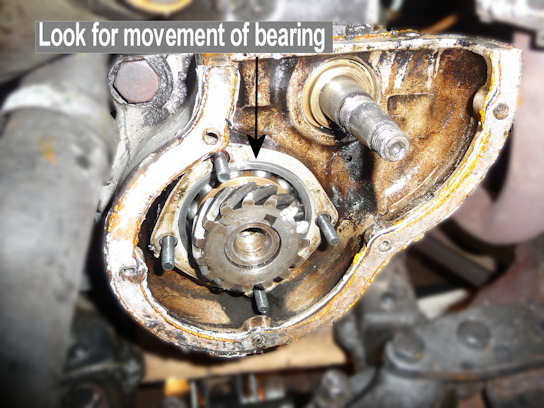

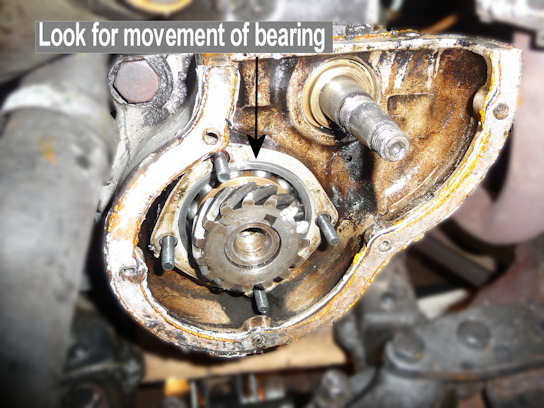

flywheel cover was still off I thought I would check everything by pushing down

on the clutch. HORROR! The flywheel was moving fore and aft by about 5 mm.

What I had diagnosed as flywheel wobble was, in fact, longitudinal movement of

the crank!

At my darkest hours I always find the Munwellyn Boys able to shed much light and common sense.

Clearly, what often happens is the two front bearings either lose their grip on the crank or have started to rotate within their housing so losing grip in the crankcase. Either way, the crank can now move forward and backwards with the clutch and flywheel.

The solution is terribly simple – insert a shim at the very front of the bearings between the bearing outer ring and the retaining plate behind the starter dog. The correct shim is a Triumph Herald piston ring which every member of the “never throw anything away” brigade will have in a box in some dark corner. One additional advantage to this simple procedure is that the engine doesn’t have to come out – just the radiator and nose piece.

Unfortunately, it didn’t cure the vibration

but the clutch works a lot better!

David Whetton