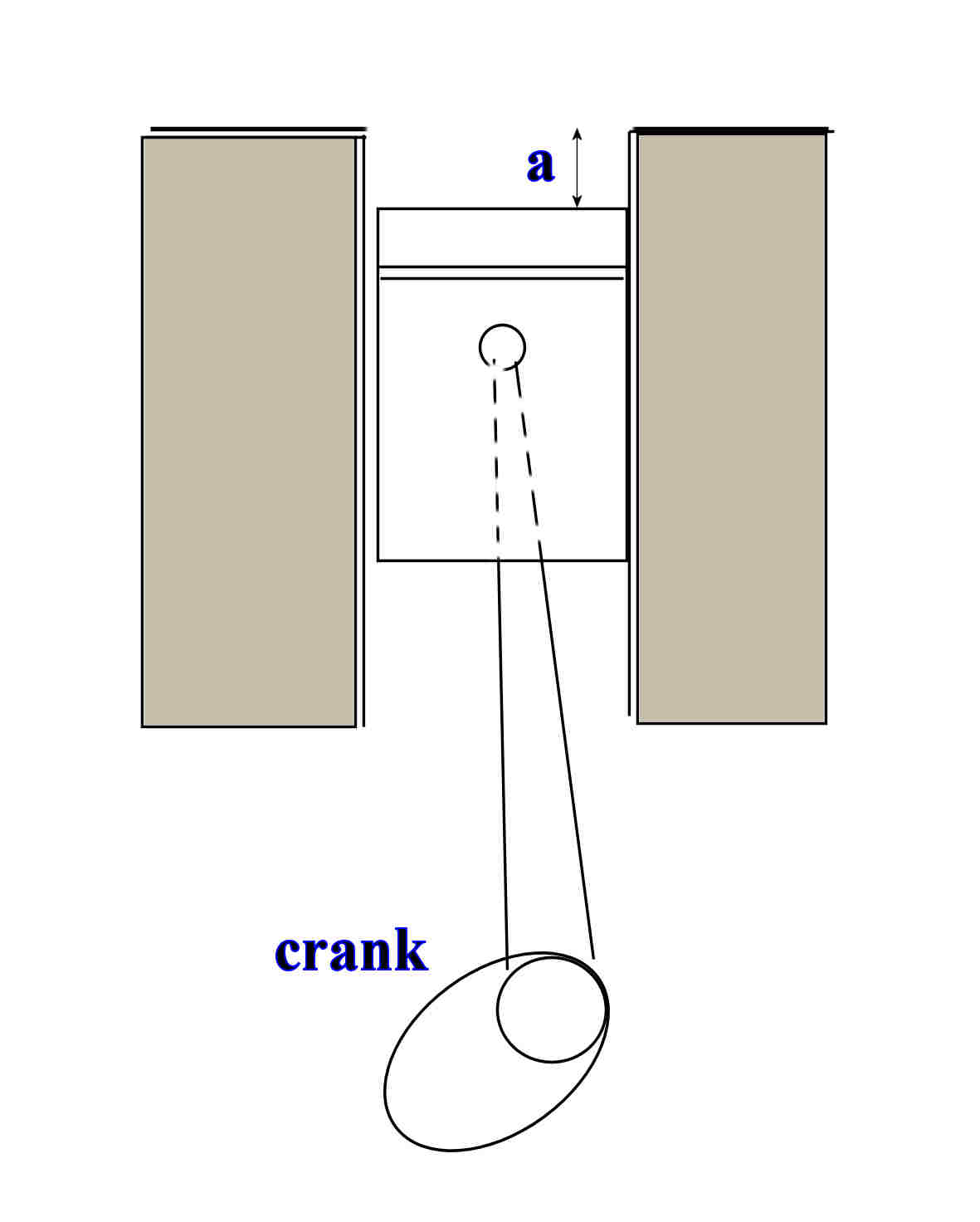

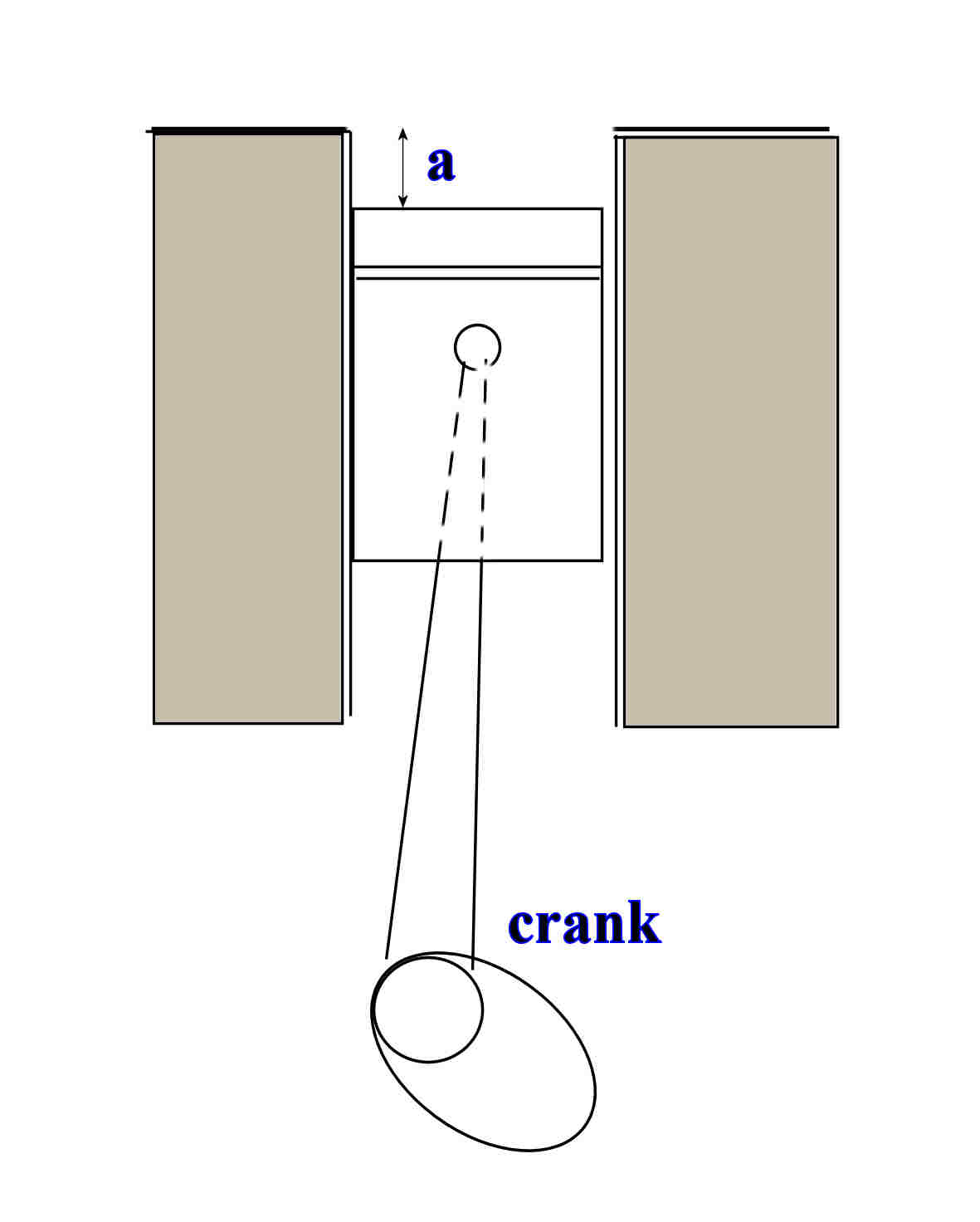

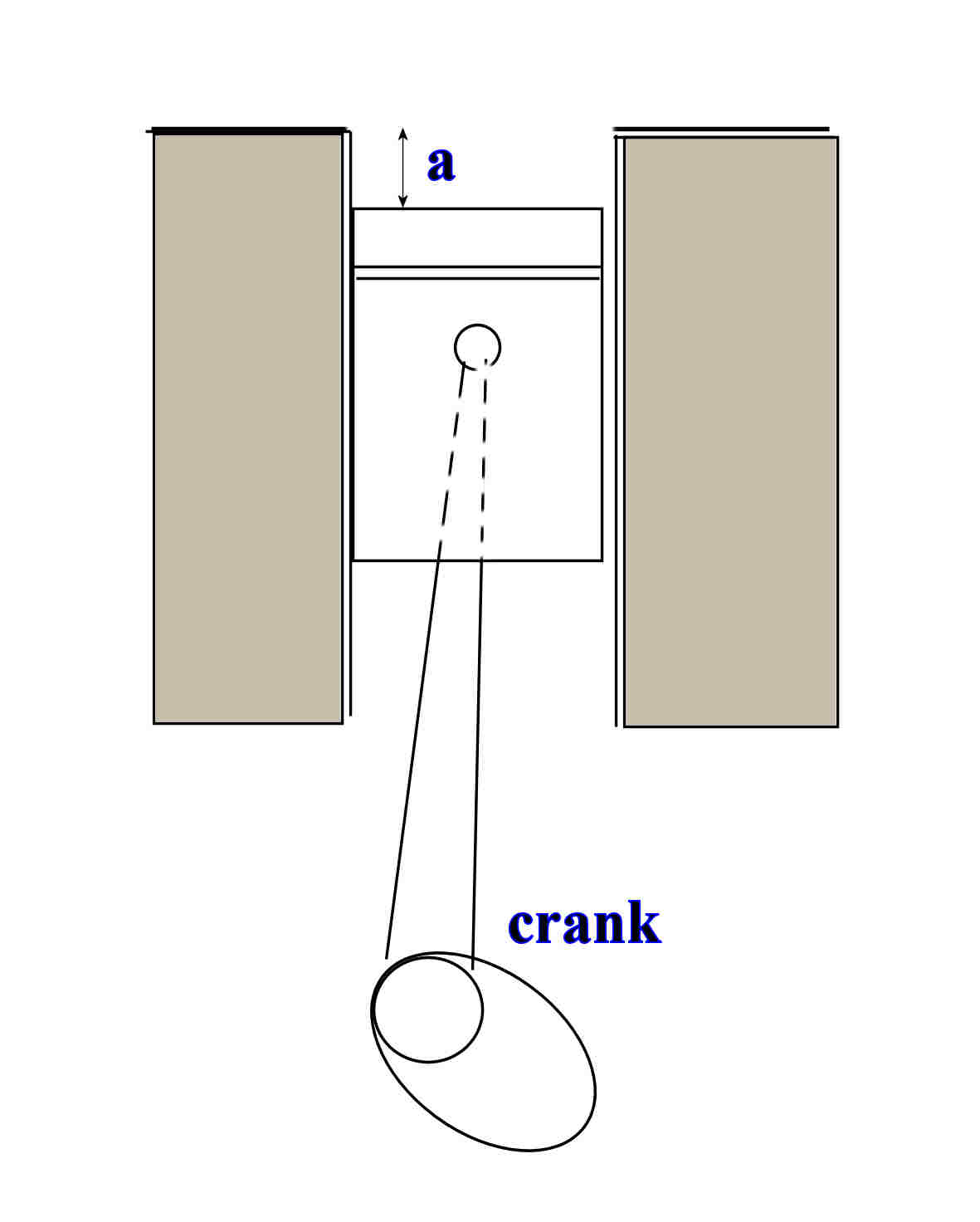

This experiment came out of a chance conversation with Chairman Bernard who was casting doubt on the 1/4 mark on the Austin Seven flywheel not being true top dead-centre (TDC). TDC is traditionally defined to be the point at which the number 1 piston is at the top of its stroke and, as we all know, timing figures are measured from this point—BTDC (before tdc) or ATDC (after tdc). The problem with measuring TDC is the rotation of crankshaft and hence the up-and-down movement of the piston is flat at the very point we want to measure it with absolutely minimal movement. The approach I have taken is to find the halfway point between two equal extremes: If the downward movement of the piston is the same distance (a) on each side of the stroke then the crank must be the same number of degrees either side of TDC. The advantage of this method of measuring is that there is good movement of the piston crown at the point of measuring making it more accurate. The angle of the crank is easily measured on the flywheel using Tippex as a marker.

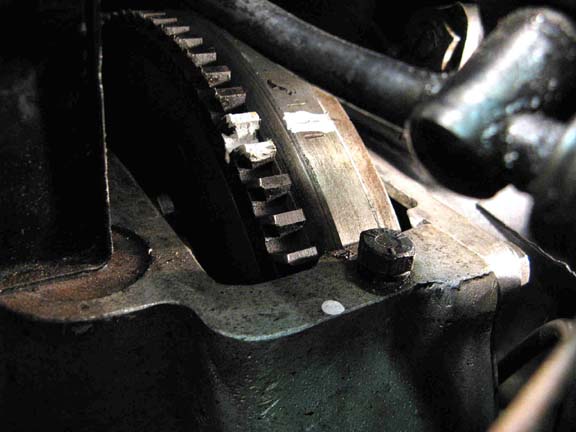

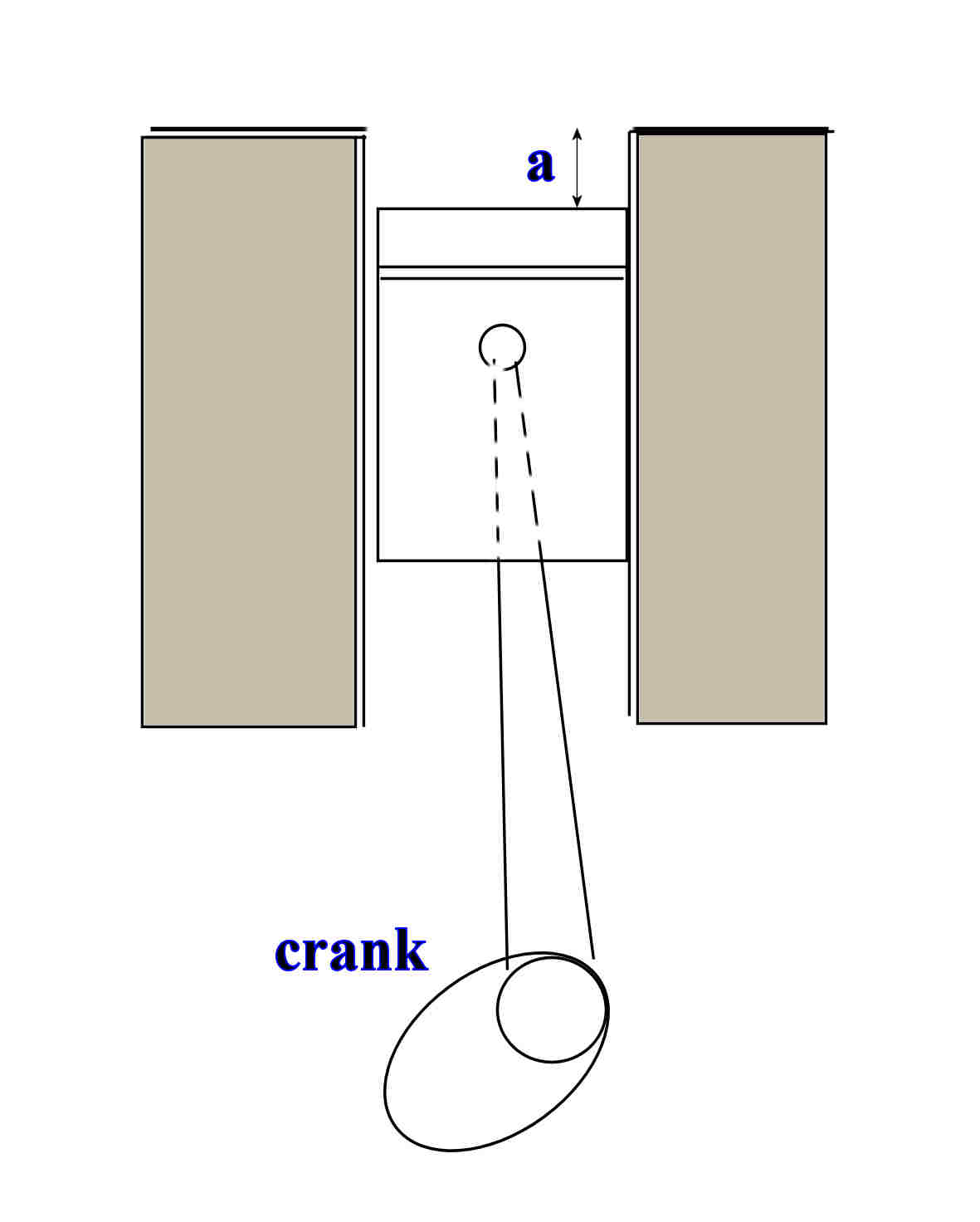

METHOD: Remove flywheel cover Remove plug No.1 Stick thumb over plug hole and rotate the crank (using the starting handle—you may need an assistant if you’ve got short arms!) until pressure is felt indicating TDC. Mark the teeth on the starter ring next to the 1/4 (TDC) mark on the flywheel with Tippex. Rotate the crank to drop the crown of the piston until the Tippex marks are exactly adjacent to the edge of the crankcase cover—this will give a datum line. (See photo 1). Measure the drop of the piston crown—I used an old hacksaw blade, dropped it into the cylinder and marked its depth against the threads on the plug hole with Tippex. (See photo 2) Remove hacksaw blade and rotate crank until the Tippex mark beside the 1/4 mark on the flywheel appears on the other side of the crankcase cover. Replace hacksaw blade and slowly rotate flywheel (you may need to use a gloved hand to move the flywheel back and forwards) until the marks on the hacksaw blade are exactly lined-up as before. Observe where the mark on the flywheel is now. On my Box it was 4 teeth to the side. (See photo 3).

CALCULATION: There are 80 teeth around the Box flywheel so 1 tooth = 4½o so TDC was half of 4 x 4½ = 9 degs or 2 teeth BTDC.

![]()

![]() CONCLUSION: If you want exact TDC then set the 1/4 marks on the flywheel 2

teeth to the right when looking at the flywheel from the front of the car.

Otherwise, apart from the interest, I’m not sure what the implications for this

is—perhaps others with more mechanical knowledge can contrib

CONCLUSION: If you want exact TDC then set the 1/4 marks on the flywheel 2

teeth to the right when looking at the flywheel from the front of the car.

Otherwise, apart from the interest, I’m not sure what the implications for this

is—perhaps others with more mechanical knowledge can contrib![]() ute

to the issue. David Whetton

ute

to the issue. David Whetton