PETROL PUMP PRIMING LEVER: The first warning I had of trouble was the engine cutting out while hurtling down a hill. Then the engine cut out completely while running at full chat. Removal of the float chamber showed it to be empty. While exhibiting at the rally with the bonnet open someone must have operated the manual priming lever on the AC T-type petrol pump. The lever had stuck. This meant each stroke of the pump delivered a reduced volume of petrol. The car ran perfectly for miles and it was only when driven hard that the restricted petrol supply manifested itself. A few strokes of the priming lever making sure it was left fully down and we were away again. Examination of the pump showed the priming lever’s arms to be binding on the external spring which is meant to return it. Two bright spots on the spring showed it must have been happening for some time. Slightly widening the legs of the lever allowed it to miss the spring, the lever moving up and down freely. Many of our cars will have the T-type pump and could be at risk. I suppose the problem is most likely to be at the start of the season if the car has been standing. I understand the alternative M-type pump doesn’t have a priming lever. Essex A7C with thanks.

PETROL PUMP - FUEL BLOCKAGE: After repeated stops due to a fuel blockage on the way home from a run (cured temporarily by blowing down the filler tube on the tank!) The following day I removed the petrol pump and split it into two by removing the ring of small screws, expecting to find a split diaphragm which in fact was not the case. As the two halves came apart, a very small screw could be seen drifting quite remotely from the pump itself. In the upper part of the pump is what appears a small gauze held in place by three small screws, one of which was my offending screw. The ‘repair' was a simple reinsert of the screw and a check of the other two. The two halves of the pumps were reassembled, including use of the new diaphragm, and then reattached to the car making sure the foot of the pump, which is reinserted first into the hole of the crankcase, rests on the cam and is not hooked under it. This can be checked by slowly turning over the engine with the starting handle. If the pump is incorrectly fitted the en-gine will jam solid. Peter Trebilco DA7C

S.U. FLOAT VALVE FOR SCUTTLE-MOUNTED TANK: If y

ou

have an A7 fitted with an SU carb and have a front mounted fuel tank

that sits higher than the float chamber, it will probably leak fuel. The

answer is to fit a replacement float valve kit that incorporates a viton

rubber tip. These are available from Burlin Services (SU Carbs Ltd) and

I can confirm that they do work. Geoff Kingsland DA7C

ou

have an A7 fitted with an SU carb and have a front mounted fuel tank

that sits higher than the float chamber, it will probably leak fuel. The

answer is to fit a replacement float valve kit that incorporates a viton

rubber tip. These are available from Burlin Services (SU Carbs Ltd) and

I can confirm that they do work. Geoff Kingsland DA7CFUEL LINE BLOCKAGE 2: Keep a bycycle pump in the car to help blow-through the petrol pipe.

Henry

Nicholson-Cole DA7C

Henry

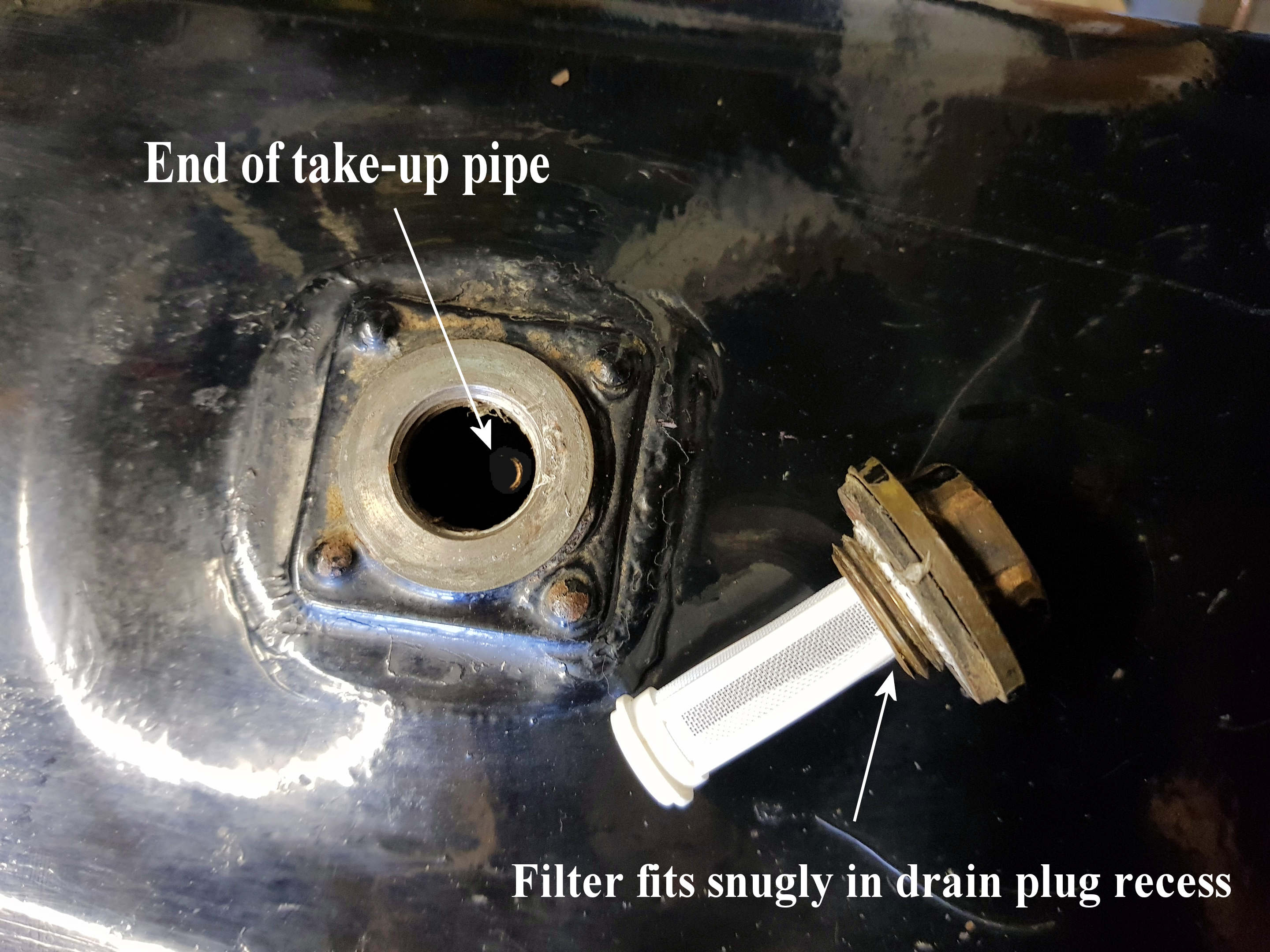

Nicholson-Cole DA7C left me stuck at the side of the road because

of flaked tank coatings blocking the fuel

pipe inlet at the petrol tank. Short of removing the tank it is a difficult

problem to deal with. Our Box Saloon had a tank coating done by me around 30

years ago. It has caused me to be stuck twice due to on-going flaking of the

coating. I have flushed it out twice and have found a small suitable filter

to slip over the inlet to avoid pipe blockages. This is cheap and easy to

fit and will suffice to keep you rolling. I recommend that when the fuel

level gets to around a gallon the tank is drained into a bowl a couple of

times a year just to avoid any major build up. The filter cannot close off

the inlet to the pipe as the pipe is held in place by a metal stay. This in

turn prevents the filter from closing off the inlet. The area of the surface

exposed to the fuel filter area is greater than the inlet area of the fuel

pipe. The protruding filter sits comfortably into the recess in the tank

drain plug. The filter can be obtained from Austin 7 Components (https://www.a7c.co.uk/spares.php#nogo)

part no BE24f in the catalogue index. Scroll down to “Fuel System” and

it’s listed as “Zenith 22ZF carb filter” about £8. George

Mooney DA7C

left me stuck at the side of the road because

of flaked tank coatings blocking the fuel

pipe inlet at the petrol tank. Short of removing the tank it is a difficult

problem to deal with. Our Box Saloon had a tank coating done by me around 30

years ago. It has caused me to be stuck twice due to on-going flaking of the

coating. I have flushed it out twice and have found a small suitable filter

to slip over the inlet to avoid pipe blockages. This is cheap and easy to

fit and will suffice to keep you rolling. I recommend that when the fuel

level gets to around a gallon the tank is drained into a bowl a couple of

times a year just to avoid any major build up. The filter cannot close off

the inlet to the pipe as the pipe is held in place by a metal stay. This in

turn prevents the filter from closing off the inlet. The area of the surface

exposed to the fuel filter area is greater than the inlet area of the fuel

pipe. The protruding filter sits comfortably into the recess in the tank

drain plug. The filter can be obtained from Austin 7 Components (https://www.a7c.co.uk/spares.php#nogo)

part no BE24f in the catalogue index. Scroll down to “Fuel System” and

it’s listed as “Zenith 22ZF carb filter” about £8. George

Mooney DA7CNEW PETROL TAP CORKS are available from Brit-Bits in Barrack Road, Christchurch. Before fitting them do not try and reduce the diameter even though they may appear to be too fat. First boil them in a saucepan for 10 minutes to make them pliable then fit them on to the spindle, smear a little Vaseline on to the cork and ease it into the body of the tap, it may be a little stiff at first but will soon ease up when in contact with the petrol. Glyn. Brit-Bits is open Wednesday to Saturday 9-1pm for callers, tel 01202 483675 and has moved to the rear of Smart Riders on 185a Barrack Road, Christchurch. The website www.britbits.co.uk gives an idea of the range of items stocked which can be sent by mail order.

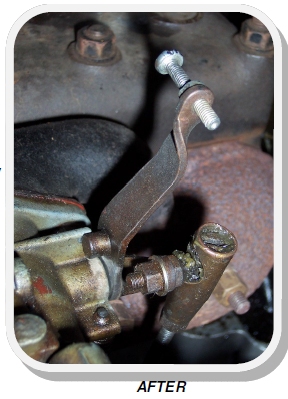

throttle flap open –

is adjustable? It has a brass head on a

threaded ro

throttle flap open –

is adjustable? It has a brass head on a

threaded ro d that can be screwed in and out (after removing the connecting ball

joint). See Bob’s photos.Put

a heavy weight or wife’s foot hard on the accelerator pedal and check to see if

the throttle flap is wide open. If not,

screw out the accelerator linkage until it is.

The result? – instant performance. From an idea by

Bob Kneale

in the Cornwall A7C newsletter with many thanks.

d that can be screwed in and out (after removing the connecting ball

joint). See Bob’s photos.Put

a heavy weight or wife’s foot hard on the accelerator pedal and check to see if

the throttle flap is wide open. If not,

screw out the accelerator linkage until it is.

The result? – instant performance. From an idea by

Bob Kneale

in the Cornwall A7C newsletter with many thanks.If you suspect you may have an induction leak around the carb or manifold, spray on some carb or brake cleaner from a can whilst the engine is running and, if the engine is sucking in air, there will be an immediate and noticeable increase in engine revs. Colin Chalk DA7C

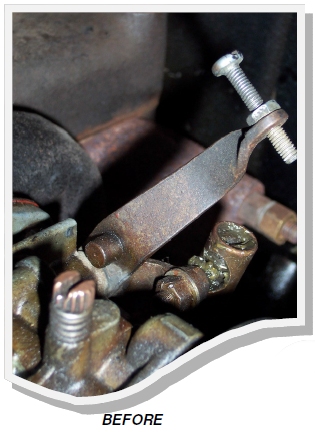

neat

blanking plate can very quickly be sawn, filed and drilled from an

offcut of 1/8” steel and it is an ideal opportunity to add a bracket to

carry the bottom-end of a second throttle return spring as shown in the

photo.Kindly reproduced from the Herefordshire A7C with many thanks.

neat

blanking plate can very quickly be sawn, filed and drilled from an

offcut of 1/8” steel and it is an ideal opportunity to add a bracket to

carry the bottom-end of a second throttle return spring as shown in the

photo.Kindly reproduced from the Herefordshire A7C with many thanks.REAR PETROL TANK LEAKS: When you service the car, check the tank for leaks and rust by stroking the underside of the tank with the palm of your hand feeling for any slightly raised bulges. It is fairly common for a leak due to a pin-prick hole to be contained by layers of old paint. However, there is a simple solution - use a product called Petro Patch Putty available from Amazon and motor accessory shops such as Motobitz. Empty the tank and let it dry out; scrape off the old paint bubble; rub back to bare metal and apply the putty; when dry, sand back to smooth. David Whetton DA7C

ETHANOL PROBLEMS: Ethanol dissolves the lead and tin in the solder on fuel float (and possibly fuel lines and carburettor) and causes it to sink and flood. Carry a spare float. Ethanol Mate or John Deere Mate are fuel stabilisers. Some plastic floats are now available and hopefully A7 will be available soon. Supplier: Burlen Ltd. Salisbury. DA7C TECH FORUM