tapping the fixing bar for the side water manifold in the block, you need to

be very careful only to drill and tap the bar itself as the central cylinder

bores are immediately behind it and, if not careful, you will pass through

straight into the barrel itself rendering the block only repairable with a

new cylinder sleeve! The same care needs to be taken, of course, when

screwing in your fixing stud or bolt. If the bolt is too long,

the same will

occur! Beware. Gary Munn.

tapping the fixing bar for the side water manifold in the block, you need to

be very careful only to drill and tap the bar itself as the central cylinder

bores are immediately behind it and, if not careful, you will pass through

straight into the barrel itself rendering the block only repairable with a

new cylinder sleeve! The same care needs to be taken, of course, when

screwing in your fixing stud or bolt. If the bolt is too long,

the same will

occur! Beware. Gary Munn. Vince Leek advises sliding an old hacksaw blade down behind the casting, as shown in the picture, to protect the wall of the cylinder in the event of over-drilling or slipping.

928 Austin Seven seems to run hot, but there are no signs of

boiling. I am wondering if you can give me your advice as to the cause.

A: Overheating such as you are experiencing need not unduly alarm you

unless, of course, you find that the engine boils when you get a long climb

or much low gear work. Theoretically, so long as the water is not boiling,

the hotter the engine runs the more efficient it is, providing that the

over-heating is not due to some defect within the engine itself. Overheating

arises from a number of causes. It may be that your ignition is too retarded

so that the gases burn slowly and have contact with a bigger area of the

cylinders than normally, thus taxing the cooling system. Again, if the

mixture on which you are running is weak, there will be similar results due

to slow combustion. There is also the possibility that your fan is slipping,

due to the belt-tension needing adjustment, or perhaps the radiator has

become choked with mud. The remedy in each of these instances is quite

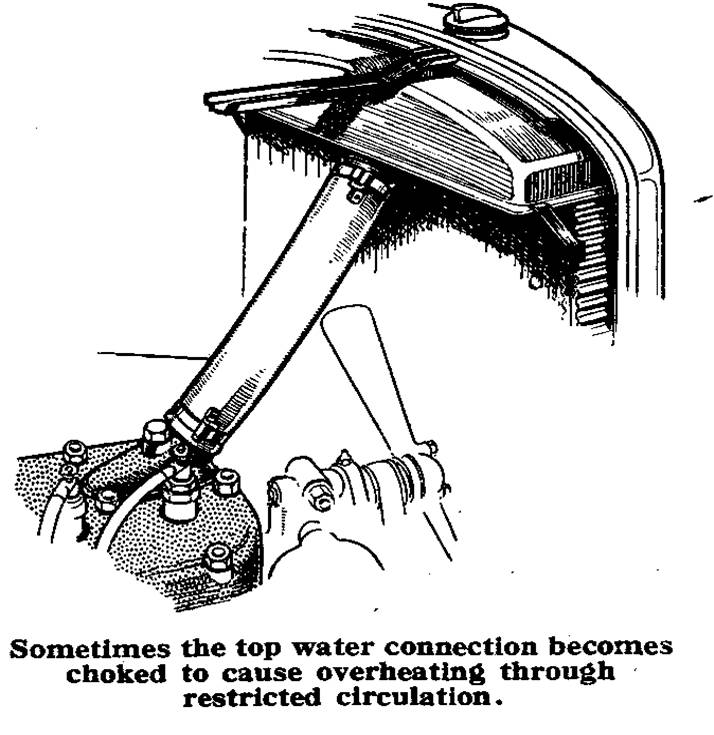

simple. Another possibility is a choked water connection interfering

with the circulation. If you find after a run that the temperature of the

top of the radiator is markedly different from that at the bottom, you

should remove the top hose connection and see whether it has frayed inside

to restrict the circulation, in which event a new connection should be

fitted.

928 Austin Seven seems to run hot, but there are no signs of

boiling. I am wondering if you can give me your advice as to the cause.

A: Overheating such as you are experiencing need not unduly alarm you

unless, of course, you find that the engine boils when you get a long climb

or much low gear work. Theoretically, so long as the water is not boiling,

the hotter the engine runs the more efficient it is, providing that the

over-heating is not due to some defect within the engine itself. Overheating

arises from a number of causes. It may be that your ignition is too retarded

so that the gases burn slowly and have contact with a bigger area of the

cylinders than normally, thus taxing the cooling system. Again, if the

mixture on which you are running is weak, there will be similar results due

to slow combustion. There is also the possibility that your fan is slipping,

due to the belt-tension needing adjustment, or perhaps the radiator has

become choked with mud. The remedy in each of these instances is quite

simple. Another possibility is a choked water connection interfering

with the circulation. If you find after a run that the temperature of the

top of the radiator is markedly different from that at the bottom, you

should remove the top hose connection and see whether it has frayed inside

to restrict the circulation, in which event a new connection should be

fitted.

RAD COWL RIVETS:

the correct size of rivets used to attach the neck to a brass radiator

cowl for an Ulster re-build are 1/8" dia x 1/4". Best to use copper

round head ones. Many thanks to Willie McKenzie

THE RADIATOR OVERFLOW PIPE sometimes fouls the cross-member on the Austin Seven and together with the possibility of corrosion at this point it seems logical to do something about the problem. Bart Walsh's method is to slide on a short length of clear plastic piping on to the end of this tube which can then be led to any point where any overflow can be directed away from vulnerable areas.