|

HANDBRAKE LEVER: Excessive

handbrake lever

travel on late Ruby Saloons, where the hand brake moves nearly full

travel even if the brakes are in good adjustment, is usually caused by

the diameter of the wheel that touches the actuating lever on the cross

shaft. Remove the hand brake lever assembly, remove the wheel and

replace it with five, 1Ē diameter plain washers with a 5/16"

hole. In most cases this will remove the free play completely. |

|

CABLE BRAKES: When adjusting Austin 7

cable brakes

(on

cars with coupled brakes) with all 4 wheels jacked off the ground, have

a mate apply medium pressure to the brake pedal, or if all your mates

are down the pub, wedge a block of wood between the seat and the pedal,

and test the resistance on each wheel. It is most important that the

brakes are tested from the footbrake rather than the handbrake, as the

latter acts on the centre of the cross-shaft rather than from the

offside end. The difference being the handbrake wonít pull and twist

the shaft, especially if the brakes are worn, in the same way as when

the pedal is used in normal road conditions. As you all know the cables

should be adjusted so that the front brakes come on slightly in advance

of the rear and the near≠side rear should under light pedal pressure

come on slightly more than the offside rear, so that under heavier

pressure as the cross-shaft moves they equal themselves up. Having

successfully adjusted the cables, go for a test drive and join your

mates down the pub to celebrate. |

|

HYDRAULIC BRAKE ADJUSTERS:

Morris Minor brake cylinder

adjusters can be reversed so that the screwdriver slot faces the back

plate. Drilling the appropriate hole would allow adjustment from the

rear. The hole needs to be 3/8" as the adjuster changes position

as it is adjusted and you also need to cover the hole as well to keep

water out. All this means that by drilling a couple of carefully

aligned holes in the back plate it saves all that hassle of drilling

the cast iron brake drums and removing the wheels every time you want

to adjust your brakes. |

|

BRAKE CAM ADJUSTERS:

If new

brake cams

have a sharp edge where they push against the brake shoe, it must be

rounded off. Also, look for a groove that may have been worn in the old

brake shoe by previous cams. Should your brakes lock-on, it may be that

the cam has lodged underneath the groove. In which case, drive the car

in the opposite direction and it should release. In a worst case, a

plate can be attached to the end of the brake shoe to remove the groove. |

|

BRAKE LININGS: When removing

old brake linings,

donít drill out the old ones as this may damage the shoes. Instead, break off

the old lining, if it will come, and hacksaw off the heads of the old rivets

then punch out the remaining bits. If they donít break off, just carefully

put the saw blade between the lining and the shoe and proceed as above.

Glyn Llewellyn

|

REPLACING BRAKE SHOES:

When

replacing brake shoes,

especially the fronts, take off the hubs first to remove and replace shoes.

It saves a lot of sore fingers, a lot of time in the end, and gives you a

chance to check and grease the bearings. Ian Mason-Smith

REPLACING REAR BRAKE SHOES

1. Check the brake shoe pull-off springs. Replace elongated or

miss-shaped springs with new.

2. When you have to reconnect the last brake shoe spring, loop a length

of string through the spring hook, pull it tight and tie-off on

something. Now push the spring in position around the hook on the brake

shoe with a screwdriver. Release string. Remove string. Job done!

3. It is most important that the brake linings are not impregnated with

grease, etc. Stick masking tape on the linings to protect them until the

dirty work is done then just peel it off.

4. When you have replaced the brake linings you probably will not be

able to get the brake drum on again. Remove any adjuster you have on the

cable. If the drum still will not go on, slacken off the foot pedal

adjusting screw. This allows the brake cross-shaft to turn back and

allows the brake shoes to fully return to normal. Now the drum should go

on. If not, bad luck! It means you have to slacken the clamp bolt

in the brake cable forked end and pull the cable out a bit. Terrible

job! Don't pull it right out as it is a so and so of a job to get it

back into the forked end again!

With thanks to Viv Orchard from the IOW A7 Club |

SNAIL

ADJUSTERS:

There are two types of

snail

adjusters in use on Morris braking systems. The smaller type is used

on the front brakes because there are two leading shoes !! The rear has only

one leading shoes so a larger snail adjuster with greater lift because there

is only one in the rear brake. If a small adjuster is fitted to the rear

brake it will barely lift the shoe to a contact point for the brake shoe

with the drum leading to virtually all the braking on the front axle. Take a

look at your hydraulic brakes if you are NOT aware of this technical

feature. You may find a problem that you were did not know you had.

George Mooney DA7C two leading shoes !! The rear has only

one leading shoes so a larger snail adjuster with greater lift because there

is only one in the rear brake. If a small adjuster is fitted to the rear

brake it will barely lift the shoe to a contact point for the brake shoe

with the drum leading to virtually all the braking on the front axle. Take a

look at your hydraulic brakes if you are NOT aware of this technical

feature. You may find a problem that you were did not know you had.

George Mooney DA7C |

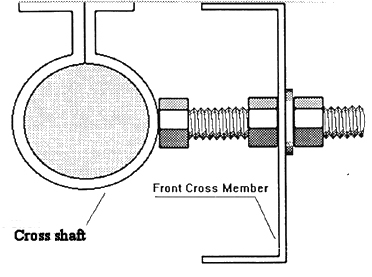

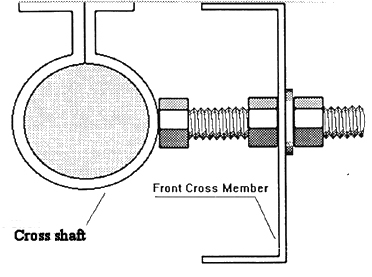

IMPROVING REAR

BRAKES ON PRE-1930 SEVENS:

Earlier Sevens with uncoupled brakes suffer from a very spongy pedal, due to the amount of flexing in the

brake linings. Most of this is because the cross-shaft bearings are made

from strip, and move considerably under braking force. A quick mod. can

be done to improve this. It takes half an hour or so, needs no

dismantling, and the only materials needed are a 5/16 BSF x 2Ĺ" bolt,

spring washer and two pins. Drill a 5/16" hole in the front cross member

in line with the centre of the offside cross shaft bearing, and insert

the aforementioned bolt with one nut on, fit the washer and second nut.

Adjust so it bears against the cross shaft. That's it! As a bonus, this

will also give a fine adjustment for balancing the rear brakes. Mike

Phelan PWA7C

suffer from a very spongy pedal, due to the amount of flexing in the

brake linings. Most of this is because the cross-shaft bearings are made

from strip, and move considerably under braking force. A quick mod. can

be done to improve this. It takes half an hour or so, needs no

dismantling, and the only materials needed are a 5/16 BSF x 2Ĺ" bolt,

spring washer and two pins. Drill a 5/16" hole in the front cross member

in line with the centre of the offside cross shaft bearing, and insert

the aforementioned bolt with one nut on, fit the washer and second nut.

Adjust so it bears against the cross shaft. That's it! As a bonus, this

will also give a fine adjustment for balancing the rear brakes. Mike

Phelan PWA7C |

REFITTING GIRLING BRAKE SHOES:

After

relining brake shoes it can be quite a fiddle fitting them once more

with the springs connecting the shoes together behind the hubs. For

older Sevens itís usual to remove the hub but that shouldnít be

necessary for the later Girling brakes aided by the springs with a

little loop at each end into which a specific tool can be used to pull

the springs or one can use a combination of bullnose pliers and a large

screwdriver. However even then it seems that it would be easier to have

three hand with one holding the shoes in place whilst you try and fit

the springs! Instead itís useful to use large elastic bands to hold the

two shoes in place. A spring removal tool (not A7 specific) is

availble from most motor suppliers, or from eBay for under £5.

Peter Trebilco DA7C After

relining brake shoes it can be quite a fiddle fitting them once more

with the springs connecting the shoes together behind the hubs. For

older Sevens itís usual to remove the hub but that shouldnít be

necessary for the later Girling brakes aided by the springs with a

little loop at each end into which a specific tool can be used to pull

the springs or one can use a combination of bullnose pliers and a large

screwdriver. However even then it seems that it would be easier to have

three hand with one holding the shoes in place whilst you try and fit

the springs! Instead itís useful to use large elastic bands to hold the

two shoes in place. A spring removal tool (not A7 specific) is

availble from most motor suppliers, or from eBay for under £5.

Peter Trebilco DA7C

SNAGGING BRAKES IN

REVERSE:

Snagging brakes in reverse can happen for a variety of reasons and below

are some of the main reasons and my suggested remedies.

1. The bolt holding the rear of the radius arms is loose, spring is

broken or brass cups are worn. REMEDY: Replace, preferably all three,

with new. Check the fitting is secure.

2. Brake linings are not chamfered and/or overhang brake shoe.

REMEDY: Cut to size and/or chamfer with rasp file.

3. Nut(s) securing front of radius arm to axle beam are loose.

REMEDY: Ensuring radius arm is steady using a large spanner or grip,

tighten nut. (If radius arm is not steady during tightening it will

twist and, therefore, be able to flex under load, impairing braking

capabilities somewhat.)

4. Shackle pins and/or bushes are worn allowing whole beam to twist

under forward and reverse braking conditions. REMEDY: Replace with new.

Ensure that the bushes are tight fits in the axle and spring eyes. Any

movement will soon turn into lots of movement!!

5. King pins are loose or worn. REMEDY: Tighten king pin securing nut

initially. If this does not cure the slack then replace king pins and

bushes. Check the axle eye for ovality as this is more often the actual

problem. If you find this to be the problem the eye will need to be

repaired or another suitable beam found.

This is by no means definitive, although if any of the faults 1 - 5

exist it will undoubtedly have a negative effect on the braking

capabilities of the car and let's face it, Austin Sevens need all the

braking they can muster at the best of times!

Ruairidh Dunford with thanks to Meshing Point March 1999

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

two leading shoes !! The rear has only

one leading shoes so a larger snail adjuster with greater lift because there

is only one in the rear brake. If a small adjuster is fitted to the rear

brake it will barely lift the shoe to a contact point for the brake shoe

with the drum leading to virtually all the braking on the front axle. Take a

look at your hydraulic brakes if you are NOT aware of this technical

feature. You may find a problem that you were did not know you had.

George Mooney DA7C

two leading shoes !! The rear has only

one leading shoes so a larger snail adjuster with greater lift because there

is only one in the rear brake. If a small adjuster is fitted to the rear

brake it will barely lift the shoe to a contact point for the brake shoe

with the drum leading to virtually all the braking on the front axle. Take a

look at your hydraulic brakes if you are NOT aware of this technical

feature. You may find a problem that you were did not know you had.

George Mooney DA7C suffer from a very spongy pedal, due to the amount of flexing in the

brake linings. Most of this is because the cross-shaft bearings are made

from strip, and move considerably under braking force. A quick mod. can

be done to improve this. It takes half an hour or so, needs no

dismantling, and the only materials needed are a 5/16 BSF x 2Ĺ" bolt,

spring washer and two pins. Drill a 5/16" hole in the front cross member

in line with the centre of the offside cross shaft bearing, and insert

the aforementioned bolt with one nut on, fit the washer and second nut.

Adjust so it bears against the cross shaft. That's it! As a bonus, this

will also give a fine adjustment for balancing the rear brakes. Mike

Phelan PWA7C

suffer from a very spongy pedal, due to the amount of flexing in the

brake linings. Most of this is because the cross-shaft bearings are made

from strip, and move considerably under braking force. A quick mod. can

be done to improve this. It takes half an hour or so, needs no

dismantling, and the only materials needed are a 5/16 BSF x 2Ĺ" bolt,

spring washer and two pins. Drill a 5/16" hole in the front cross member

in line with the centre of the offside cross shaft bearing, and insert

the aforementioned bolt with one nut on, fit the washer and second nut.

Adjust so it bears against the cross shaft. That's it! As a bonus, this

will also give a fine adjustment for balancing the rear brakes. Mike

Phelan PWA7C  After

relining brake shoes it can be quite a fiddle fitting them once more

with the springs connecting the shoes together behind the hubs. For

older Sevens itís usual to remove the hub but that shouldnít be

necessary for the later Girling brakes aided by the springs with a

little loop at each end into which a specific tool can be used to pull

the springs or one can use a combination of bullnose pliers and a large

screwdriver. However even then it seems that it would be easier to have

three hand with one holding the shoes in place whilst you try and fit

the springs! Instead itís useful to use large elastic bands to hold the

two shoes in place. A spring removal tool (not A7 specific) is

availble from most motor suppliers, or from eBay for under £5.

Peter Trebilco DA7C

After

relining brake shoes it can be quite a fiddle fitting them once more

with the springs connecting the shoes together behind the hubs. For

older Sevens itís usual to remove the hub but that shouldnít be

necessary for the later Girling brakes aided by the springs with a

little loop at each end into which a specific tool can be used to pull

the springs or one can use a combination of bullnose pliers and a large

screwdriver. However even then it seems that it would be easier to have

three hand with one holding the shoes in place whilst you try and fit

the springs! Instead itís useful to use large elastic bands to hold the

two shoes in place. A spring removal tool (not A7 specific) is

availble from most motor suppliers, or from eBay for under £5.

Peter Trebilco DA7C