RIST HORN INTERIORS

From an article by Mike Phelan reproduced from the Pre War Austin 7 Club Newsletter of October 1988 with many thanks

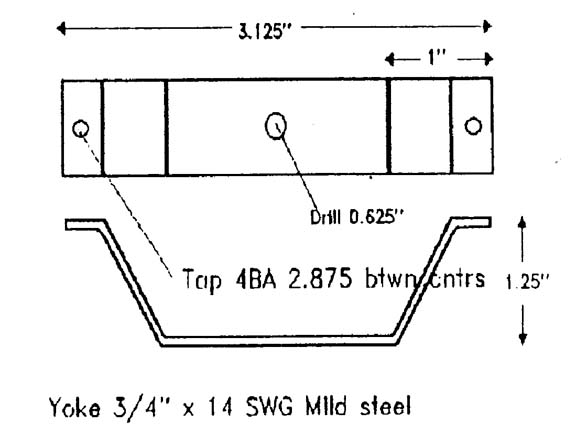

As replacement casings for Rist horns are now readily available, I

thought that a small article on the internal construction and adjustment might

be useful, especially to those

who

are making a new horn to replace one which is completely missing. The

construction is fairly simple and the horn may be made from scrap box materials.

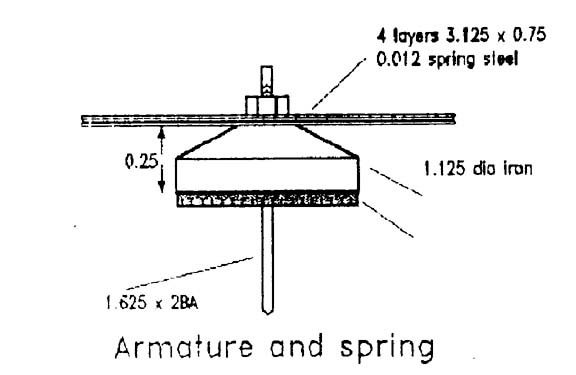

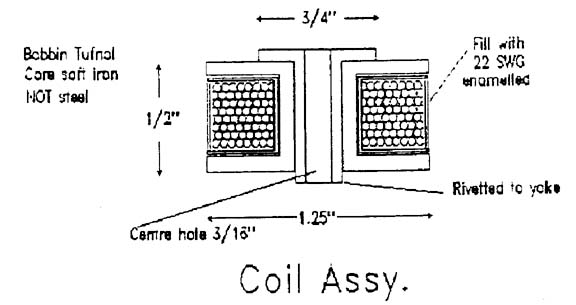

It is important that the coil former and armature are made from soft iron rather

than steel. The latter will eventually develop residual magnetism which will

impair efficiency. The springs can be pieces of old clock spring or hacksaw

blade and it may be necessary to fit more or less than four, depending on the

elasticity of the materials used.

who

are making a new horn to replace one which is completely missing. The

construction is fairly simple and the horn may be made from scrap box materials.

It is important that the coil former and armature are made from soft iron rather

than steel. The latter will eventually develop residual magnetism which will

impair efficiency. The springs can be pieces of old clock spring or hacksaw

blade and it may be necessary to fit more or less than four, depending on the

elasticity of the materials used.

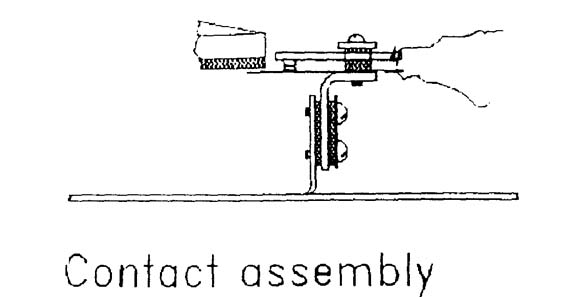

The number of turns on the coil is not critical and the contacts can be any old set of points, relay or cut-out contacts etc. Mild steel can be used for the armature spindle, which can have its top end slotted to ease adjustment. Fit shake-proof washers throughout. The adjustment is rather critical. Horns of this period operate on a different principle to later ones of the thirties. The sound is produced by the armature spindle striking the diaphragm, the trumpet amplifying the sound. Later horns have the armature directly attached to the diaphragm and a tuned steel disc that resonates to one of the harmonics of the vibration frequency.

The diaphragm must be a plain disc of spring steel, free from paint

or dirt, supported between two paper gaskets. The armature must have about 2 mm

movement before the

spindle

contacts the diaphragm. At this point, there should be a gap of 2 - 4 mm between

the fibre disc and the pole face, and the contacts should be just about to open.

Bend the contact bracket for loudest sound. Stuff a rag into the trumpet whilst

testing to make it more bearable for your neighbours! Lock all nuts with paint

when complete.

spindle

contacts the diaphragm. At this point, there should be a gap of 2 - 4 mm between

the fibre disc and the pole face, and the contacts should be just about to open.

Bend the contact bracket for loudest sound. Stuff a rag into the trumpet whilst

testing to make it more bearable for your neighbours! Lock all nuts with paint

when complete.

Mike

Phelan

Mike

Phelan