RESTORING THE OIL PUMP

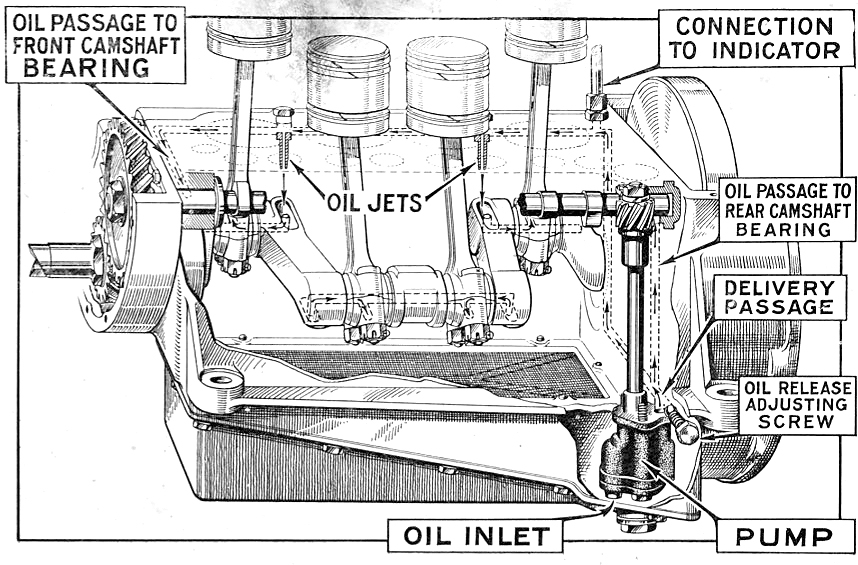

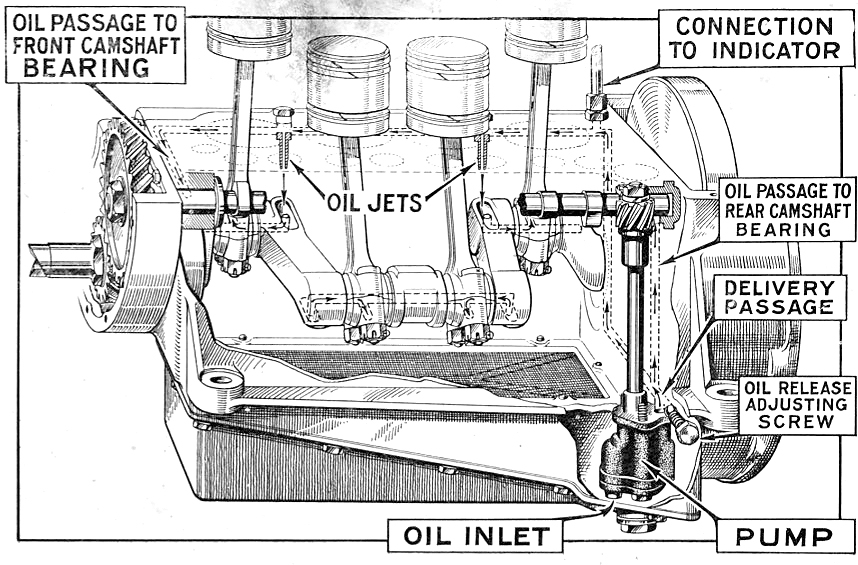

The oil pump is a simple two vane

affair which quietly sits in the corner of the sump, driven from a gear on the

rear of the camshaft. The driven spindle is off-set within the body and the two

vanes are held in contact with the pump body by springs. As the pump rotates the

vanes slide backwards and forwards collecting oil from the sump and delivering

it to the engine oil galleries.

These pumps go on doing their job for years with little attention. However wear does take place due to the many gallons of dirty oil passing through them and their efficiency can be affected. Wear takes place in three areas. The internal bore of the pump gets scored along with the vanes, and the base plate gets worn away. This wear allows oil to escape past the vanes resulting in lower pressure.

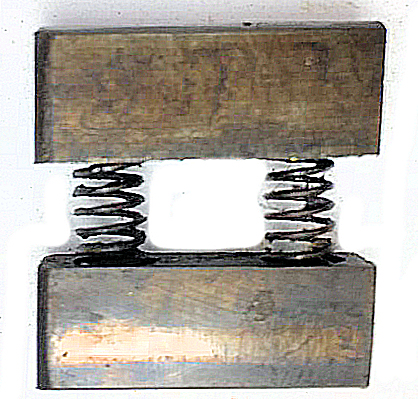

Fortunately they can usually be

reconditioned. The internal bore of the pump can be skimmed. This does not only

clean up the bore it also increases the capacity of the pump, a trick commonly

used in race engines. Removing .030” normally cleans the bore. It is possible to

take a little more but be careful or you could break into one of the fixing

screw holes. Dressing the vanes to remove scoring is more difficult but can be

done by careful use of a stone or emery paper on a flat surface. It is important

to keep the stoned face square with the end of the vane. Finally reface the base

plate by lapping it on a known flat surface. When reassembling the pump use new

springs. An important measurement is the clearance between the base plate and

the pump spindle. This should not exceed .002”. Adjust by either shortening the

spindle or the pump body as appropriate. And finally when fitting the vanes the

curved ends go in first, the flat ends against the base plate. (putting these in

the wrong way round can result in no pressure). If you grease the vanes during

assembly, the pump will prime much quicker.

What pressure can you expect? This will depend on several things - temperature, grade of oil, engine speed , jet size, losses within the engine and setting of the oil relief valve. But for guidance, the following might give you some idea of what to expect. Don't forget this is a splash fed engine and flow is more important than pressure. The same pump is fitted to all Austin Seven pressure-fed engines and if in good condition will maintain 40lbs at high speed.

Standard 2-bearing

splash-fed engine.

With a standard pump and 30 grade or 20/50 oil:

800 rpm tick over

cold 10+ lbs., hot 2 - 3 lbs.

2000 rpm / 30 mph

hot 5 - 6 lbs

Some other things to check when assembling the engine which can affect oil pressure:

Seating of gasket between pump and

crankcase.

Leakage from internal gallery blanking plugs.

Leakage around front camshaft bearing.

Poor seating of oil relief valve ball.

Vince Leek