REPAIRING THE A7 WINDOW WINDER MECHANISM

With a dull click my window disappeared down into the door recess

of my Seven. On all previous occasions there had always been about an inch

showing above the aperture in the door-frame. When I then attempted to wind-up the window to close it the whole

lot speedily descended whilst at the same time the window handle pirouetted

gracefully clockwise. What had gone wrong?

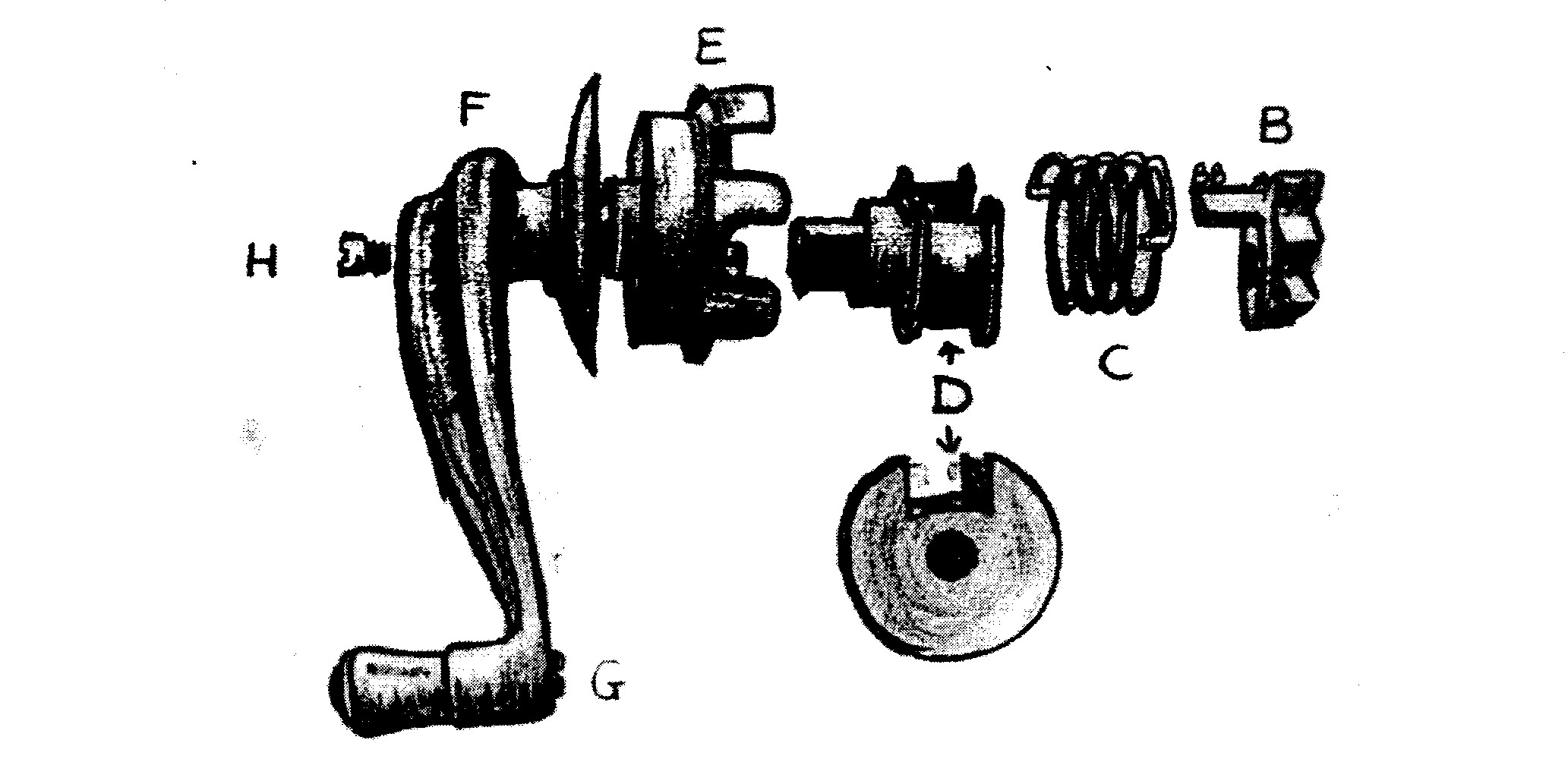

To gain access to the inner workings of the window-winding gear

the door skin has to be removed. This is achieved by removing the handle (F) by

unscrewing the retaining screw (H). Next, release in any order - the door

chain, the handle which is pulled to close the door, the lock mechanism and the

pins which hold the oilcloth covered plywood to the door frame. With a

downwards and outwards pull this will come away from the door and leave exposed

the winding mechanism. In unrestored cars this is the time to notice

deterioration around the bottom edge of the

door. The ply-wood may have woodworm or just senile dementia and it is most

likely that the door skin itself will be in a poor state where it is folded

under to receive the framework for the door.

The mechanism is located on a plate which is held in place by four

screws. In earlier models these are set into captive bolts but in my '37 Pearl

the plate is screwed directly into the woodwork of the door frame. Before

unscrewing these four fixings it is a good idea to mark the relative positions

of the cogs and arms of the mechanism. This will assist with reassembly! Once

released the winding gear can then be lowered making it possible to slide the

two runners out of the channel under the window glass leaving the window itself

still in place.

Next

comes the tricky bit. The drum (E) is attached to the main plate by five lugs

which must very carefully be prized open. Take your time with this operation so

as not to break them off - we are not dealing with a pliable metal.

Once straightened out a few gentle taps on each of them in turn

will disclose the essential inner workings of the mechanism. At this stage

there should be four separate, loose items - the drum (E), the spool (D) with

its spring (C) and a small cog-wheel (B) which has five cogs and a lug

attached. This cog revolves around a spindle (A) which is attached to the

backplate by a rivet. It may be necessary to give the square arm on (E) a

gentle tap to release the spool and spring.

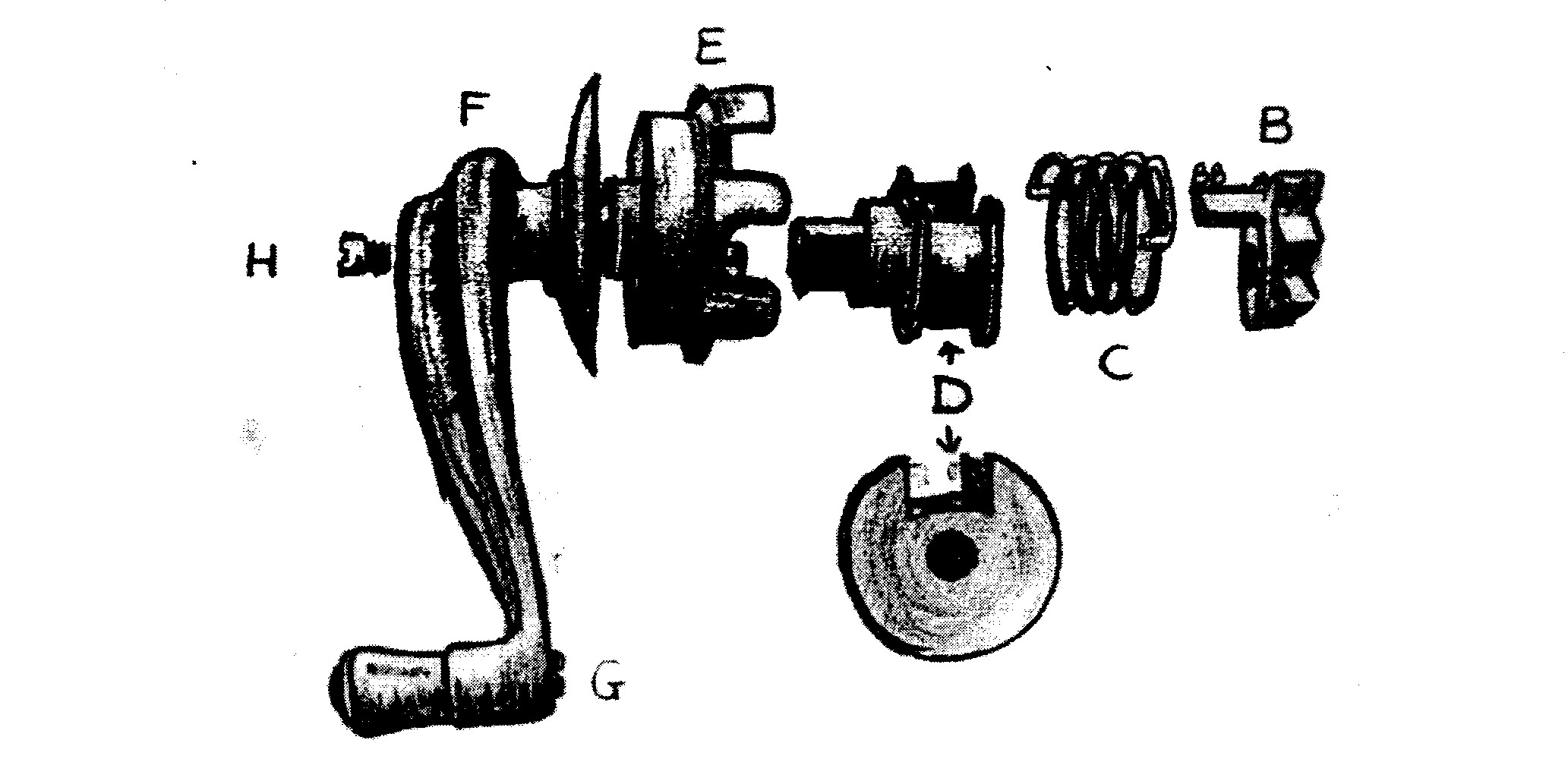

It is the spring (C) which is usually broken. At each end the

spring should be bent inwards at right angles as shown in the diagram (J). It

is one or both of these ends which will be found to have broken. The lug on (B)

presses on these parts of the spring when the weight of the window is received

by it through the cogs and this has the effect of opening out the coiled

spring. This in turn jambs the spring, like a brake shoe, against the inside of

the drum (E). However, when the handle (F) is employed, the spring tends to get

wound up, thus reducing its diameter allowing the spool to revolve inside the

drum to enable the operator to raise or lower the window.

Bart

Walsh, EA7C

This article first appeared in CHASSIS,

Magazine of the Essex A7C