A DA7C Beginner’s Guide

TOOL

TO ASSIST REAR HUB REMOVAL

One of the most important jobs on

a well-used Seven is to keep the rear hubs firmly fixed to the half-shafts. Now

the delight of working on an A7 is that you really don’t need a vast array of

specialist tools - generally only a hammer and, if that doesn’t work, then a

bigger one! However, the odd gadget helps. For the rear hub, you pretty well

must have an A7 hub-puller - make sure its screwed well down onto the hub and

tightened firmly, then hit with the above. But, before you do that, you have to

get the half-shaft nut off - now this is where ‘the gadget’ comes in! You’ve got your big spanner on the half-shaft nut but of course you have to stop

the hub rotating. Often used are mates with a big Stilson on the hub (urgh!) or

stout lengths of wood or metal jammed between the wheel stubs and the hub with

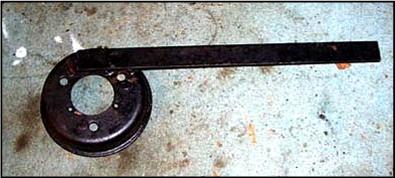

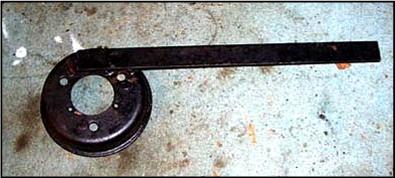

the free-end jammed against the floor. A kinder way is to take an old brake-drum

and weld a thickish metal bar about an inch or so wide and 20 inches long

(nothing critical) to its face leaving the stud-holes clear - preferably use an

old tin drum leaving the rarer cast ones for we who like hydraulic brakes! Once

you have this beauty, hey presto, it immediately replaces the mates, Stilsons,

bits of wood and scraped knuckles in the above procedure - just bolt it on like

a regular brake-drum and tighten or loosen the half-shaft nut to your hearts

content! On tightening- several things. The real engineers will lap the hub onto

the half-shaft taper (obviously without the key) -

You’ve got your big spanner on the half-shaft nut but of course you have to stop

the hub rotating. Often used are mates with a big Stilson on the hub (urgh!) or

stout lengths of wood or metal jammed between the wheel stubs and the hub with

the free-end jammed against the floor. A kinder way is to take an old brake-drum

and weld a thickish metal bar about an inch or so wide and 20 inches long

(nothing critical) to its face leaving the stud-holes clear - preferably use an

old tin drum leaving the rarer cast ones for we who like hydraulic brakes! Once

you have this beauty, hey presto, it immediately replaces the mates, Stilsons,

bits of wood and scraped knuckles in the above procedure - just bolt it on like

a regular brake-drum and tighten or loosen the half-shaft nut to your hearts

content! On tightening- several things. The real engineers will lap the hub onto

the half-shaft taper (obviously without the key) -

not

too strenuously as it will eventually go too far in! Then assemble with the key

and check with ‘engineers blue’ that the tapers are in contact and not held

apart by the key. If the latter, file the top of the key until blissful mating

is achieved! - the hub is supposed to connect to the half-shaft through the

taper and not the key. If you don’t do this, or the nut not fully tightened,

hard use will result in the half-shaft keyway breaking apart with consequent

loss of drive and a significant reduction in your bank balance! Finally, on the

issue of how tight is tight? I asked this self-same question to Vince (who knows

everything!) whilst checking my nuts (actually ‘Rhubarb’s’) after an especially

rough section of the Gibraltar Run - his response was to leap up on the very

long spanner I had in place and jump up and down: ‘that’s how tight’ he said!

You do of course have to line up the split pin hole which might require

different thickness washers.

not

too strenuously as it will eventually go too far in! Then assemble with the key

and check with ‘engineers blue’ that the tapers are in contact and not held

apart by the key. If the latter, file the top of the key until blissful mating

is achieved! - the hub is supposed to connect to the half-shaft through the

taper and not the key. If you don’t do this, or the nut not fully tightened,

hard use will result in the half-shaft keyway breaking apart with consequent

loss of drive and a significant reduction in your bank balance! Finally, on the

issue of how tight is tight? I asked this self-same question to Vince (who knows

everything!) whilst checking my nuts (actually ‘Rhubarb’s’) after an especially

rough section of the Gibraltar Run - his response was to leap up on the very

long spanner I had in place and jump up and down: ‘that’s how tight’ he said!

You do of course have to line up the split pin hole which might require

different thickness washers.

Ian

Mason-Smith

You’ve got your big spanner on the half-shaft nut but of course you have to stop

the hub rotating. Often used are mates with a big Stilson on the hub (urgh!) or

stout lengths of wood or metal jammed between the wheel stubs and the hub with

the free-end jammed against the floor. A kinder way is to take an old brake-drum

and weld a thickish metal bar about an inch or so wide and 20 inches long

(nothing critical) to its face leaving the stud-holes clear - preferably use an

old tin drum leaving the rarer cast ones for we who like hydraulic brakes! Once

you have this beauty, hey presto, it immediately replaces the mates, Stilsons,

bits of wood and scraped knuckles in the above procedure - just bolt it on like

a regular brake-drum and tighten or loosen the half-shaft nut to your hearts

content! On tightening- several things. The real engineers will lap the hub onto

the half-shaft taper (obviously without the key) -

You’ve got your big spanner on the half-shaft nut but of course you have to stop

the hub rotating. Often used are mates with a big Stilson on the hub (urgh!) or

stout lengths of wood or metal jammed between the wheel stubs and the hub with

the free-end jammed against the floor. A kinder way is to take an old brake-drum

and weld a thickish metal bar about an inch or so wide and 20 inches long

(nothing critical) to its face leaving the stud-holes clear - preferably use an

old tin drum leaving the rarer cast ones for we who like hydraulic brakes! Once

you have this beauty, hey presto, it immediately replaces the mates, Stilsons,

bits of wood and scraped knuckles in the above procedure - just bolt it on like

a regular brake-drum and tighten or loosen the half-shaft nut to your hearts

content! On tightening- several things. The real engineers will lap the hub onto

the half-shaft taper (obviously without the key) -

not

too strenuously as it will eventually go too far in! Then assemble with the key

and check with ‘engineers blue’ that the tapers are in contact and not held

apart by the key. If the latter, file the top of the key until blissful mating

is achieved! - the hub is supposed to connect to the half-shaft through the

taper and not the key. If you don’t do this, or the nut not fully tightened,

hard use will result in the half-shaft keyway breaking apart with consequent

loss of drive and a significant reduction in your bank balance! Finally, on the

issue of how tight is tight? I asked this self-same question to Vince (who knows

everything!) whilst checking my nuts (actually ‘Rhubarb’s’) after an especially

rough section of the Gibraltar Run - his response was to leap up on the very

long spanner I had in place and jump up and down: ‘that’s how tight’ he said!

You do of course have to line up the split pin hole which might require

different thickness washers.

not

too strenuously as it will eventually go too far in! Then assemble with the key

and check with ‘engineers blue’ that the tapers are in contact and not held

apart by the key. If the latter, file the top of the key until blissful mating

is achieved! - the hub is supposed to connect to the half-shaft through the

taper and not the key. If you don’t do this, or the nut not fully tightened,

hard use will result in the half-shaft keyway breaking apart with consequent

loss of drive and a significant reduction in your bank balance! Finally, on the

issue of how tight is tight? I asked this self-same question to Vince (who knows

everything!) whilst checking my nuts (actually ‘Rhubarb’s’) after an especially

rough section of the Gibraltar Run - his response was to leap up on the very

long spanner I had in place and jump up and down: ‘that’s how tight’ he said!

You do of course have to line up the split pin hole which might require

different thickness washers.