THE PNEUMATIC WINDSCREEN

WIPER

(The following article was first

published in the Magazine of The Vintage Austin Register and our thanks go to

its Editor, and of course the author Jim Stringer)

Additional dismantling notes by

Douglas Alderson, DA7C at the bottom of the page

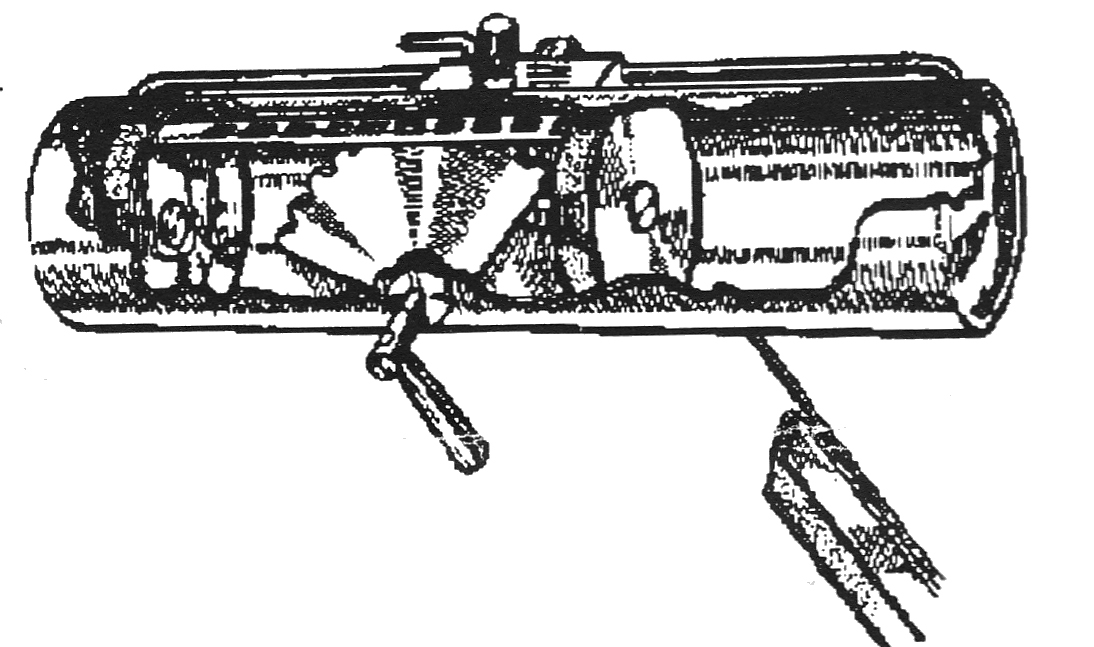

The automatic windscreen wiper was first introduced onto

Austin Motor vehicles in the October of 1924. The device was manufactured by

Joseph Lucas of Birmingham and was operated by the vacuum created via the inlet

stroke of the engine carried through a length of small bore tube connected to

the inlet manifold.

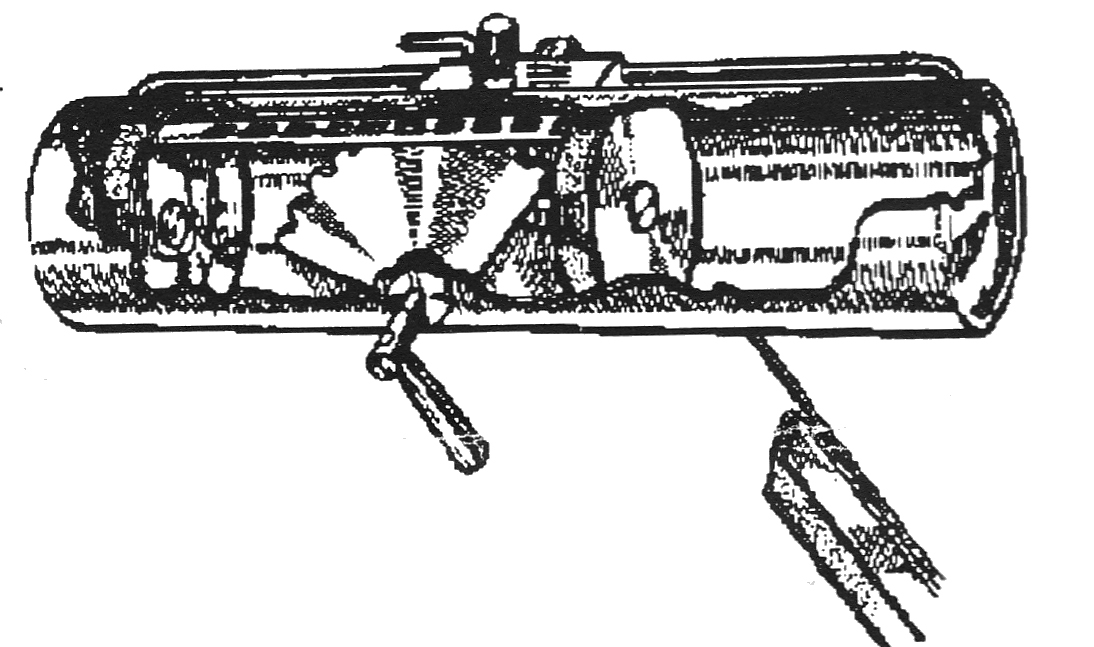

The device is operated by first unscrewing the suction control screw, this

allows the air which is in one of the cylinders to be withdrawn, the resultant

suction moves the rack which operates the wiper arm via the sector wheel or

pinion. When the rack reaches the end of its travel a slide valve is tripped and

the air is sucked from the opposite cylinder and the rack returns. The space

between the two leather washers is always maintained at atmospheric pressure

(otherwise the thing wouldn't move!)

A small lever is provided to allow the device to be operated by hand whenever

there is insufficient vacuum to operate it mechanically.

Although the device worked quite well, it did have a couple of drawbacks. One,

the dropping of the wiper arm directly in front of the driverís line of vision

when it was switched off. This was subsequently rectified in 1930 when a special

valve mechanism, operated by a small slide situated behind the adjusting screw,

was introduced.

The other draw back concerned the inability of the motor to operate at ful l

efficiency when the engine was being accelerated and the amount of vacuum was

significantly reduced - perhaps this may have been viewed as a good deterrent

against driving too fast in the rain!

l

efficiency when the engine was being accelerated and the amount of vacuum was

significantly reduced - perhaps this may have been viewed as a good deterrent

against driving too fast in the rain!

The vacuum wiper therefore only enjoyed a relatively short period of popularity

until it was superseded by electrically operated ones. Ford, however, persevered

and were using pneumatic wipers into the fifties, but by then had installed a

small air reservoir to overcome the problems.

It is of course a requirement for the MOT that, if fitted, the wiper motor must

work. If it doesn't, ≠take it off if you have a car with a split screen which

will give you adequate forward vision. For later cars, such as the Box or

Ruby models, this won't apply.

Generally speaking, there is very little to go wrong

with a vacuum wiper and they

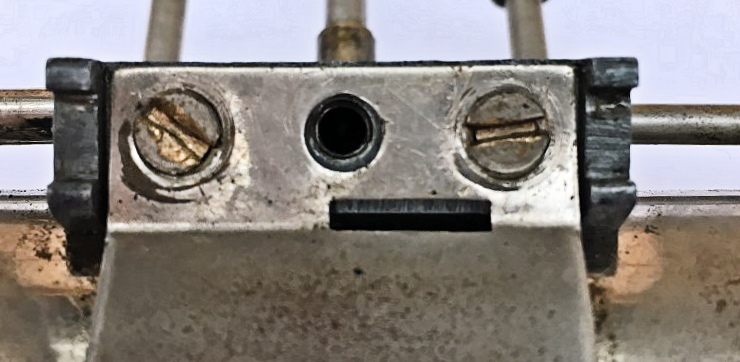

seldom give trouble. A small hole is provided (in

the most inaccessible position) on the top of the unit for the occasional few

drops of oil. How often, I wonder, does this hole ever get used?

seldom give trouble. A small hole is provided (in

the most inaccessible position) on the top of the unit for the occasional few

drops of oil. How often, I wonder, does this hole ever get used?

If your wiper does ever fail, it is a simple matter to remove it and strip it

down to its component parts to affect a repair.

To

remove the unit, first take off the wiper blade which is secured by a

collet-type hexagonal screw. Once removed, two smaller screws will be revealed

which actually hold the unit onto the screen. Finally, remove the rubber tube

which is connected to a pipe at the top of the unit. Once stripped, clean all

the bits carefully in clean paraffin using a cheap artists paint brush. If your

unit has not received any attention for several years, the chances are that the

washers will be dry and hard, making them pretty useless (Obviously they need to

be soft and supple to create the best seal possible within the wiper body).

However, if the washers still appear to be 'sound' they can be revived by an

overnight soaking in linseed oil, which can be gently eased into the surface

until totally saturated. Originally this was achieved by a substance called

Russian Tallow which of course you could still use, if you could find any!

To

remove the unit, first take off the wiper blade which is secured by a

collet-type hexagonal screw. Once removed, two smaller screws will be revealed

which actually hold the unit onto the screen. Finally, remove the rubber tube

which is connected to a pipe at the top of the unit. Once stripped, clean all

the bits carefully in clean paraffin using a cheap artists paint brush. If your

unit has not received any attention for several years, the chances are that the

washers will be dry and hard, making them pretty useless (Obviously they need to

be soft and supple to create the best seal possible within the wiper body).

However, if the washers still appear to be 'sound' they can be revived by an

overnight soaking in linseed oil, which can be gently eased into the surface

until totally saturated. Originally this was achieved by a substance called

Russian Tallow which of course you could still use, if you could find any!

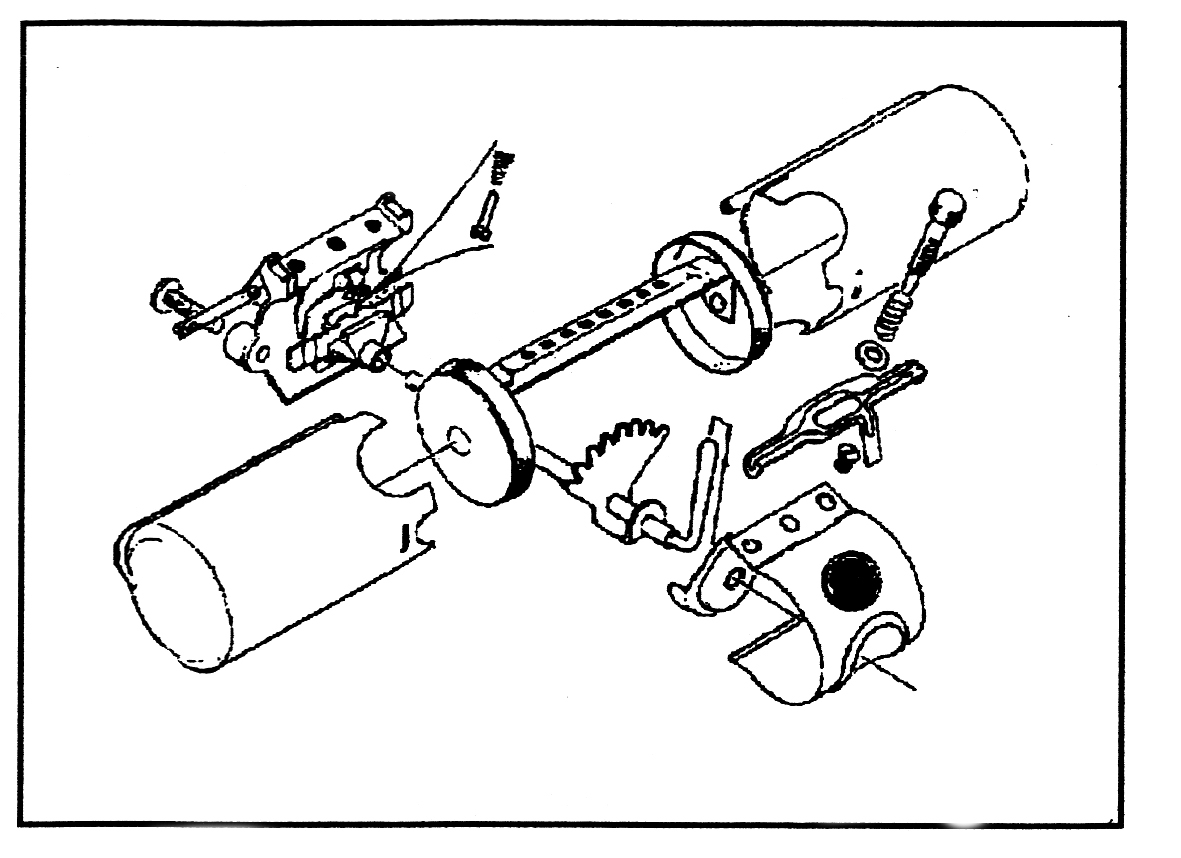

If the 13/8 inch washers are beyond redemption you may be able to obtain

replacements from a hardware shop. If you have to fit new washers carefully

remove the rivets holding them and then carefully rivet the new ones in their

place. If riveting causes a problem, you could use small nuts and bolts, but

remember that any small protrusions will interfere with the smooth operation of

the unit. Thoroughly inspect all components for wear and tear. Other than the

washers, the only bar to the unit behaving satisfactorily will probably be

accumulated dirt and congealed grease, or more likely, a perished rubber hose to

the inlet manifold (which can be supplied by John Barlow and The Seven Workshop

amongst others)

Check that the slide valve operates smoothly and that the pipe connections are

free from any blockages. Check that the teeth on the 'pinion' mesh smoothly with

the slots on the 'rack' and that the shaft onto which the arm is located is not

bent.

When you are satisfied that all are in good working order, grease the two halves

of the barrel with a thin smear of Vaseline and check that the 'rack' with the

washers attached runs through them smoothly but with a slight resistance.

Reassembly is the reverse of the stripping down

procedure - so it will pay you to make a note of how you took it apart! Refit

the motor to the screen and reconnect to the tubing from the manifold, and - Hey

Presto!

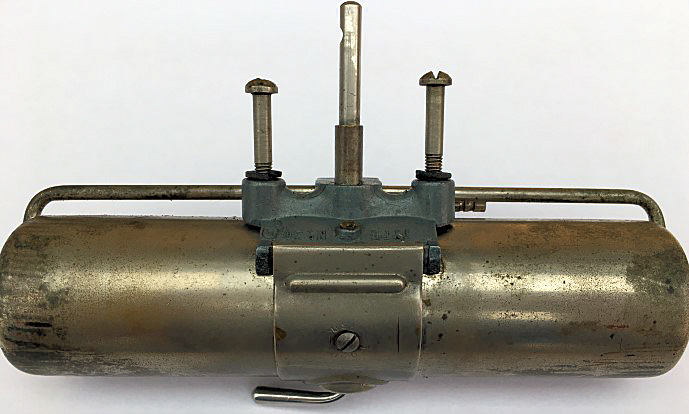

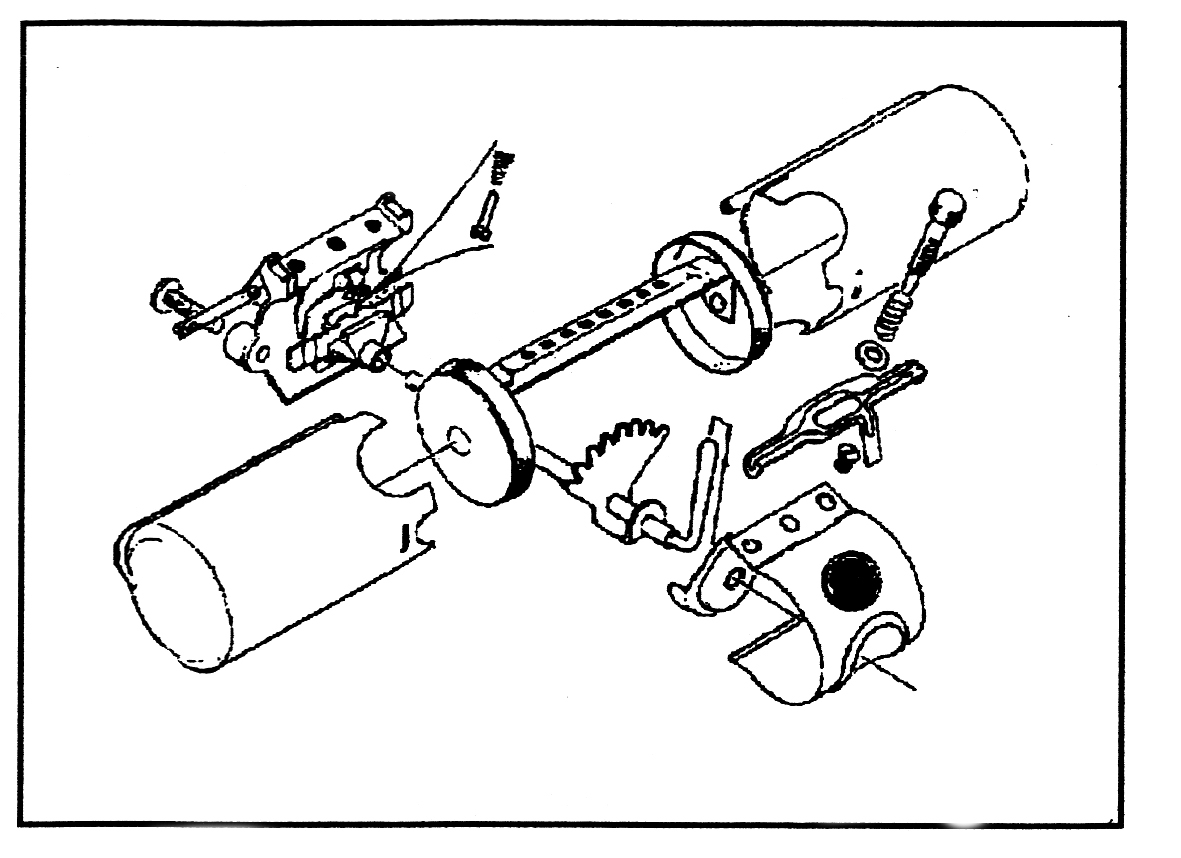

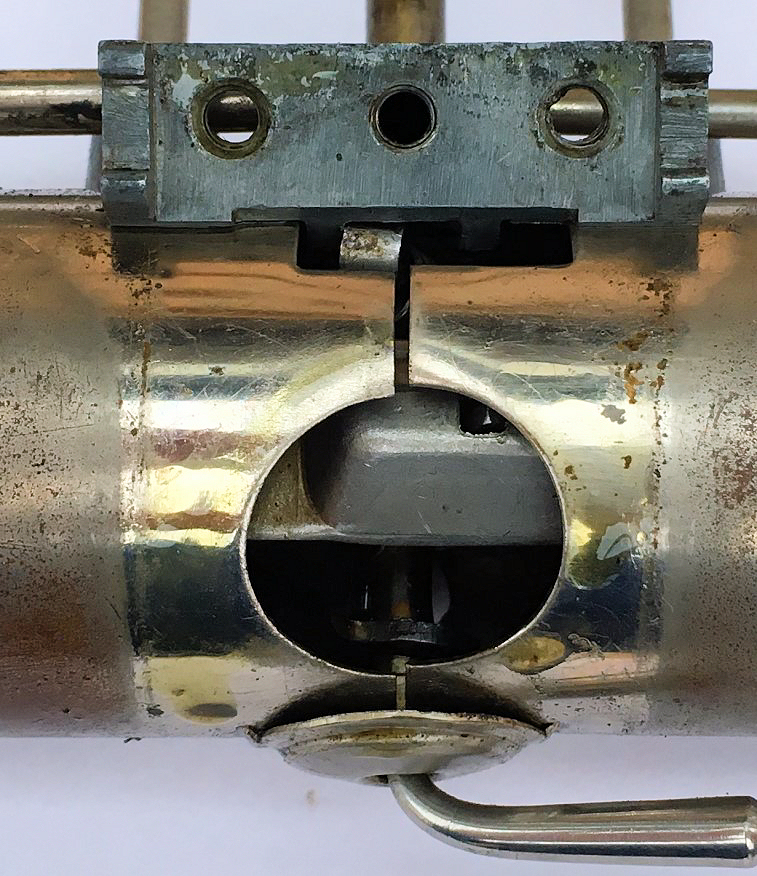

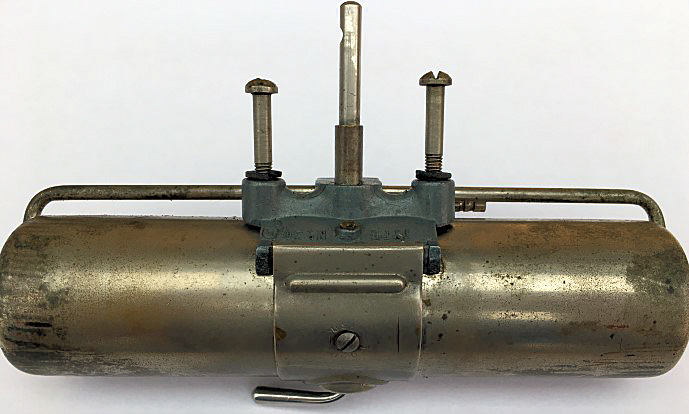

Strip down of motor.

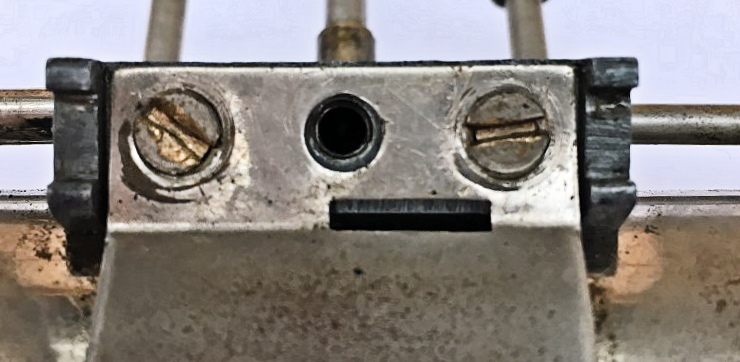

Remove the adjusting screw and cover to reveal 2

screws holding the cover.

Unclip the cover then unclip the

cover around the lever.

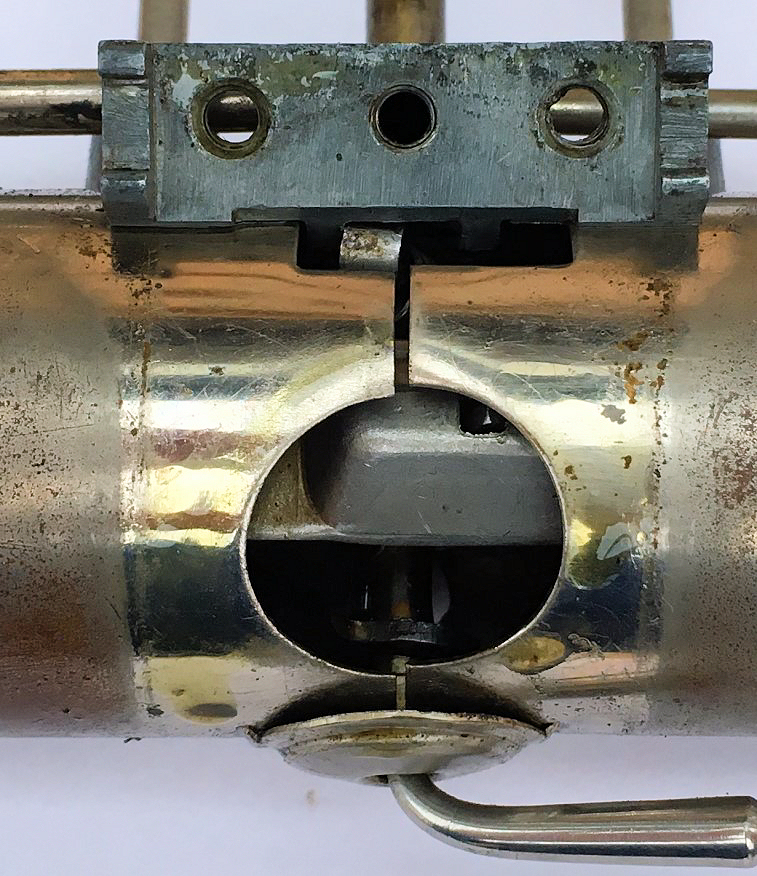

Slide off the body of the wiper to

reveal the leather washer and the rivet holding it in place.

Slide

off the other half of the body, at this stage the rack will probably fall off.

But before it does, make a mental note which way it goes. In the photo,

right, the lever/pinion has rotated 180 degrees, for the rack to fit on the

pinion

Slide

off the other half of the body, at this stage the rack will probably fall off.

But before it does, make a mental note which way it goes. In the photo,

right, the lever/pinion has rotated 180 degrees, for the rack to fit on the

pinion

The

shaft for the wiper arm can be withdrawn from the mechanism, but be careful as

the shaft may be bent and get stuck. The main mechanical part is very easily

damaged or threads damaged so take care not to force anything.

The

shaft for the wiper arm can be withdrawn from the mechanism, but be careful as

the shaft may be bent and get stuck. The main mechanical part is very easily

damaged or threads damaged so take care not to force anything.

The assembly procedure is the reverse but from experience it is a bit of a

fiddle to get the rack and pinion meshing correctly and fit the two halves of

the body. The trick I have found is to fit one body then check the rack/pinon

and then fit the other body.

Douglas Alderson DA7C

l

efficiency when the engine was being accelerated and the amount of vacuum was

significantly reduced - perhaps this may have been viewed as a good deterrent

against driving too fast in the rain!

l

efficiency when the engine was being accelerated and the amount of vacuum was

significantly reduced - perhaps this may have been viewed as a good deterrent

against driving too fast in the rain! seldom give trouble. A small hole is provided (in

the most inaccessible position) on the top of the unit for the occasional few

drops of oil. How often, I wonder, does this hole ever get used?

seldom give trouble. A small hole is provided (in

the most inaccessible position) on the top of the unit for the occasional few

drops of oil. How often, I wonder, does this hole ever get used? To

remove the unit, first take off the wiper blade which is secured by a

collet-type hexagonal screw. Once removed, two smaller screws will be revealed

which actually hold the unit onto the screen. Finally, remove the rubber tube

which is connected to a pipe at the top of the unit. Once stripped, clean all

the bits carefully in clean paraffin using a cheap artists paint brush. If your

unit has not received any attention for several years, the chances are that the

washers will be dry and hard, making them pretty useless (Obviously they need to

be soft and supple to create the best seal possible within the wiper body).

However, if the washers still appear to be 'sound' they can be revived by an

overnight soaking in linseed oil, which can be gently eased into the surface

until totally saturated. Originally this was achieved by a substance called

Russian Tallow which of course you could still use, if you could find any!

To

remove the unit, first take off the wiper blade which is secured by a

collet-type hexagonal screw. Once removed, two smaller screws will be revealed

which actually hold the unit onto the screen. Finally, remove the rubber tube

which is connected to a pipe at the top of the unit. Once stripped, clean all

the bits carefully in clean paraffin using a cheap artists paint brush. If your

unit has not received any attention for several years, the chances are that the

washers will be dry and hard, making them pretty useless (Obviously they need to

be soft and supple to create the best seal possible within the wiper body).

However, if the washers still appear to be 'sound' they can be revived by an

overnight soaking in linseed oil, which can be gently eased into the surface

until totally saturated. Originally this was achieved by a substance called

Russian Tallow which of course you could still use, if you could find any!

Slide

off the other half of the body, at this stage the rack will probably fall off.

But before it does, make a mental note which way it goes. In the photo,

right, the lever/pinion has rotated 180 degrees, for the rack to fit on the

pinion

Slide

off the other half of the body, at this stage the rack will probably fall off.

But before it does, make a mental note which way it goes. In the photo,

right, the lever/pinion has rotated 180 degrees, for the rack to fit on the

pinion The

shaft for the wiper arm can be withdrawn from the mechanism, but be careful as

the shaft may be bent and get stuck. The main mechanical part is very easily

damaged or threads damaged so take care not to force anything.

The

shaft for the wiper arm can be withdrawn from the mechanism, but be careful as

the shaft may be bent and get stuck. The main mechanical part is very easily

damaged or threads damaged so take care not to force anything.