.

.THE PETROL GAUGE

Construction, assembly, faults and remedies

by H Allarton

THE electric petrol gauge is

now practically a universal fitment on all cars and motor cycles, and the

majority of designs are identical in principle, although they may vary in

detail.

There are two units which make up the complete

instrument: one is the glass-fronted gauge on the instrument panel, and the

other the unit mounted in the tank, usually at the top, but occasionally in one

side or end

.

.

The Tank Unit

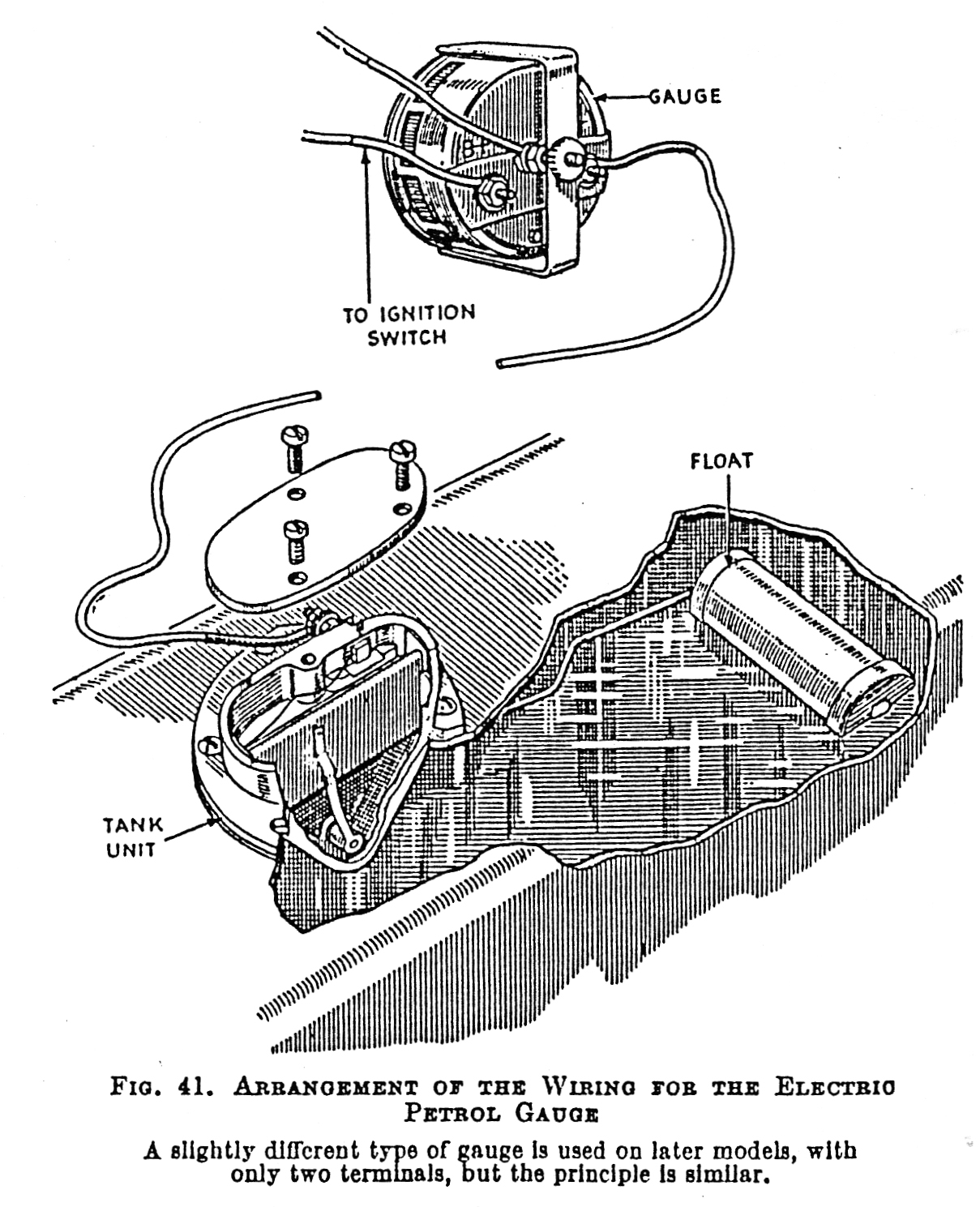

This, as shown in Fig. 1, consists of a float

mounted on the end of an arm which is pivoted on a spindle and arranged so that

vertical movement of the float is transmitted to a second smaller arm which is

in contact with, and moves horizontally over, a length of resistance wire wound

on a former. As the level of petrol in the tank rises or falls so the float does

likewise, and this movement causes the second arm to vary the effective length

of the resistance wire. The resistance wire is connected in series with the

deflecting coil in the gauge unit, as can be seen from the circuit diagram, and

thus the magnetic field emanating from the deflecting coil is made weaker or

stronger, depending upon the amount of resistance in the circuit.

The whole unit is usually mounted in a die-cast

housing which is flanged to fit the tank and which has an inspection cover for

access to the resistance wire and moving contact. The unit usually has only one

terminal which is connected to the gauge on the panel (terminal T), the moving

contact bring earthed to the cam and thus completing the circuit.

The Gauge Unit

These (also shown in Fig. t) naturally vary

considerably in external appearance, since very few can have identically styled

instruments, but they consist in essentials of a pair of coils wound on formers

with soft iron cores. The coils are disposed so that the magnetic fields they

produce, when current is passed through them, influence a soft iron armature

carried on a spindle. Attached to the spindle is a pointer which moves over a

graduated scale. One coil is called the control coil and the connections are so

arranged that the full battery voltage is always applied to this coil when the

ignition switch is on. The other coil is called the deflecting coil, and the

voltage applied to this coil is proportional to the amount of petrol in the

tank, since in series with it is the resistance wire in the tank unit, the

effective length of which is varied by the moving contact which in turn is

operated by the float.

How the System Works

When the petrol tank is full, the float will

have operated the sliding contact on the resistance in the tank so that all the

resistance wire is in circuit. The current flowing through the deflecting coil

will therefore be a minimum and the magnetic field from it will therefore be at

its weakest. On the other hand, the current passing through the control coil

will be a maximum since the full battery voltage is always applied to this coil

when the ignition switch is on. The magnetic field from the control coil will

therefore be very strong, and the soft iron armature will be attracted to its

maximum extent, so that the pointer will indicate " full" on the gauge.

As the level of petrol falls the float will also fall,

causing the moving contact to move over the resistance, thus reducing the amount

in circuit. The current in the deflecting coil will thus increase and there will

be a corresponding increase in the strength of the magnetic field from the

deflecting coil. Since the coils are so arranged that their magnetic influences

on the soft iron armature are in opposition, the armature and therefore the

pointer will be deflected more and more from the "full" position until, with no

petrol in the tank, and therefore no additional resistance in the deflecting

coil circuit, the effects of each coil on the armature cancel each other out and

the needle shows "empty" on the scale.

Tracing Faults

The petrol gauge as described above is

intended solely to give an indication of the amount of fuel in the tank and was

never designed as a means of calculating fuel consumption. Provided that this

fact is remembered, the electric petrol gauge is extremely reliable and will

usually continue to work satisfactorily without attention for many years.

Irregular or false indications when they do occur are usually due to faulty or

loose connections in the wiring; the gauge and tank units will seldom be found

at fault.

Faults can very readily be localised and corrected by

following a simple procedure. Reference to the circuit diagram will be helpful

in tracing the following faults. Figures given are for 12-volt systems.

No Reading

Any open circuit in the control coil

connections will result in no reading at all on the gauge, regardless of the

amount of petrol in the tank and the most likely cause is therefore a broken

connection between the gauge (terminal B) and the ignition switch or between the

ignition switch and the control box. A blown or loose accessories fuse should

not be overlooked in this case.

In the unlikely event of the trouble not being located

at any of the above points, then the control coil in the gauge must be

suspected. To check the coil properly, its resistance should be measured if

suitable equipment is available. The control coil should have a resistance of

the order of 160 ohms.

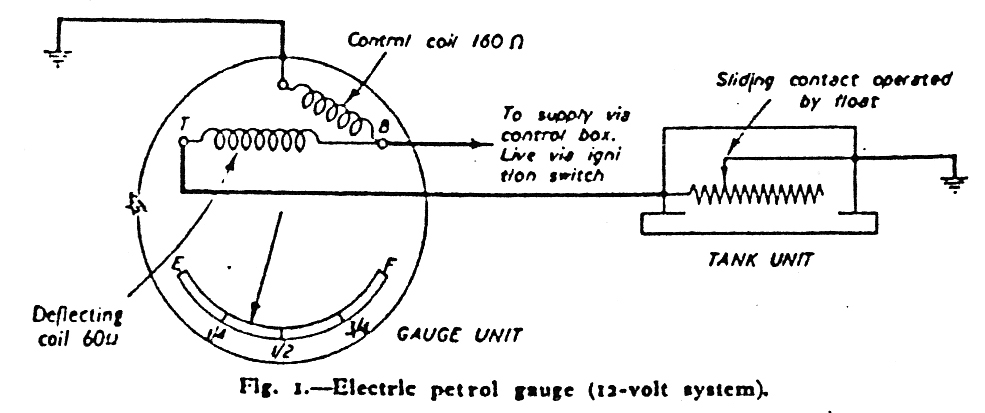

However, a simple test can be made using only a

voltmeter, and this will at least determine whether or not the coil is faulty.

Any fault which may be found will almost certainly be due to a broken connection

or badly soldered joint.

If a voltmeter is connected between the positive

terminal of a 12-volt battery and terminal B on the meter, and the negative

terminal of the battery is connected to the case of the meter, a reading of 12

volts should be shown on the voltmeter if the coil and connections arc sound.

Alternatively, if a milliammeter is available and is connected in series with

the control coil and a 12-volt battery, a reading of 75-80 mA will be obtained

if all is in order (see Fig. 2).

Continuous "Full"

Reading

An open circuit in the deflecting coil

circuit will result in the gauge always showing " full," irrespective of the

amount of petrol in the tank. Points to check in this case are:

(1) the wire between terminal T on the

gauge unit and the single terminal on the tank unit;

(2) the earthing connection of the tank

unit;

(3) the sliding contact which moves over

the resistance wire.

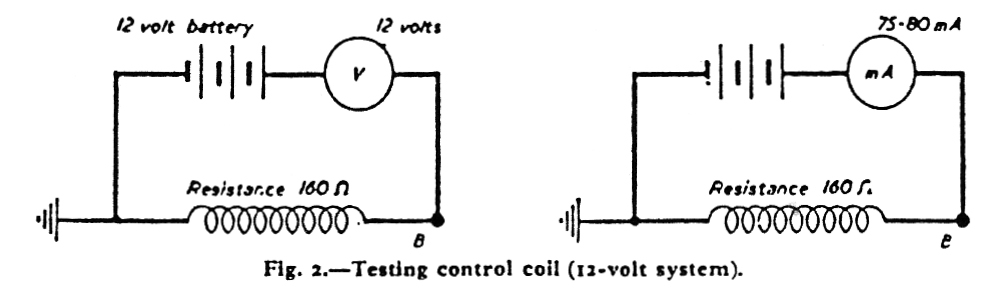

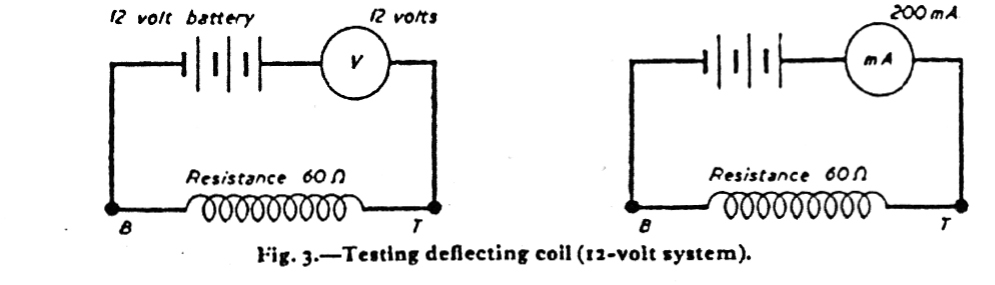

If all these are proved sound, then the deflecting

coil in the gauge unit must be checked in the same manner as the control coil.

Its resistance is approximately 60 ohms, and a 12-volt battery connected

across it will cause a current of 200 rnA to flow (see Fig. 3).

Intermittent Reading

An intermittent reading will usually be found

to be caused by a faulty contact between the sliding contact and the resistance

in the tank unit; in this case the contact arm and the surface of the wire over

which it moves should be cleaned with fine emery paper. Care should be taken to

see that the arm moves freely and is in contact with the wire throughout its

movement.

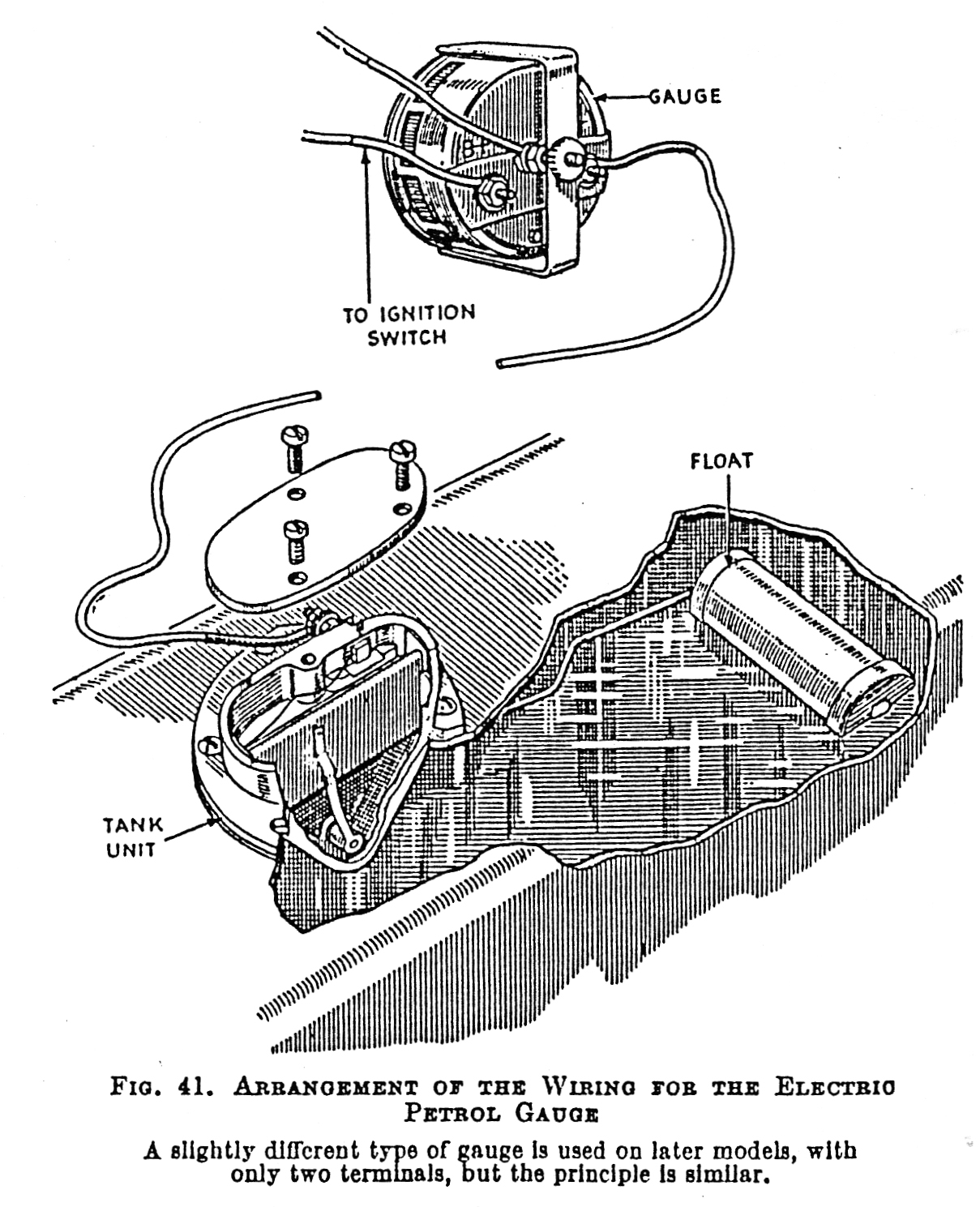

The points at which a loose or broken connexion might

put the gauge out of action will be seen from Fig. 41. It is important that both

the gauge and the tank unit should earth properly. The cable from the tank unit

may be earthing at some point if the gauge shows a full tank without cause. If

it is the tank unit terminal which is earthed, the unit will require repairing.