If you are looking for a

replacement nose cone in good condition you will find that they are becoming

harder to source. Perhaps it’s because this is the item to first “meet

opposition” in a front-end collision! Other problems relate to no longer being

able to latch the starting handle in the horizontal, parked position (perhaps

due to a weak/short spring) or maybe having the wrong nose cone.

Until the de Luxe version of the Ruby appeared, all the standard models had the starting handle secured to its shaft with a cotter. The Ruby, now sporting a bumper bar, continued to have a fixed starting handle, but the associated Tourers (without bumper bars) now had detachable handles locating on a square section at the end of the shaft. A few of the square shafts are to be found in our spares shed, but handles have often become lost over the years and are now quite hard to come by.

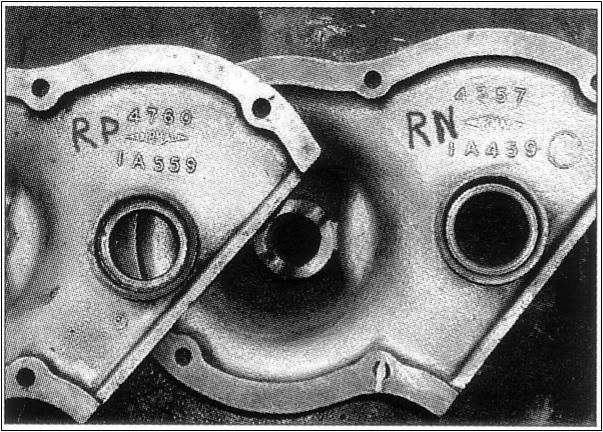

Cars with a three speed gearbox, such as the early RN Saloons, have a nosepiece with an overall length of 7¼" - part number 1A 459. The associated shaft is 7⅞" long - part number BD 202. The later RNs, and the RP Saloons, with the 4 speed gearbox, have their engines mounted further forward and therefore have a shorter nose cone which is 6½" long - part number 1A 559. The shaft, part number, BD219 is 7⅛" long. The earlier items can be fitted into the RP type models with no problem other than sticking out beyond the radiator surround, but, if you are a purist, you will be seeking the shorter one!

One reason for the handle dangling, rather than latching as intended, lies in the wear/breakage of part of the casting inside the nose cone. The required profile can be re-established by careful use of drills and rotary files. If the driving dog at the end of the shaft is worn it should be replaced with a high quality steel. An old big end bolt is an excellent source of material.

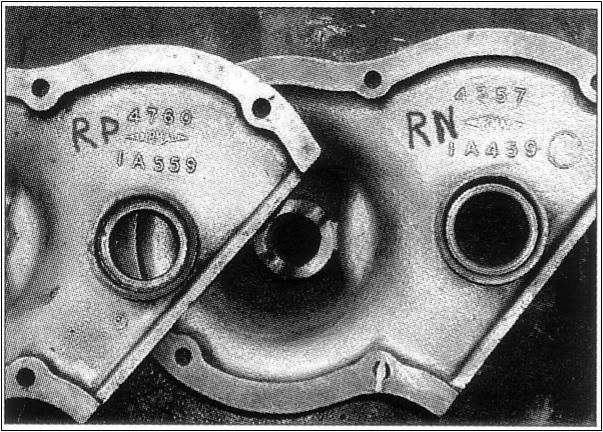

The picture shows what any of

the above mentioned noses looks like if cut through 2" from the joint face. The

13/16" dia. hole can become “worn” from the rattling of the shaft, further

allowing oil/oil mist to enter the outboard area. The small hole is there to

allow drainage back into the sump. If blocked or restricted, oil will drip from the front end, particularly

on long downhill runs. Often this area is full of a thick mixture of oil and

road dirt. When “diving” through a ford, the nose cone may scoop up water and

drop it in the sump. These robust engines will continue to run on this emulsion

but it’s a good idea to check the dip stick ASAP and change the oil at the very

next opportunity. Alternatively, plan ahead with some cling film!!

sump. If blocked or restricted, oil will drip from the front end, particularly

on long downhill runs. Often this area is full of a thick mixture of oil and

road dirt. When “diving” through a ford, the nose cone may scoop up water and

drop it in the sump. These robust engines will continue to run on this emulsion

but it’s a good idea to check the dip stick ASAP and change the oil at the very

next opportunity. Alternatively, plan ahead with some cling film!!

To reduce the gap between the 13/16" dia. hole and the 11/16" dia. of the shaft, and to prevent a problem whereby the spring manages to get up into the timing gear area, a washer with a ¾" hole and approx. 13/16" o/d can be inserted between the inboard end of the spring and its mating face on the nose cone. Two diametrically opposite flats will be needed to allow it to be threaded in from the outside.

In view of the shortage of nose cones, and the ankle-whacking properties of the Ruby type, on any spare engine you may have in store, there’s a lot to be said for having a chopped off nose cone, as seen in the picture, taken from one beyond repair. This one awaits a small plate (to be secured with a couple of self tap screws) plus a capped old dynamo cover, and all the foreign bodies queuing up to enter your prized spare are denied entry (at least by this route)! It is not hard to acquire damaged cones that are beyond repair by even the most skilled machinist and welder. Sometimes they appear in the club spares already suitably chopped and blanked having spent time “in a previous existence” on somebody’s special. All grist for the mill! Ron Hayhurst (With many thanks)