MAGNETO IGNITION EXPLAINED, MAINTENANCE & FAULTFINDING

By G. A. ASHWELL, Service Manager, Globe & Simpson, Ltd

From the MA7C Newsletter 1992 with many thanks

THE magneto, unlike the coil, is a selfcontained unit

and does not have to depend on a current supply from a battery as it generates

its own primary current. This fact is often argued in favour of the magneto as

against coil ignition.

There are three distinct types of high tension magnetos now in use—(1) the

rotating armature and permanent horseshoe magnet type ; (2) the rotating magnet

type with stationary armature; (3) the polar inductor type having stationary

permanent magnets, stationary armature and rotating inductor.

The principles of the armature are the same as for coil ignition. There are two

windings: a primary and secondary, with a condenser located across the contact

breaker points.

How is the Current Induced in the Primary

Winding?

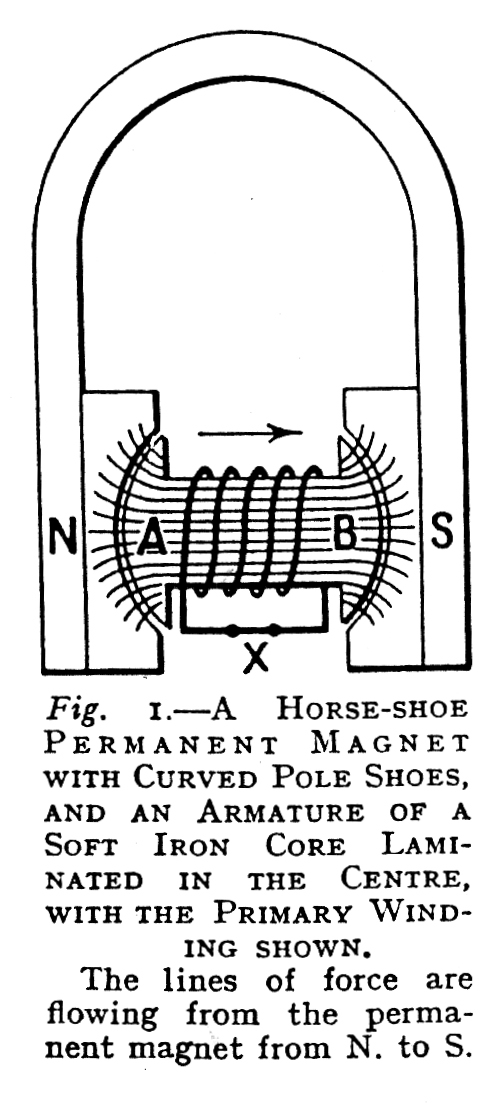

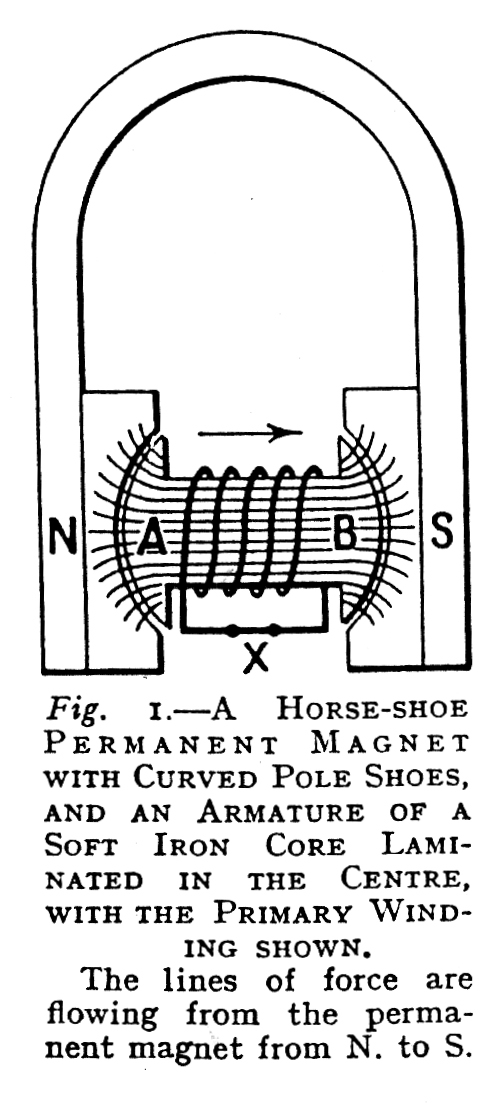

This is brought about by utilising the principle of rotating a loop of

wire in a magnetic field. Fig. 1 shows a horseshoe permanent magnet with curved

pole shoes to conform with the periphery of the rotating armature. The armature

is constructed of a soft iron core laminated in the centre; this core is

thoroughly insulated with oiled silk and Empire cloth. The primary winding is

then wound on.

For the moment, we will only consider what happens in the primary winding.

Referring again to Fig. 1 you will observe that the lines of force are flowing

from the permanent magnet from N. to S. and are concentrated through the

armature core entering at the cheek A and leaving at cheek B. The reason for the

lines of force concentrating through the core is due to the fact that this is

the easiest path, iron being an excellent conductor of magnetic flux. Another

minor point must be borne in mind —that is, the armature cheek marked A becomes

a S pole and cheek B becomes a N pole, the law of magnetism being: like poles

repel, and unlike poles attract.

You will see in Fig. 1 that the primary is embracing the lines of force flowing

through the iron core, therefore to induce a current in the primary winding all

we have to do is to make the winding cut the lines of force. It must be pointed

out at this juncture that the primary circuit is a closed or complete circuit

through the contact breaker X.

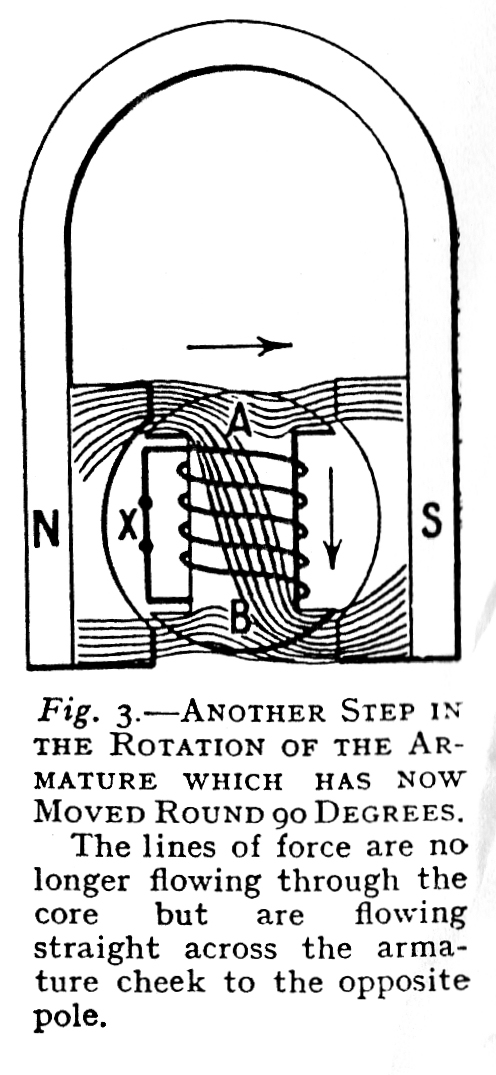

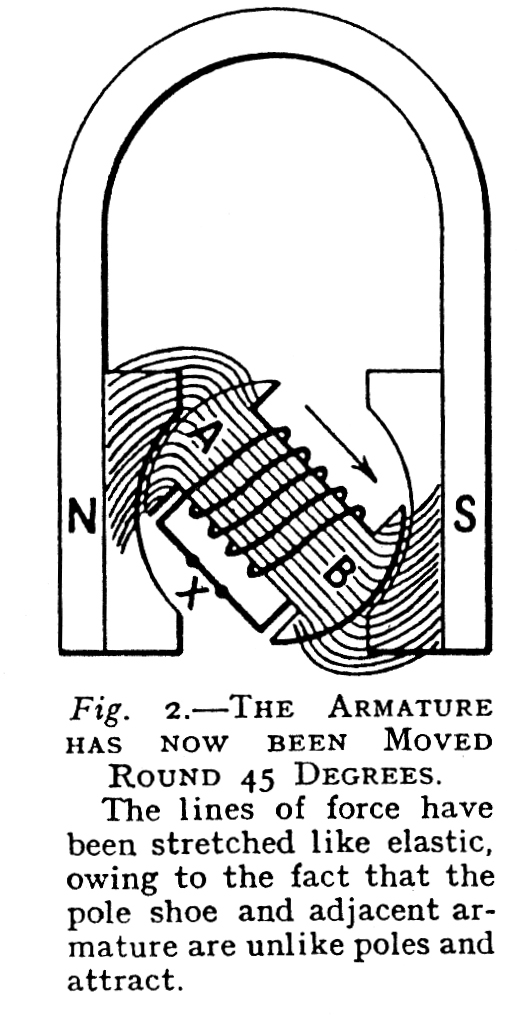

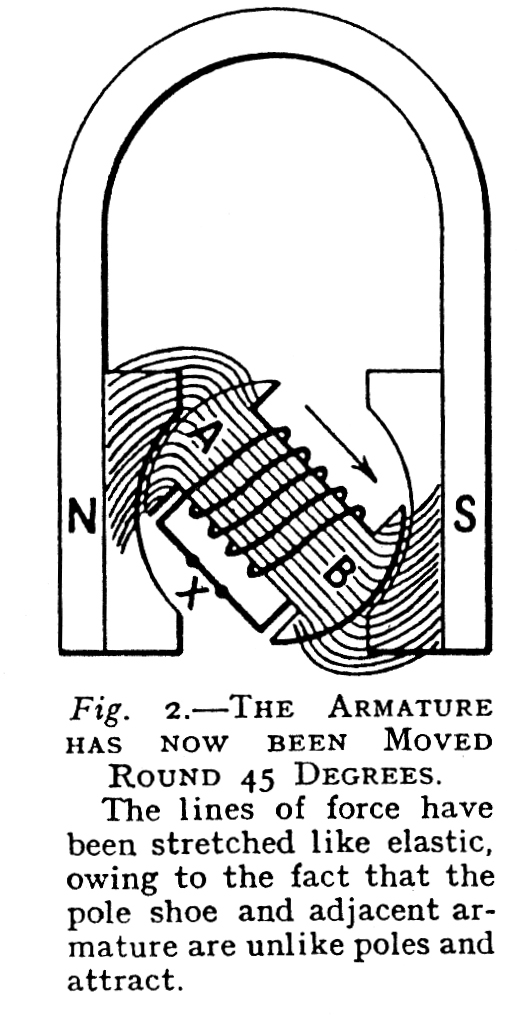

In Fig. 2 the armature has been moved round 45°—this has resulted in the lines

of force being stretched like elastic, owing to the fact that the pole shoe and

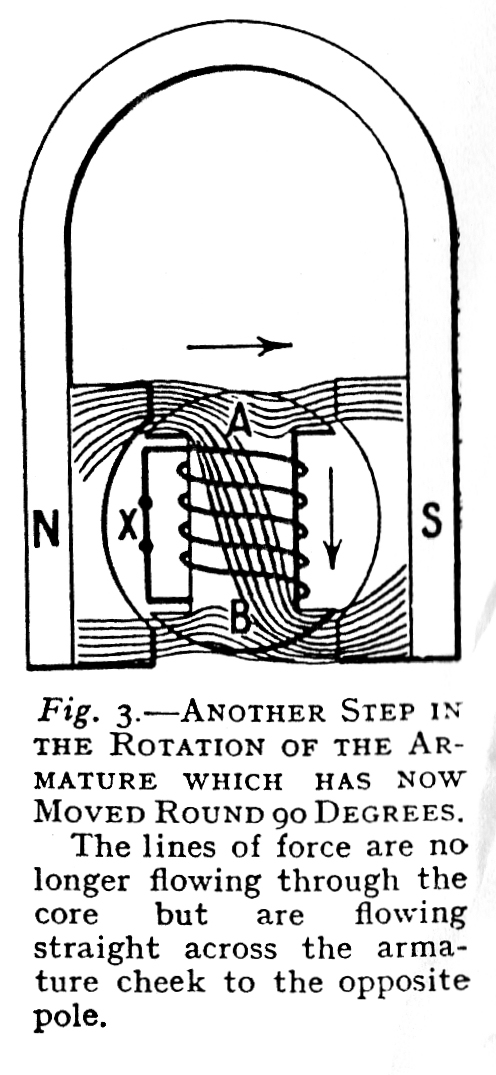

adjacent armature are unlike poles and attract. Fig. 3 shows another step in the

rotation of the armature which has now moved round 90° from the position in Fig.

1. If you now follow the lines of force in Fig. 3 you will see that some of the

lines are no longer flowing through the core but are flowing straight across the

armature cheek to the opposite pole. Therefore, the lines of force passing

through the primary winding have decreased and a current has been induced in the

primary winding. This in turn will tend to strengthen the magnetic flux in the

core and attract the lines of force flowing from the permanent magnets.

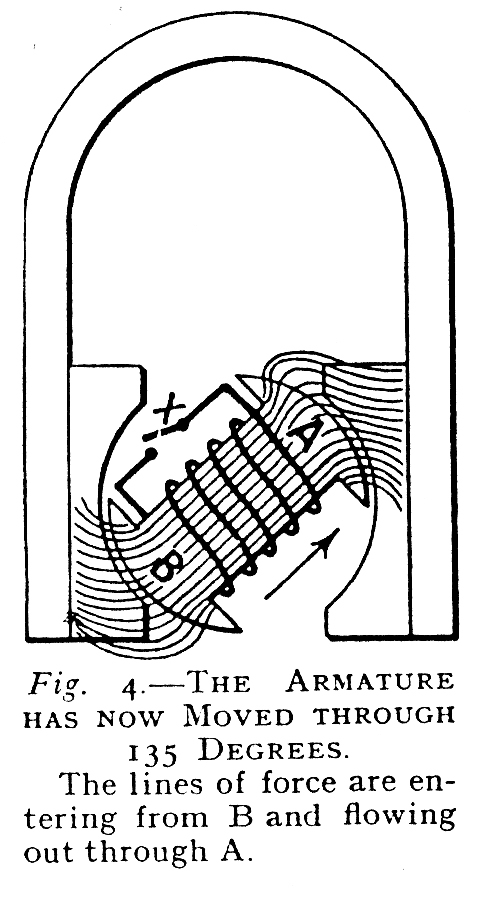

Let us now turn to Fig. 4. The armature has now moved through 135° and a

definite change will be seen to have taken place. The lines of force are now

entering the armature core from the bottom cheek B and are flowing out through

the cheek A, which is in the reverse direction to that in Figs. 1, 2 and 3.

Therefore, the lines of force flowing through or embraced by the primary winding

must have fallen to zero in one direction and started up in the opposite

direction; at the point of change the current in the primary will have reached

its maximum. It has already been pointed out that the greater the rapidity of

the collapse of the lines of force embraced by the primary winding, the greater

will be the voltage induced in the secondary winding.

The Operation of the Contact Breaker.

It is here that the action of the contact breaker comes into the

reckoning, as it will be understood that so long as the points remain closed,

current in the primary winding will be able to flow. This will in turn tend to

produce a magnetic flux in the core which we are endeavouring to decrease with

the utmost rapidity. Therefore, if we break the primary circuit at the precise

moment when the greatest change in flux density is taking place, we shall have

an almost immediate collapse of the lines of force flowing through the armature

core and windings, resulting in a very high induced voltage in the secondary

winding. This is further assisted by the condenser.

When Should the Contact Breaker Points Open?

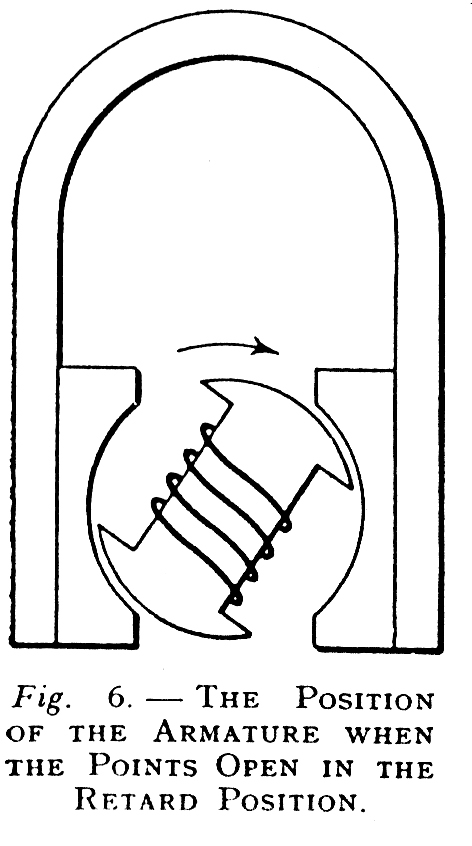

Fig. 5 shows the position of the armature when the contact

breaker points open in the advanced position, and Fig. 6 the position of the armature when the

points open in the retard position.

open in the advanced position, and Fig. 6 the position of the armature when the

points open in the retard position.

What Should be the Distance of the Air Gap?

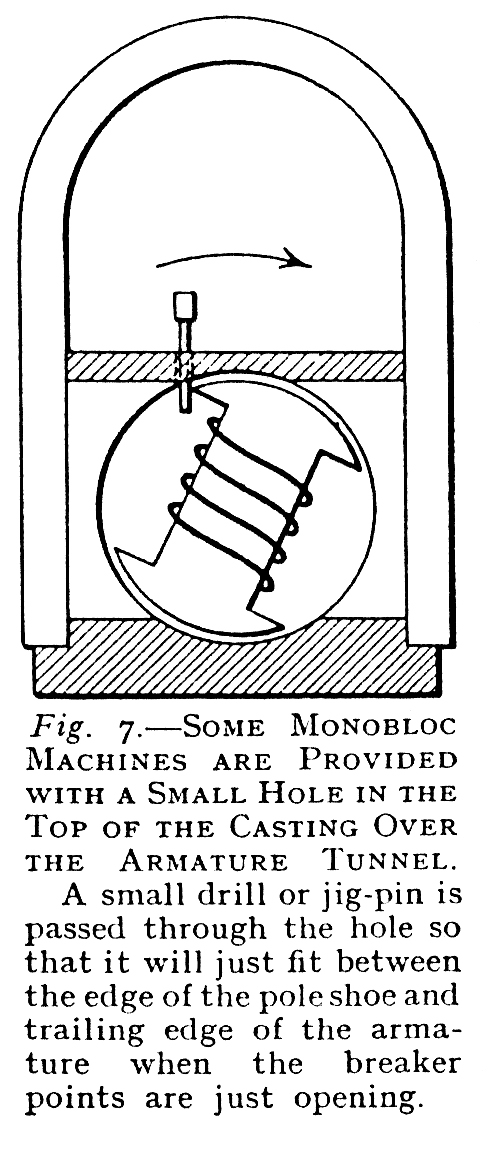

This depends on the type and construction of the pole shoe The modern

tendency is to use laminated pole shoes cast integral with a monobloc casting;

the earlier machines, however, had soft iron or cast iron pole shoes. The air

gap for laminated pole shoes is usually between 0.5 mm. and 1.5 mm; with solid

pole shoes it varies from 2 mm. to 3 mm. Some monobloc machines are provided

with a small hole in the top of the casting over the armature tunnel, through

which a small drill or jigpin may be passed, as in Fig. 7, so that it will just

fit between the edge of pole shoe and trailing edge of armature when the breaker

points are just opening.

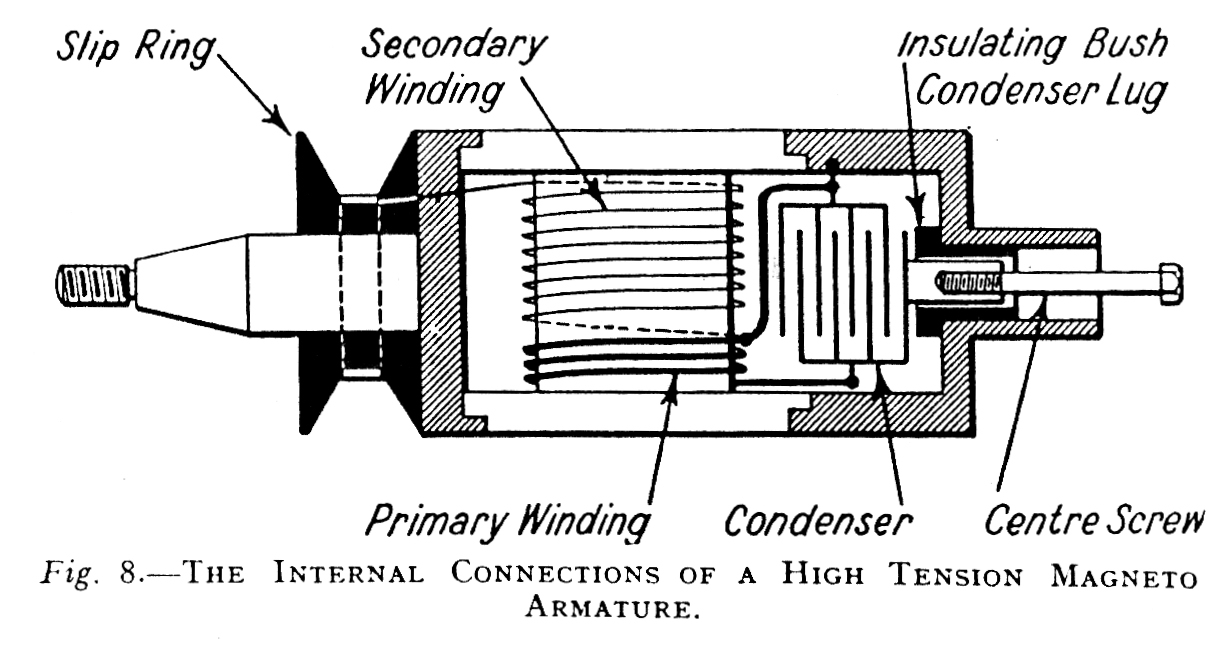

Fig. 8 shows the internal connections of a high tension magneto armature.

What is the Path of the Primary Circuit?

One end of the primary winding is earthed to the armature core either

on the core itself before commencing the winding or at the condenser lug that is

earthed to the end housing by means of a screw; the other end of the primary is

brought out to the insulated side of the condenser and is in circuit with the

lug receiving the centre screw of the contact breaker.

What is the Path of the Secondary Circuit?

One end of the secondary is connected to the primary winding and

consequently goes to earth. The other end is brought out to the slip ring and

conducted by a highly insulated conductor to the distributor.

Distribution of the High Tension Circuit.

The high tension circuit is conducted to the distributor, as already

stated; the conductor, however, is located in a gear wheel and rotates to

distribute the current to the respective plugs in turn.

If we turn back for a moment to Figs.1, 2, 3 and 4, it will be seen that from

Fig.1 to Fig. 4 the armature has completed nearly half a revolution; by

rotating the armature another 45° it will be in a similar position to Fig. 1.

This being so, it will be understood that two sparks per revolution of the

armature can be obtained.

A fourcylinder magneto runs at crankshaft speed but only one spark every second

revolution is required for each cylinder; therefore, the distributor rotor will

need to run at half the speed of the armature to obtain four sparks for one

revolution and so distribute the sparks to the required cylinders in one of the

following sequences—1, 2, 4, 3 or 1,3,4, 2, a spark being required for each half

revolution of the crankshaft.

In a six-cylinder engine, a spark will be required every third of a revolution

of the crankshaft. The magneto will therefore have to run at 1½ times the

crankshaft speed. The distributor rotating arm must run at half the speed of the

crankshaft and fire each cylinder in one of the following sequences—1, 4, 2, 6,

3, 5 or 1, 5, 3, 6, 2, 4.

The Operation of the Cams.

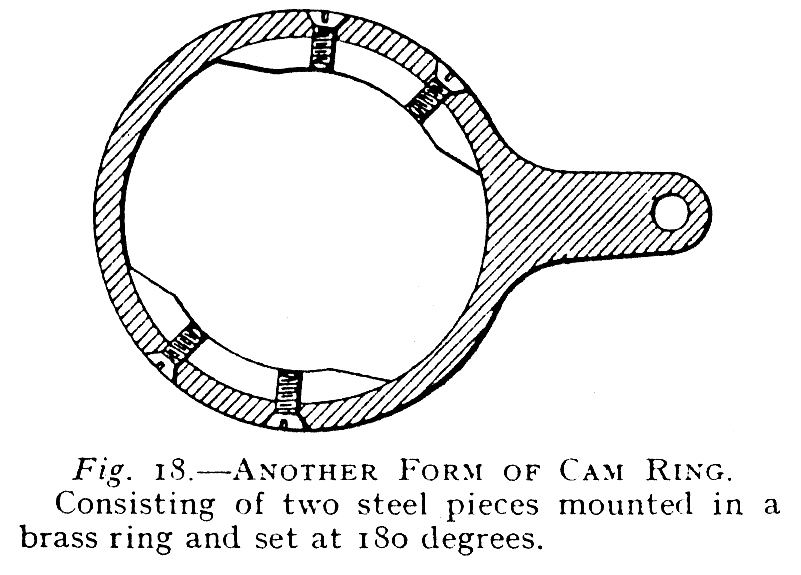

On a two, four or sixcylinder magneto, two cams are arranged to open

the contact breaker at the required moment. The cams may be in the form of a

circular steel ring ground away on two sides, as shown in Fig. 17, or may be two

steel pieces mounted in a brass ring as shown in Fig. 18, and set at 180°.

It is very seldom that cams require renewing, but it is essential to see that

the breaker points open evenly on each cam. In the case of a onepiece cam ring,

it is impossible to make any adjustment to even up the cams should the points

open unevenly. Repairs and adjustments are possible, however, with cams that are

fitted as separate components in a brass cam ring.

To obtain the required amount of advance and retard, the cam is made moveable

over a range of from 15 to 30 degrees, some makes of machines having a greater

range than others. This movement is controlled by a pin or stop screw in the cam

box into which the cam ring fits, the inner lip of the cam ring being cut away

to allow for the required amount of movement.

Modern Pole

Shoe Design.

Modern Pole

Shoe Design.

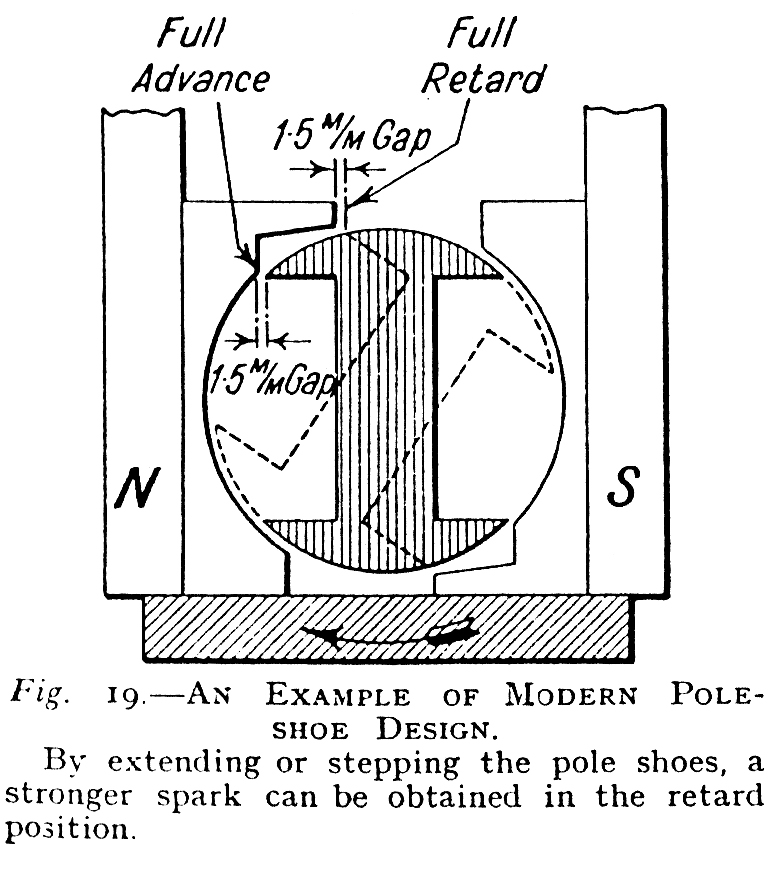

There has been a great advance in pole shoe design in recent years, and

it has been found that by extending or stepping the pole shoes, as in Fig. 19, a

stronger spark can be obtained in the retard position than was possible with the

early type of pole shoe, as shown in Figs. 1, 2, 3 and 4. Another development

has been the construction of laminated pole shoes.

Object of the Extended Pole Shoe.

The object of the extended pole shoe is to delay the reversal of the

flux so that an efficient spark can be obtained in the retarded position for

starting, for it is obvious that when the breaker points open in the retarded

position in a magneto having pole shoes as in Fig. 1, a considerable loss of

magnetic flux will have taken place in the armature core by leaking across the

armature cheek to the opposite pole, therefore when the points open and the

primary collapses the number of lines of force cut or changed in the winding

will be less, resulting in a lower voltage being induced in the secondary

winding. It must be understood that the induced voltage not only depends on the

rapidity of the collapse of the lines of force but also on the quantity

collapsed.

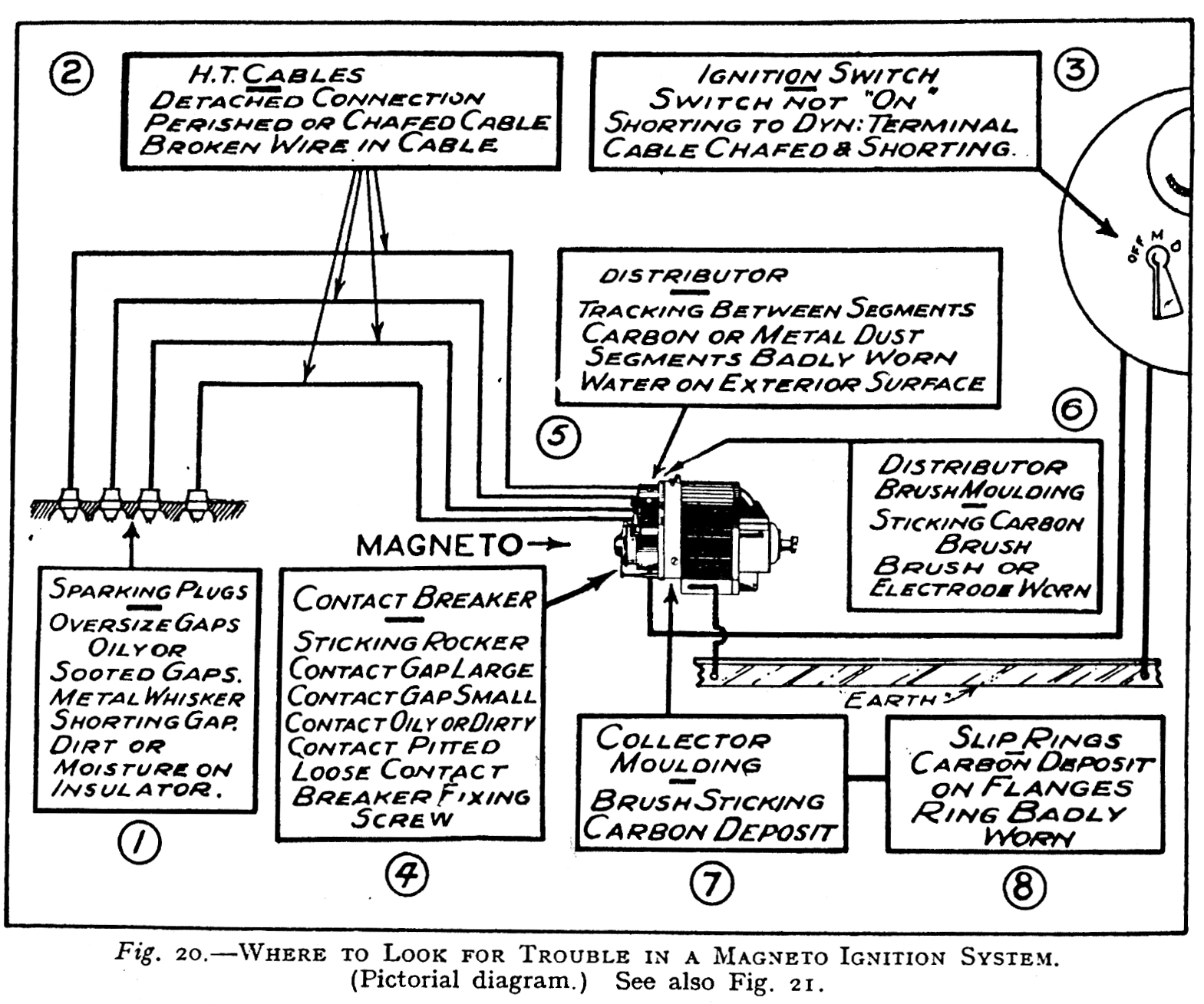

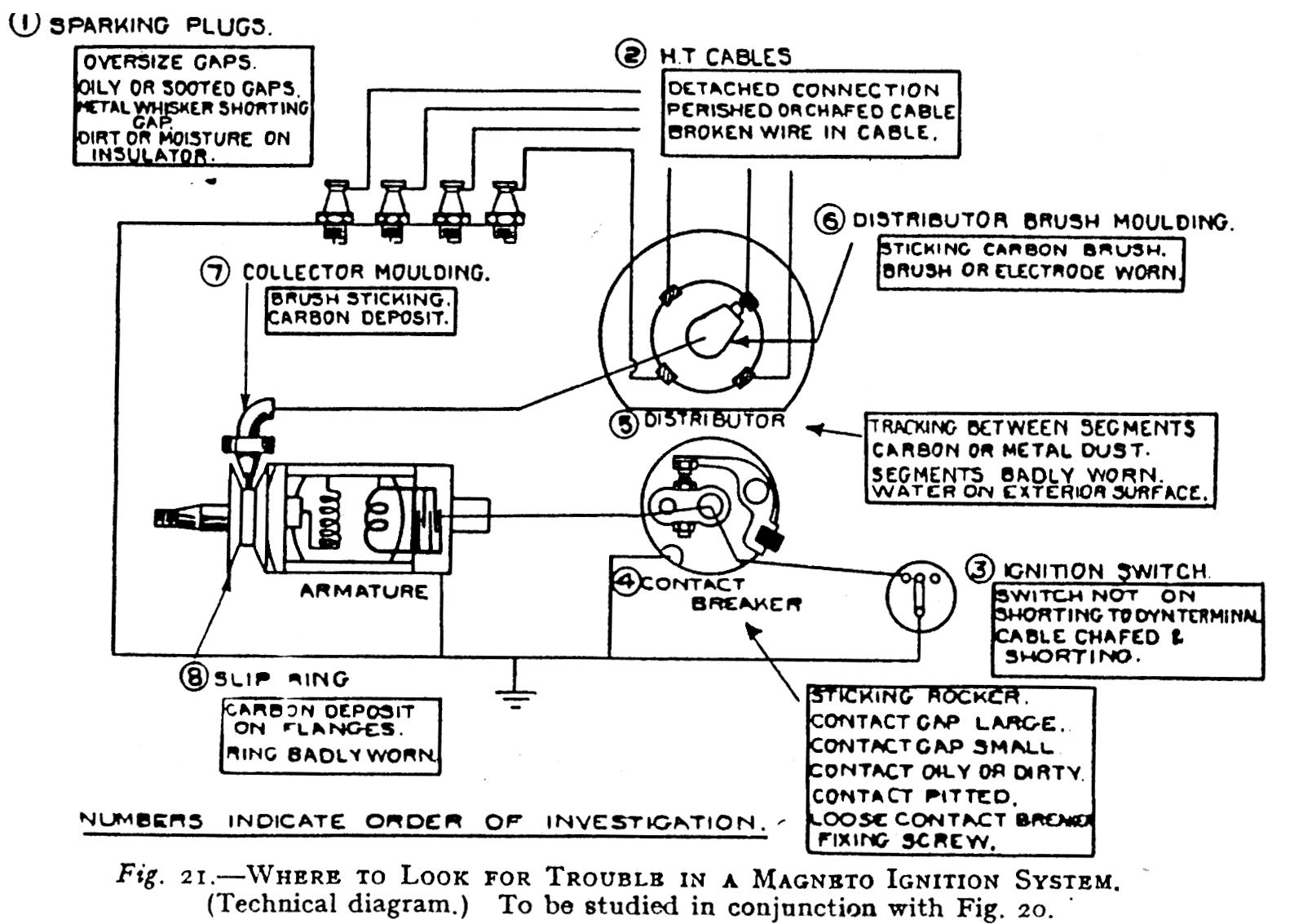

Testing and Fault Locating on H.T. Magnetos.

The usual symptoms are, of course, misfiring of the engine. A diagnosis

of this complaint is not so easily located with a magneto as with coil ignition,

and it is rather difficult to give ruleofthumb methods. However, the following

should be examined as a preliminary. If the engine refuses to fire at all the

switch wire should be disconnected from the contact breaker as the trouble may

be due to this wire having become chafed through, resulting in the primary being

permanently earthed; therefore, no break would take place in the primary circuit

when the points were opened.

Plugs.

Run the engine for a few minutes to warm it up, then switch off and

feel the terminal top of each sparking plug; if you find that one plug is

considerably cooler than the rest, this indicates that the plug has not been

firing regularly, and it should be removed for inspection, and, if possible,

another plug fitted for test. Very often a plug will appear to be in order

except for the fact that it is slightly sooted; do not confuse sooted plugs with

carboned plugs. If a plug is badly carboned, you naturally rightly suspect that

it is defective, but if a plug is only sooted, as though the mixture was too

rich, you are apt to pass it over. This soot, however, is highly conductive, and

the spark will track up the sooted porcelain or mica to the barrel of the plug

and result in misfiring.

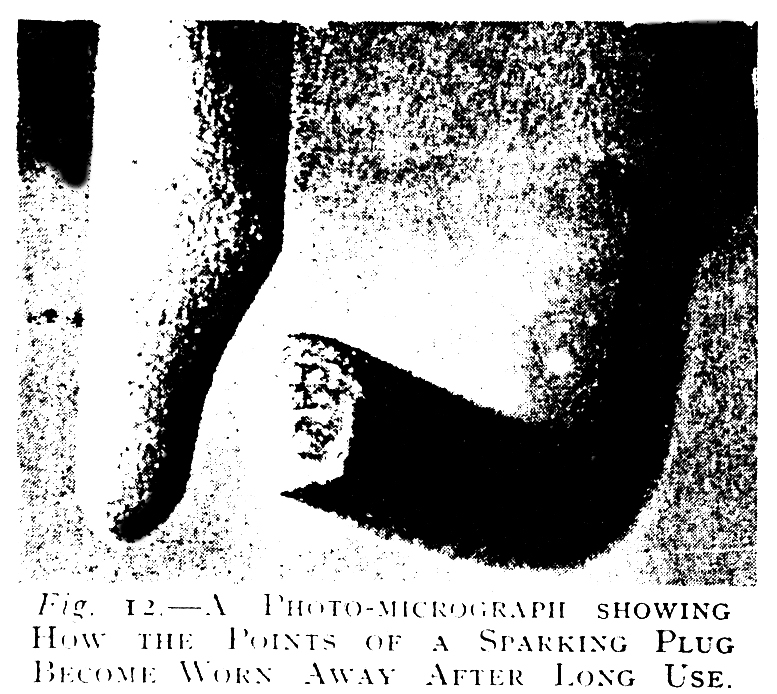

Too Great a Gap.

Another defect to look for in plugs is too great a gap due to the

electrodes having burnt back. This state of affairs will reflect seriously on

the secondary winding of the armature or coil, as the case may be, and is often

the cause of a breakdown in the armature or coil, owing to the increased

resistance to the H.T. spark.

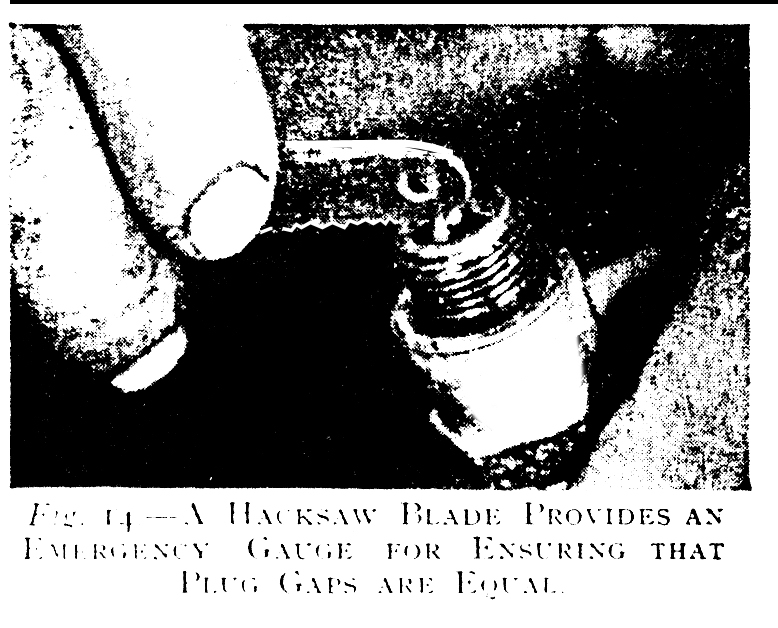

Having made a preliminary test of the plugs as just described, and found them to

be all more or less of the same temperature, a further test can be made by use

of a good class neon plug tester. Having satisfied ourselves that the trouble is

not due to plugs, let us proceed to the next point where trouble is likely to be

found.

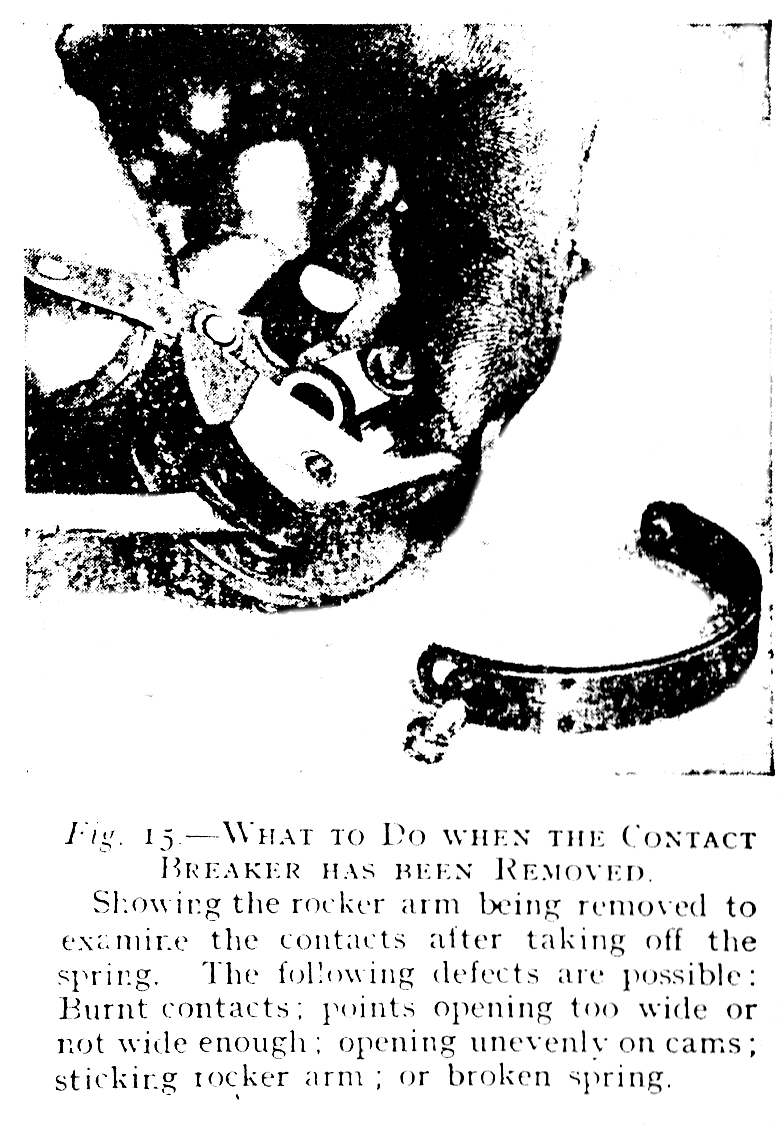

Contact Breaker Faults.

Remove the contact breaker cover and examine the contact breaker points

for the following defects: Burnt contacts; points opening too wide or not wide

enough (the correct setting being about 12 thou.); opening unevenly on cams;

sticking rocker arm; or broken spring. Any of the above defects, with the

exception of point adjustment, will necessitate the removal of the contact

breaker.

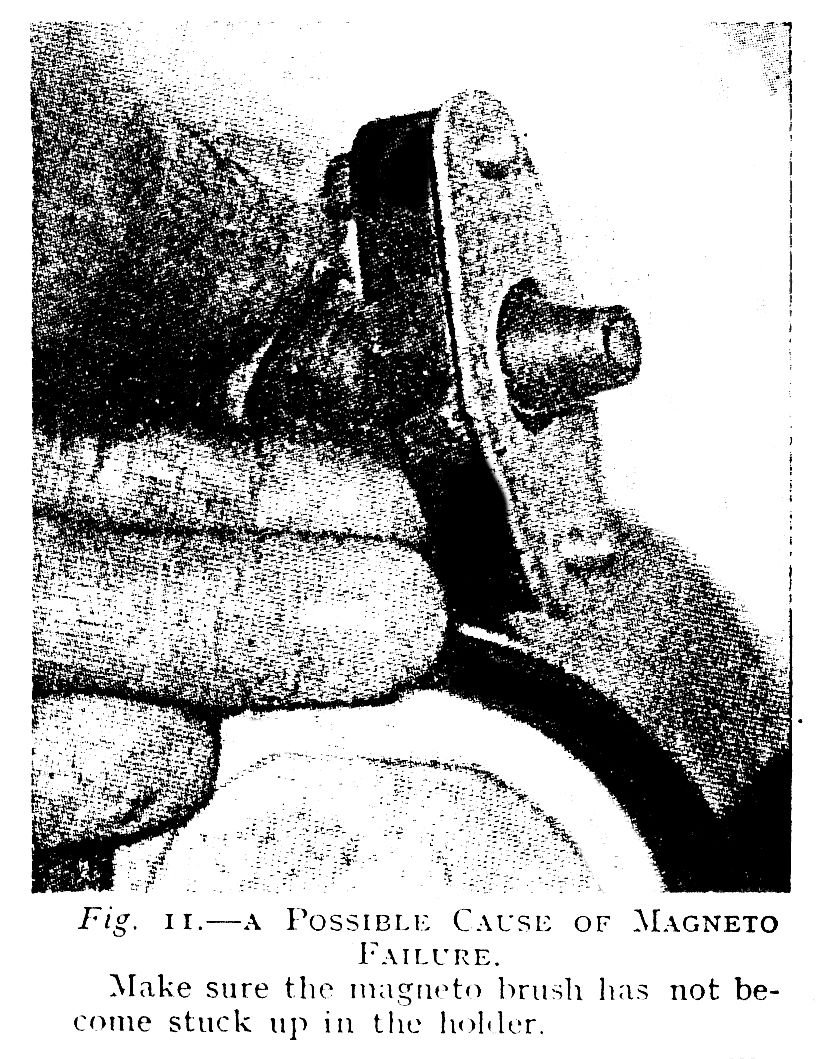

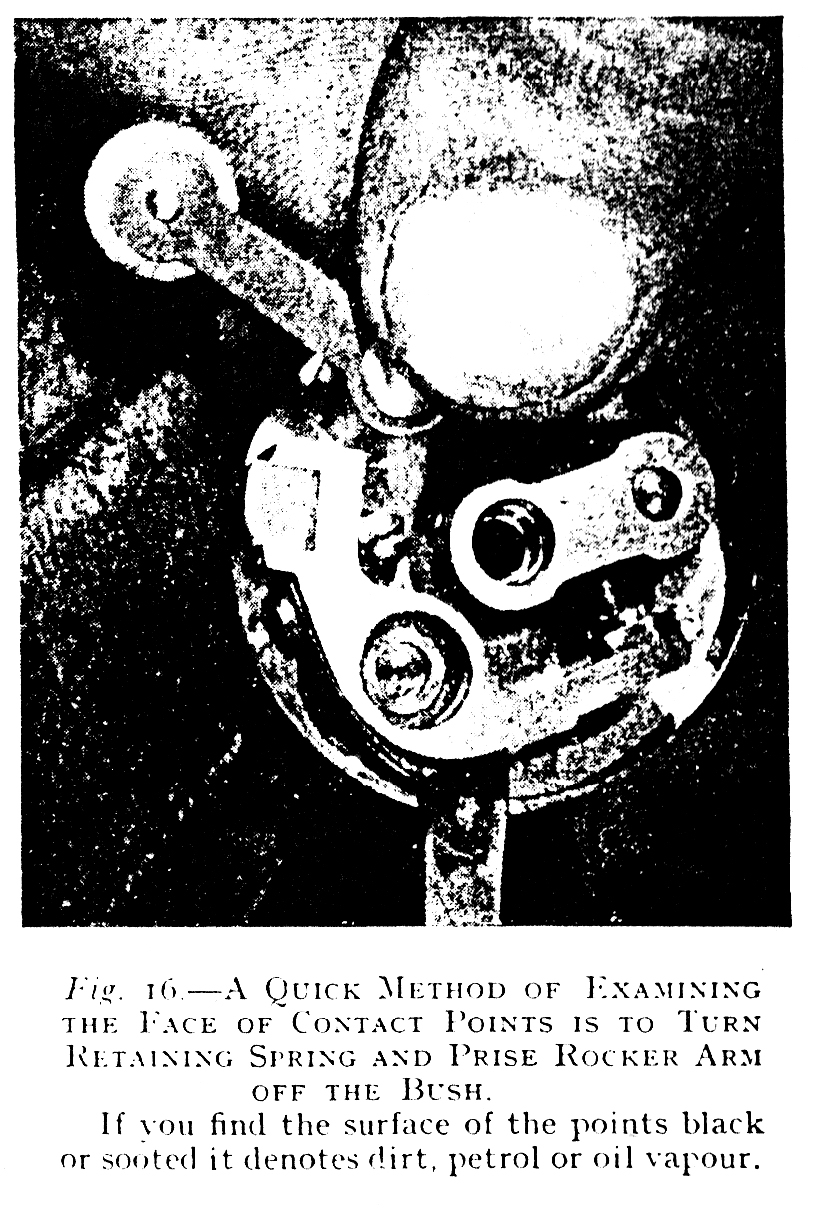

When removing this component, take care to see that the earthing brush is in

position and not stuck up. Another rather elusive contact breaker fault is due

to a badly worn fibre heel; this is the fibre block attached to the rocker arm

where it is actuated by the cams. As this heel wears down the points have to be

adjusted; on some types of contact breakers, it is possible for the adjustment

to be carried so far that it allows the rocker arm to foul the centre block in

which the stationary point is fixed. When this happens, continual misfiring

will take place and the only remedy is to fit a new fibre heel or complete

rocker arm, the latter recommendation being the most efficient, owing to the

fact that by the time this state of affairs has been reached the fulcrum pin of

the rocker arm will also have become worn. A rocker arm having a badly worn

fulcrum pin will wobble about badly when running, causing misfiring to take

place.

Assuming that we have found the contact breaker in order, let us now examine the

H.T. circuit.

Testing for Faults in the H.T. Circuit.

Testing the H.T. circuit of a magneto while it is in position on the

car is rather an unsatisfactory proposition, but nevertheless it has to be done

when it is not convenient to remove the magneto for a bench test.

The procedure recommended is as follows: remove a wire from one plug and lay it

on the cylinder so that the spark may jump to earth; start the engine, then hold

the disconnected plug lead about a 1 in. from the cylinder. If the H.T. circuit

is in order, the spark should jump this gap easily. If it does not, then the

magneto is definitely defective. Do not be misled by the fact that you can

obtain what you assume to be a good spark if you hold the plug wire say 1/8 in.

from the cylinder, as this spark will not be strong enough to jump the plug

points under compression. You must obtain a spark of at least ¼ in. for the plug

to fire satisfactorily under compression. On no account should the engine be

allowed to run with the disconnected plug lead in such a position that a spark

cannot jump to earth.

From the foreg oing

remarks it will also be clear that the. operation of removing all the plugs and

laying them on the top of the cylinders with the plug leads connected, then

cranking the engine and observing whether they are sparking or not, will be no

criterion as to the condition of the magneto.

oing

remarks it will also be clear that the. operation of removing all the plugs and

laying them on the top of the cylinders with the plug leads connected, then

cranking the engine and observing whether they are sparking or not, will be no

criterion as to the condition of the magneto.

FAULTS

WITH DISTRIBUTOR BOARDS, ROTORS AND PICKUPS.

FAULTS

WITH DISTRIBUTOR BOARDS, ROTORS AND PICKUPS.

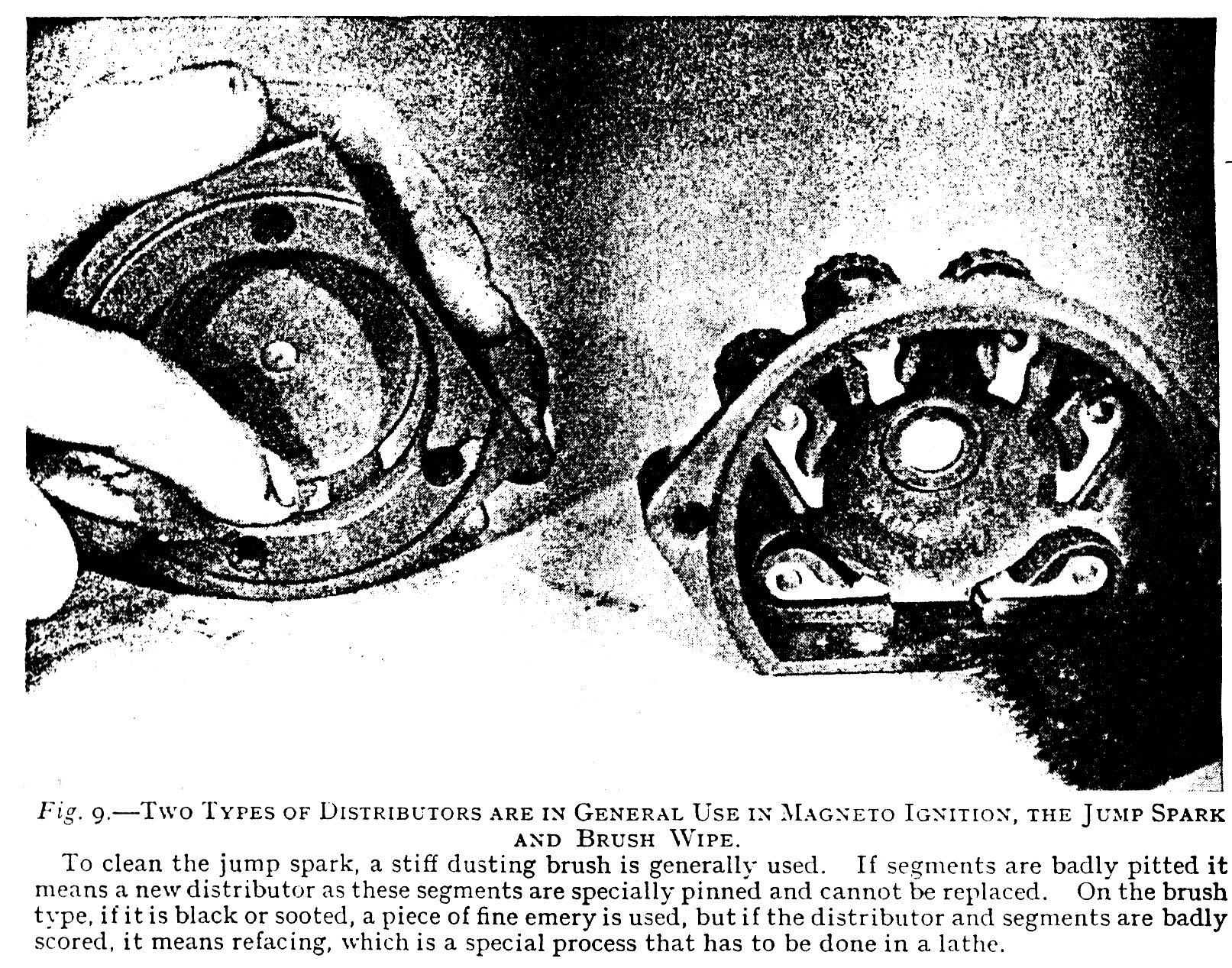

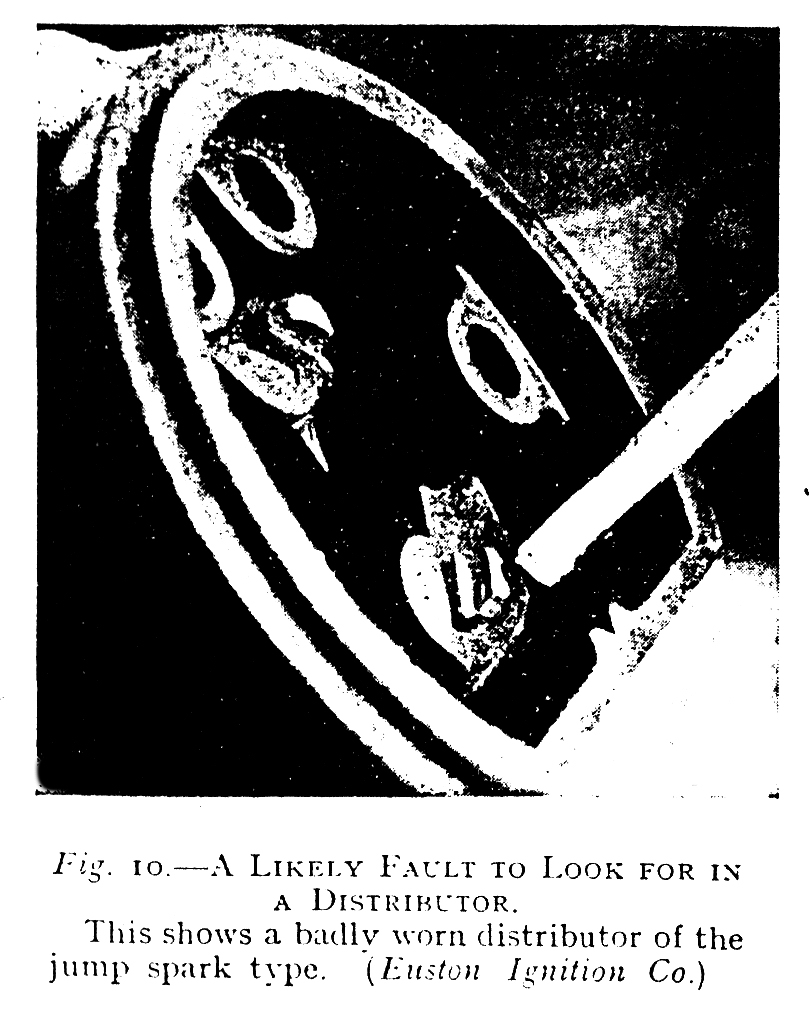

Should you find on testing the high tension that the spark is weak and

will only jump a small gap, the following components should be examined for a

possible visible fault.

Distributor Board.

Look for tracking between segments, tracking between cable terminals or

puncture at base or adjacent to fixing clips (see Fig. 22). The foregoing faults

are usually visible but in cases of doubt they can be tested on the H.T. test

previously described.

Rotors.

This component can usually be withdrawn after removal of the

distributor board; care must be taken not to let the carbon brushes fall out or

fall into the magneto. The most common failure with this component is a puncture

in the insulation, allowing the spark to jump to earth. A breakdown of this

description is very rare and is more often brought about by the mishandling of

the rotor, resulting in it becoming cracked.

The Pickup.

This component is situated at the slip ring end of the armature and

picks up the H.T. current from the slip ring.

Defects to look for in the pickup are puncture in insulation, tracking, carbon

brushes stuck up, broken or missing altogether. Let us assume that the

foregoing components have tested O.K. but still we obtain no results from the

magneto. The only obvious course is to remove the magneto for further bench

tests, which is dealt with in a later section.