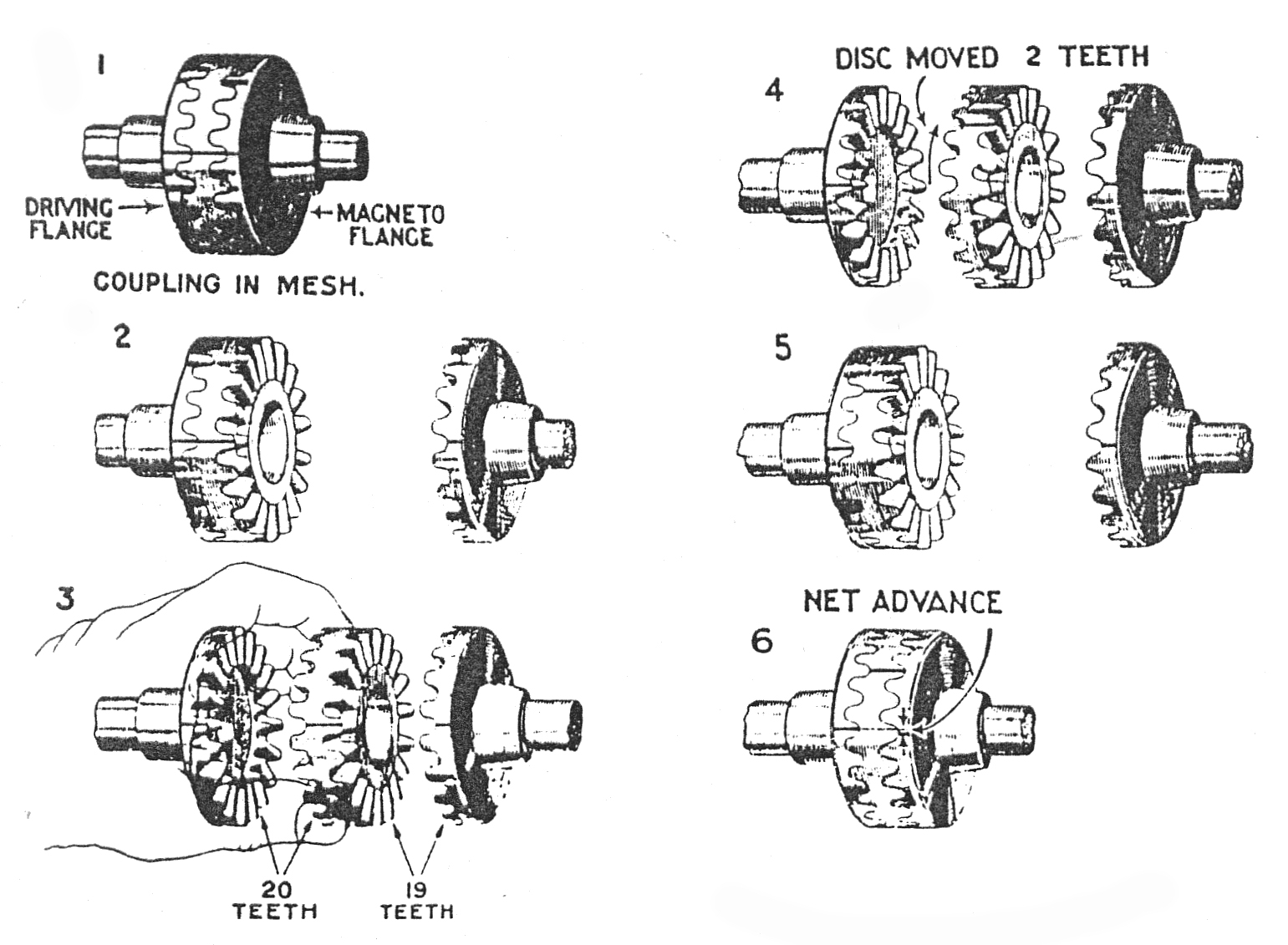

THE MAGNETO COUPLING

From the Austin Magazine

Many a car is not giving its true performance owing to the true ignition timing not being at its best position.

DESCRIPTION OF THE COUPLING.

We frequently find that the principle of the vernier coupling driving

the magneto is not thoroughly understood and we have endeavoured in this article

to explain it in such a manner that our Agents' mechanics can readily attend to

customer's cars so that they can obtain the best from them.

When the magneto has been timed by No.1 cylinder in the usual way, if on

checking the contact breaker position, or if after the engine has been running,

the ignition timing seems either too advanced or too retarded, the fine

adjustment provided by the vernier coupling can be used to set the timing as

required.

The coupling has 20 teeth on the driving flange side and

19 on the magneto side, and the minimum amount of adjustment is the difference

between the pitches of the two sets of teeth, namely 1/380th of a revolution. In

terms of one revolution, the pitch of the magneto side of the coupling is 1/19th

and that of the driving side 1/20th. Thus the difference is 1/19th less 1/20th.

(1/19 = 20/380. 1/20 = 19/380. 20/380 - 19/380 = 1/380)

To advance the ignition, the flange on the magneto spindle must be moved relative to the driving flange with the direction of the magneto rotation; and to retard the ignition, the magneto flange must be moved against the direction of the magneto rotation.

HOW TO USE THE COUPLING

Suppose the ignition requires advancing. Before starting, draw a pencil

mark across the two flanges and the rubber disc in case the original timing

position is lost. Slacken off the magneto strap, and leaving the rubber disc

engaged with the teeth of the driving flange, slide the magneto along its cradle

until the teeth of the flange on the magneto spindle are well clear of the

rubber disc, taking great care not to revolve the magneto spindle. The rubber

disc is now withdrawn from mesh with the driving flange and turned one or more

teeth against the direction of rotation of the magneto, being then put back into

mesh with the driving flange. The magneto spindle not having been revolved, it

will be found that the teeth on the magneto flange are not quite opposite their

matching teeth on the disc. Now slide the magneto back into its place so that

its flange teeth mesh with those on the disc. In so doing the magneto spindle

will be caused to revolve very slightly in relation to the driving flange in the

appropriate direction. The adjustment being so fine a movement of the disc of

two or three teeth in relation to the driving flange will usually be found the

smallest adjustment which makes any appreciable difference to the running of the

engine as regards engine timing. If further advance in the timing is considered

necessary the rubber disc should again be turned more teeth.

To retard the ignition timing the operation is as for advancing except that the rubber disc is turned with the direction of the rotation of the magneto.

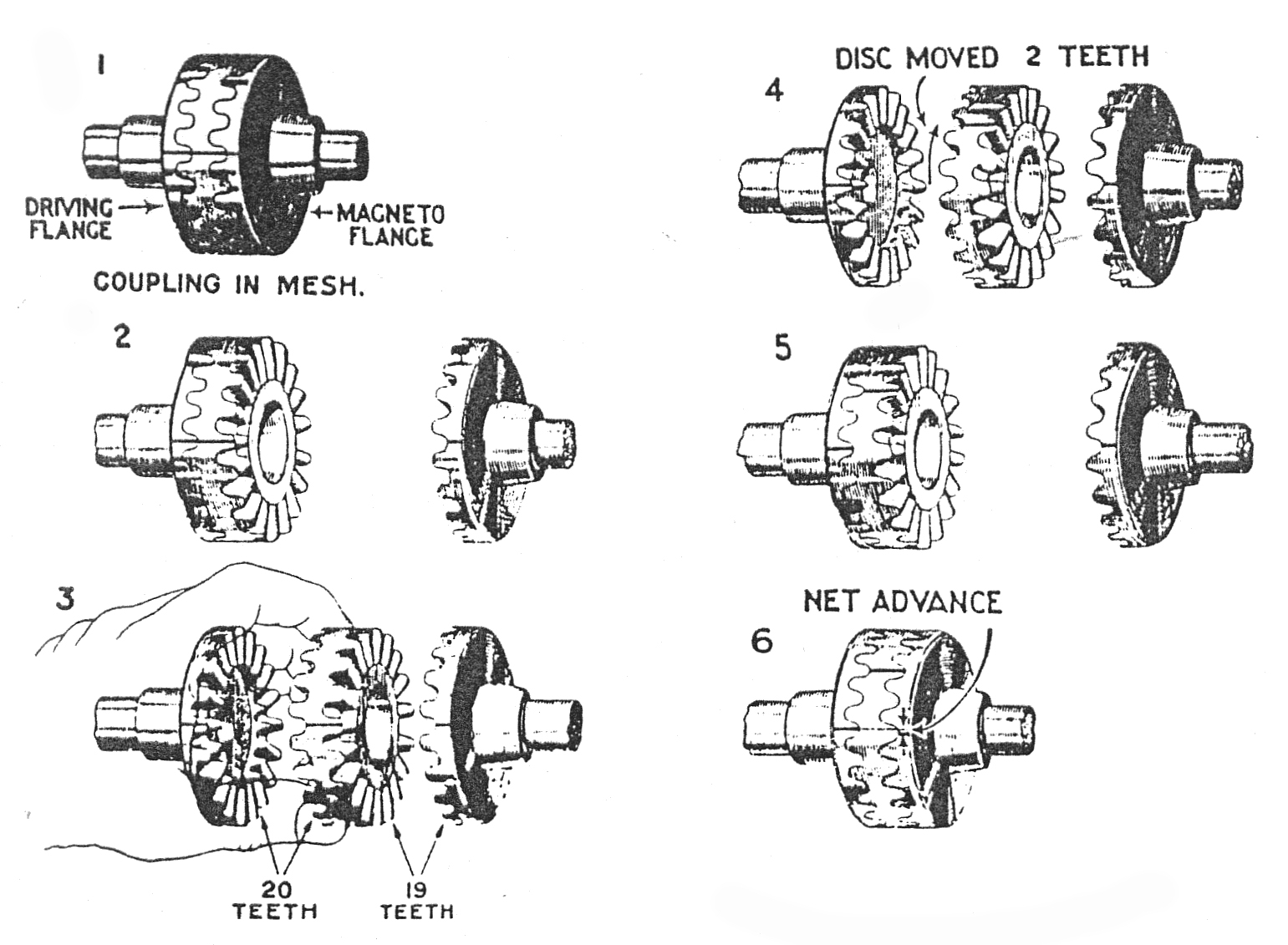

Key to the illustration.

The operations necessary to advancing the ignition setting:

1. The coupling in mesh.

2. The magneto drawn back so that the

magneto flange is clear of the rubber disc.

3. The rubber disc withdrawn from mesh

with the driving flange.

4. The rubber disc turned two teeth

against the direction of rotation.

5. The rubber disc put back into mesh

with the driving flange.

6. The magneto slid back into place to

make up the coupling.

For convenience of illustration the magneto flange is shown withdrawn further than is actually necessary.