LUBRICATING THE CLUTCH THRUST BEARING

From an original article in the MA7C's newsletter

The clutch thrust bearing is one of the hardest working

mechanical components in the Austin Seven drive train. This is particularly true

in the early three speed gearboxes where the thrust is continually turning.

Unfortunately, due to its hidden location there is a tendency for the

maintenance of the clutch thrust to be neglected. Lubricating the clutch

correctly and frequently is one of the most important requirements to ensure

long and trouble-free life.

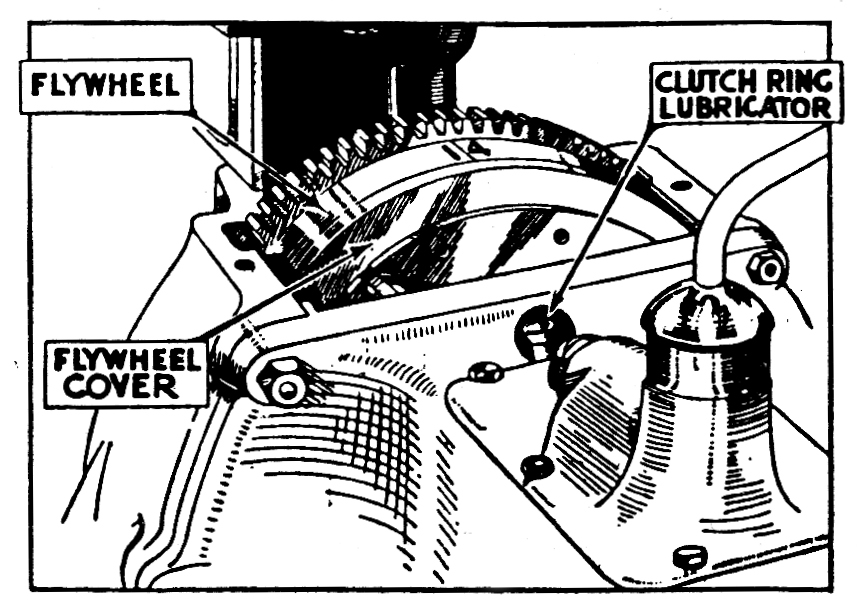

Regular lubrication is easier said than done. Because of its location the clutch thrust is difficult enough to reach for nimble athletic types, let alone the more mature and rounded of us. Those newcomers to the Austin Seven will note that the clutch thrust is lubricated via an inspection hole in the gearbox bell housing. The earlier three speed boxes have a small metal cover over this inspection access.

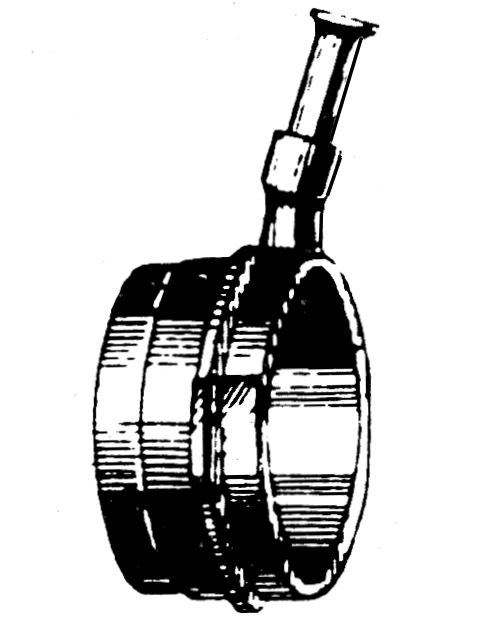

The lubricating oil reaches the bearing down a short

length of pipe which can just be seen inside the inspection hole. The top of the pipe is slightly funnelled to aid the use of an oil can. There

will be no problem applying oil if the pipe is easily accessible, the problems

start if it is broken off or the pipe has moved out of sight. which can be

caused by clutch wear or the toggle leavers wearing into the cover plate.

The top of the pipe is slightly funnelled to aid the use of an oil can. There

will be no problem applying oil if the pipe is easily accessible, the problems

start if it is broken off or the pipe has moved out of sight. which can be

caused by clutch wear or the toggle leavers wearing into the cover plate.

To make lubrication easier in the above circumstances I

have developed the following method: obtain a short length of flexible cable, a

section of inner wire from an old choke or starter cable is ideal. Enter this

wire into the lubrication pipe or in the case of a broken pipe straight into the

thrust bearing body. With the wire in position proceed to lubricate the bearing

by simply running drops of oil down the wire.

Cars in daily use need oiling on a weekly basis, whilst those not so frequently

used can be done on a monthly basis.

Eddie Loader with many thanks.