KING PIN RENEWAL

FOR some reason the average owner-driver often overlooks the king-pins and bushes when diagnosing steering wander and wheel wobble. Assiduous attention is given to adjustments in the steering box and to the amount of toe-in of the road wheels, all of which adjustments can be made with comparative ease, while the main cause of the defect-wear in the stub-axle bushes and the king-pins-is often overlooked.

It is

a curious fact that the adjustments and repairs which arc easy to carry out

always receive careful attention, while the awkward jobs arc invariably

neglected. For instance, how readily the mechanic jumps to the conclusion that

steering backlash is caused by up-and-down play in the steering column, simply

because it is usually a very simple job to take up the play at this point,

whereas the possibility of worn bushes in the steering box, the renewal of which

would necessitate the removal and complete dismantling of the box, is the last

thing to be suspected.

Testing for Wear

In the case of worn swivel-pin joints, however, there is some excuse for a non-technical man not diagnosing the trouble right away. One of the classic tests is that of shaking the road wheels from side to side. This is suggested as a test for slackness in the wheel bearings. Naturally, lateral movement at the edge of the wheel may equally well be caused by slack pivot pins, while in practice it is usually due to a combination of the two. The fact that the king-pins cannot be seen easily by Me person carrying out the test also helps in the delusion that the play is all due to the wheel bearings.

Play in the king-pins can, however, be detected by jacking up the front axle and watching for movement of the joint while a second person moves the wheel backward and forward and also lifts it up and down. This test will reveal up-and-down movement of the stub axle, usually traceable to worn bush flanges. The wear indicated by the fiat test is, of course, the more serious. Up-and-down movement does not matter so much in itself, but the resulting gap allows the ready ingress of dirt and water, with the inevitable speeding up of the wear of the bushes, resulting eventually in side play as well.

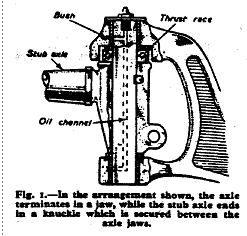

Steering Head Arrangements

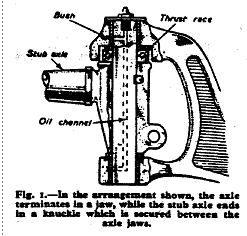

Before giving details of the actual work of renewing the Worn pins and bushes, a few notes on the various arrangements of steering heads will not be out of place. One common arrangement is that shown in Fig. 1. The sale ends in a knuckle through which the king pin passes. The pin is kept in place by means at a tapered cotter. The projecting ends of the king-pin rotate in bushes held in the jaw end of the stub axle. In some designs there is also a thrust tact between the knuckle of the axle and the lower jaw of the stub axle, but with most .light cars this is omitted.

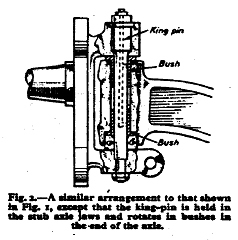

In

Fig. 2 the arrangement is reversed, the front axle terminating in a law fitted

with bushes, while the king pin is secured in the stub axle. In this particular

example a ball thrust race is used to take the load of the axle.

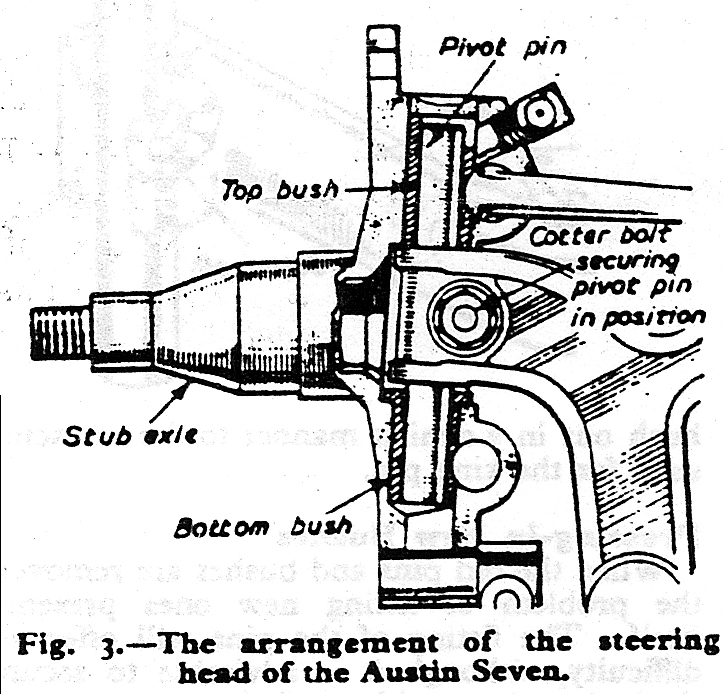

A third arrangement is depicted in Fig. 3. This is similar to Fig. 1 except that the pin is held in the stub-axle jaws and rotates in bushes in the end of the axle. The advantage of this design is that when wear takes place the pin can, if necessary, be turned down and new bushes supplied to fit. With the other arrangements this cannot be done since it would be impossible to reassemble the parts; and new pins must therefore be used.

Removing Old Pins and Bushes

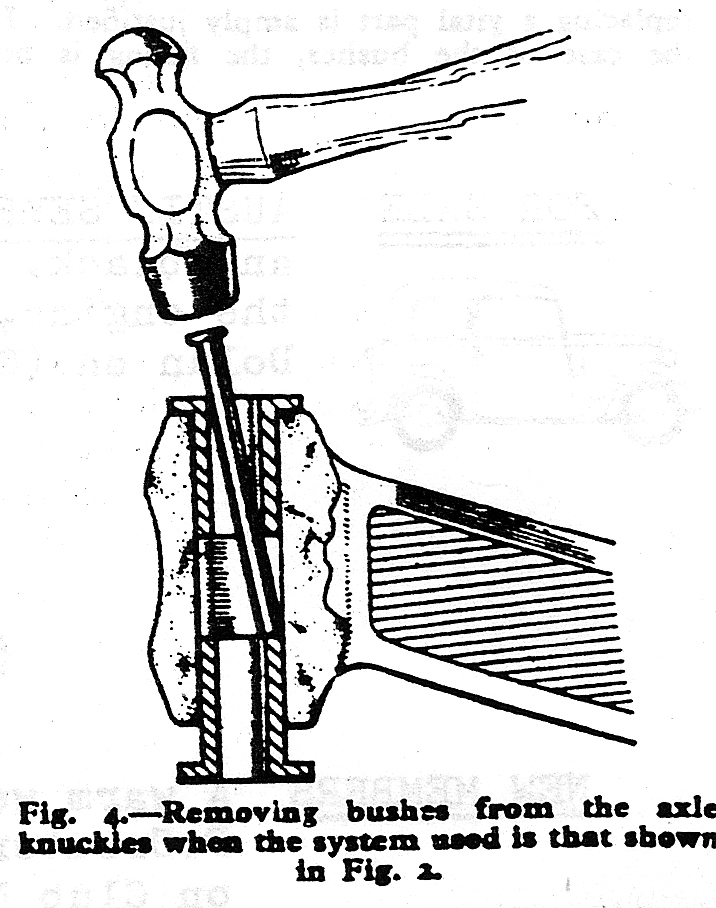

There

is a disadvantage with the arrangement shown in Fig. 3 in that it is sometimes

rather difficult to remove the bushes. However, a drift used after the manner

shown in Fig. 4 will usually do the trick. It is a very good idea to brush over

all the pans with penetrating oil before starting the work of dismantling. This

will help to free rusted-up cotters, nuts, etc.. It is also wise to remove the

axle entirely from the car.

The parts can then be dismantled and fitted on the

bench. Of course, there is no objection to leaving the axle in place if

preferred, but with most light cars the small extra labour involved in removing

the spring staples is well repaid in convenience of operation. Whether the axle

is removed or not it will be necessary to take oil* the wheels, hubs and brake

gear, leaving the stub axles stripped before attempting to remove the king pins

and bushes.

The parts can then be dismantled and fitted on the

bench. Of course, there is no objection to leaving the axle in place if

preferred, but with most light cars the small extra labour involved in removing

the spring staples is well repaid in convenience of operation. Whether the axle

is removed or not it will be necessary to take oil* the wheels, hubs and brake

gear, leaving the stub axles stripped before attempting to remove the king pins

and bushes.

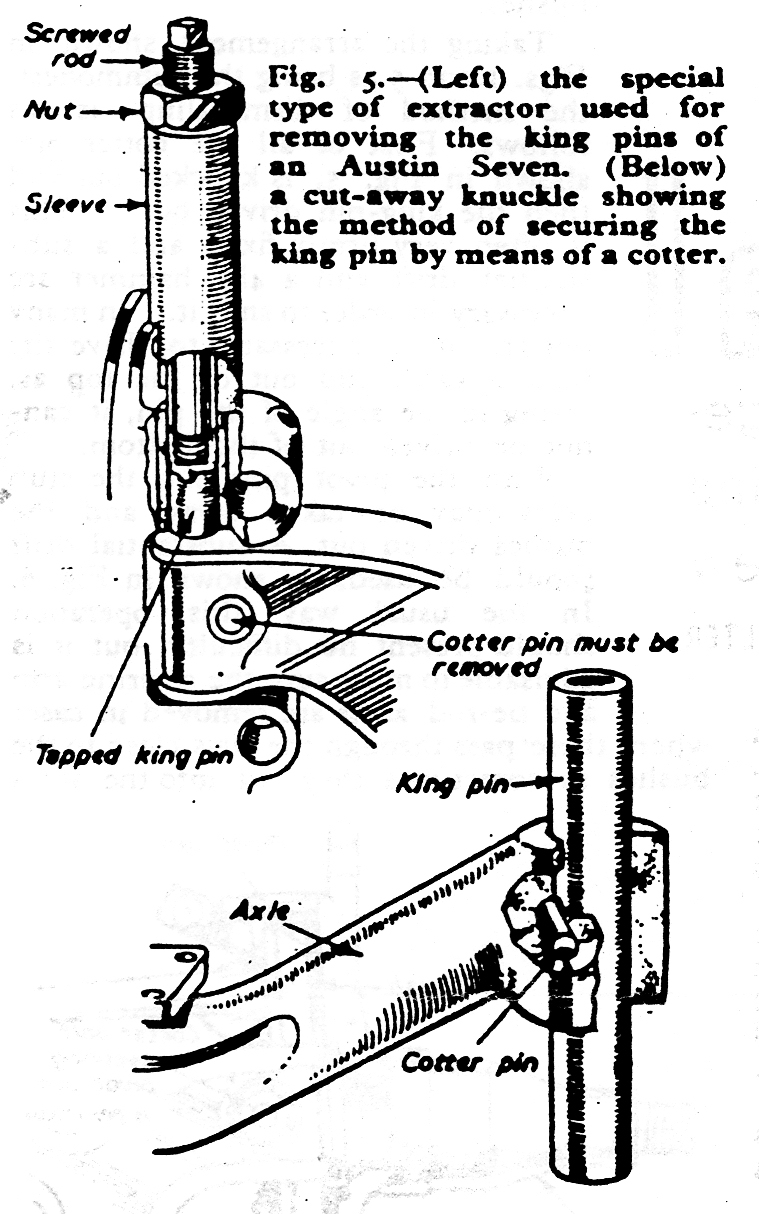

Taking the arrangement shown in Figs. 1 and 5 as being the commonest, the method of dismantling is as follows. First of all the cotter pin, shown in Fig. 5, is knocked out and then the king-pin driven out. This is often very firmly fixed and a substantial drift and a 41b. hammer arc necessary in order to shift it. In many designs it is necessary to drive the pins upwards and out of the top as, owing to the angle of the pin, it cannot be driven out of the bottom.

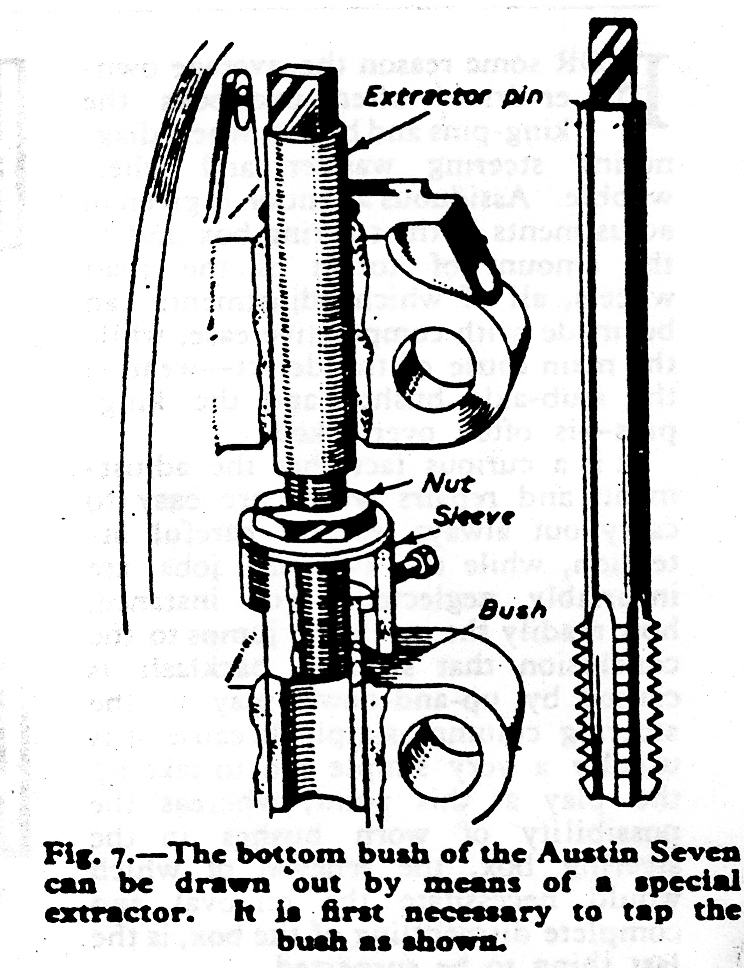

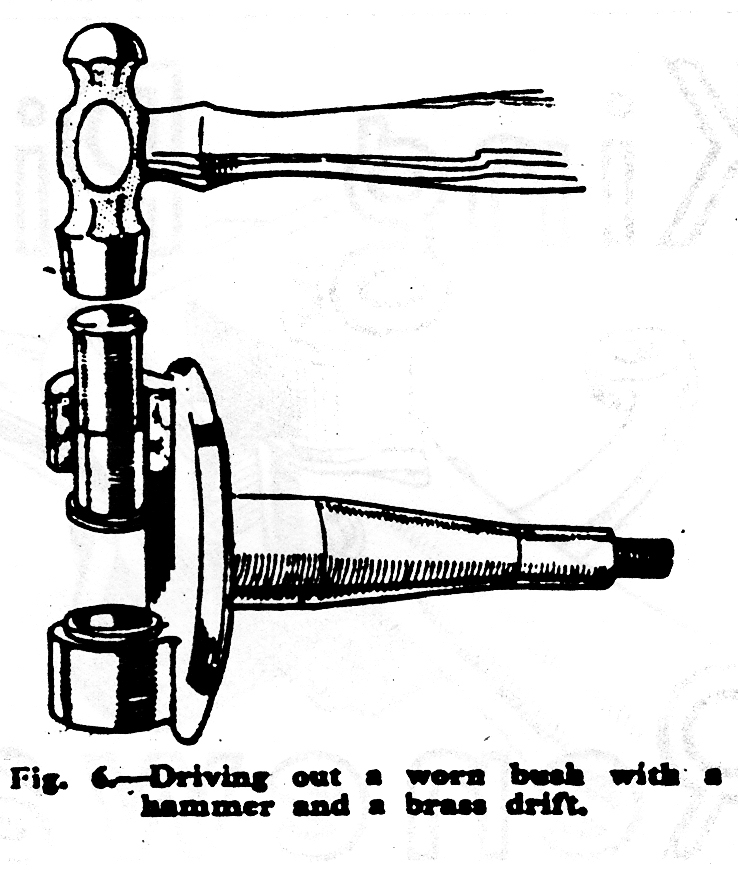

With the pivot pins out, the stub axles may be taken away and the bushes driven out. A substantial drift should be used, as shown in Fig. 6. In the usual way this operation should present no difficulty, but it is advisable to make sure the steering arm and tie-rod arms are removed in cases where these pass through the jaws close to the bushes as sometimes they cut into the sides of the bushes and act as cotter pins, thus keeping the bushes from moving The Austin Seven needs special mention as presenting certain difficulties of its own. The bottom bush, for instance, fits in a blind hole and, therefore, neither the king pin nor the bush can be driven out in the normal way. An extractor for the king pin similar to that shown in Fig. 7 can be obtained from garages. It consists of a centre screwed rod, which screws into a tapped hole in the top of the swivel pin. A sleeve slips over the rod and a nut is then screwed on the rod and run down till it bears on the top of the sleeve. Tightening of the nut draws the rod upward, and with it the swivel pin.

In

order to remove the bottom bush it is necessary to tap a thread in it and then

to use a screwed extractor which draws the bush out in a

similar mariner to the

extractor used for the king pin.

similar mariner to the

extractor used for the king pin.

Pressing-In New Bushes

When the old pins and bushes are removed the problem of fitting new ones presents itself. The fitting of the pins will offer no difficulty, although it is advisable to secure them in place with entirely new cotters. The old ones are usually slightly damaged in removal and the small extra expense in replacing a vital part is amply justified. In the case of the bushes, the fitting is not usually quite so straightforward. They should be, and usually are, a press-fit in the stub axle jaws, and when driven in they usually contract slightly and bind on the pin. It is difficult to foretell' just how tight they will become when fitted, since if tested on the pin before they arc inserted they will probably be a good sliding fit. The job which now has to be undertaken is the scraping of the bushes. The skilled mechanic this will present no difficulty, although it is a somewhat tedious task. The difficulty for the person with no workshop practice is that of paring off just sufficient of the bronze to make an easy but not a "sloppy" fit for the pin.

If he does not feel confident to undertake this delicate work the unskilled worker is still left with two alternatives - either to take the pins and stub axles to a local engineer and get him to fit them, or else to buy an expanding reamer specially designed for the job. A reamer will undoubtedly make a sound job, but unfortunately its use is strictly limited and it is therefore hardly worth while for the average owner-mechanic to buy one.

King Pins Should Not Be Filed

It may at first glance appear easier to take a shaving of metal off the swivel pin instead of attempting to ream or scrape out the bushes, but except in the case of the arrangement shown in Fig. 3-(which is not a common one) this is not possible. If the whole pin is turned down it will become a loose fit in the axle, or if only that part which revolves in the bushes is reduced in diameter, then it will be impossible to assemble the job, since the larger diameter of the centre part of the pin will prevent it passing through the top bush.

The best way to insert the bushes is to press them into position. Ether they may be pressed in by means of a vice, or else drawn in with the aid of a screwed rod and the necessary washers and nuts. However, if great v care is taken not to damage the edges of the t: bushes and also care is -ken to keep them square, they may be driven in by means of a drift. The danger of driving them in is manifest if they arc too tight in the stub-axle jaws.

An important point to remember when fitting bushes is to get the oil holes in the bush in register with those 'in the forging. Often the bushes are supplied without holes, and it is then best to fit the bushes first and afterwards to remove the grease nipples on the stub axles and drill straight through into the bushes. In no circumstances must the job be assembled without provision for lubricating both top and bottom bushes.

From PRACTICAL

MOTORIST & MOTOR CYCLIST January 1955