During a recent chat about tapers and keyways, I advocated using

engineers blue to indicate the need to remove metal from the boss of the

flywheel to stop it from being tightened against the rear main bearing. The

removal of metal, if necessary, is also advocated in Doug Woodrow's "Austin 7

Manual". I am indebted to Glyn Llewellyn who pointed out some possible

weaknesses with this basic technique and concerns the operation of the oil

thrower.

For the oil thrower plate to do its job, it needs to be pinched

between the flywheel boss and the rear main inner journal. Two types of oil

thrower exist - the original pattern has a swaged ring around its inner diameter

and the other has three or four heavy dimples in the same area. The situation we

are trying to achieve is where the flywheel is hard on its taper with the oil

thrower pinched between the flywheel boss and the rear main. This can best be

gauged by tightening the flywheel, without the key in place, on the crankshaft

on the bench before engine assembly takes place.

However, if you don't have this luxury, i.e. you are not rebuilding

the engine, the oil thrower can be dimpled with a punch and the flywheel

tightened on its taper (having already been lapped on) without the key in place.

It should require the use of a puller to remove and the dimples on the thrower

should show signs of compression.

If this is the case, all is well. If, however, the flywheel

requires only a little effort to remove it, this indicates that the boss is hard

against the rear main. This should also be evident from flattening the oil

thrower. In this case, it will be necessary to remove some metal from the boss

to achieve the correct clearance which still pinches the oil thrower but does

not make it solid against the rear main bearing.

Finally, put the flywheel back with the key in place and make sure

it tightens to the same place. I must stress the need to check clearances on

woodruff keys - I noted three examples of damage on the Euro Tour due to poorly

fitted keys - original Austin spares are too valuable to make mistakes which

damage them or render them unusable!

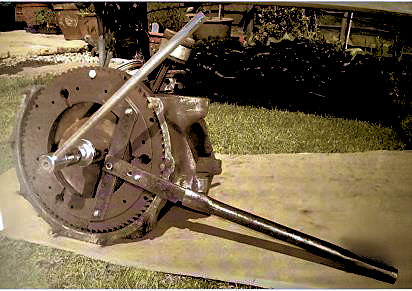

tool for holding

the flywheel when undoing or tightening the flywheel nut. It is much less risky

than putting a bar into one of the flywheel holes and resting the bar on the

crankcase. The conduit handle doubles up as a handle for other tools saving

space and weight in the car.

tool for holding

the flywheel when undoing or tightening the flywheel nut. It is much less risky

than putting a bar into one of the flywheel holes and resting the bar on the

crankcase. The conduit handle doubles up as a handle for other tools saving

space and weight in the car.