tch

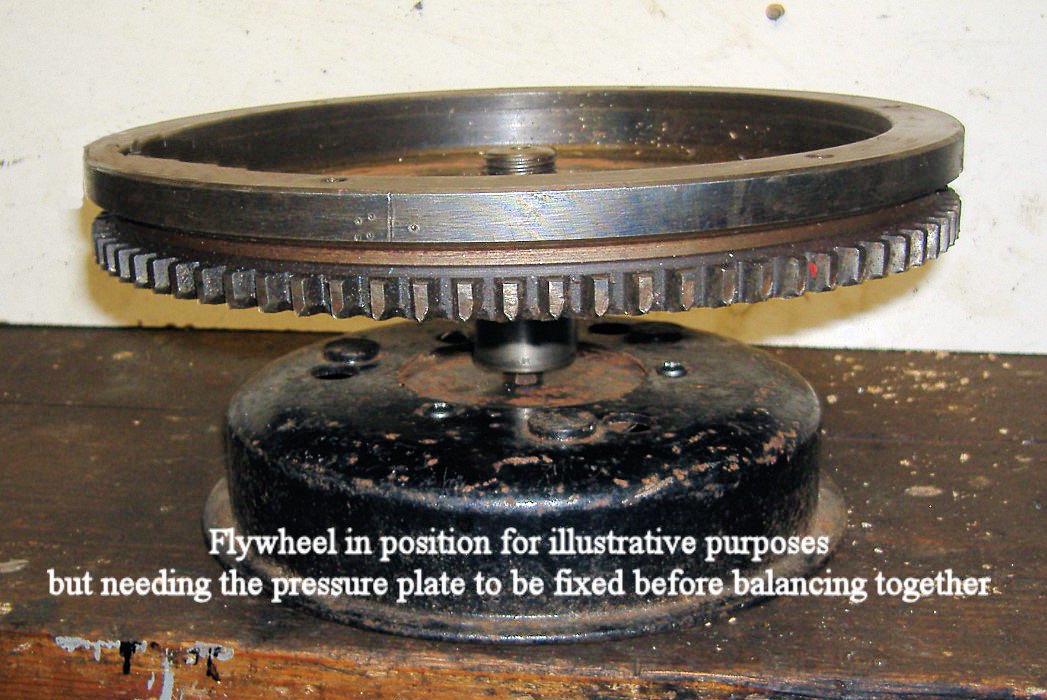

pressure plate is bolted to it, it is likely to become out of balance and worth

checking before attaching it to the engine crankshaft.

tch

pressure plate is bolted to it, it is likely to become out of balance and worth

checking before attaching it to the engine crankshaft. To achieve this, cut off the rear portion of a condemned crankshaft (it does not take long with a hand hacksaw with a sharp blade) then put it in the lathe and turn off the cut end and bore out the end, so that the pivot point is in the threaded portion of the crankshaft end. The pivot point will need to be created by a final drill of small diameter and a pivot spike will need to be fabricated on an old brake drum, for example.Finally, bolt the pressure plate and flywheel together and balance on top of the spike. To balance the pressure plate and flywheel together, add extra washers to the light side.

If you are rebuilding a clutch pressure plate and do not want to remove the flywheel from the engine, you could use a spare flywheel, first checking it is in balance before bolting the refurbished pressure plate to it and balancing the pair. If the spare flywheel was balanced and the pair are in balance, then the pressure plate must be in balance too.

Roger Ballard DA7C