method I have evolved to overcome the problem.

method I have evolved to overcome the problem.

PART 1

Have you ever got

frustrated with clutch springs and toggles flying everywhere when you’re trying

to offer up the clutch assembly to the flywheel after a relining job? If so, you

might be interested in a method I have evolved to overcome the problem.

method I have evolved to overcome the problem.

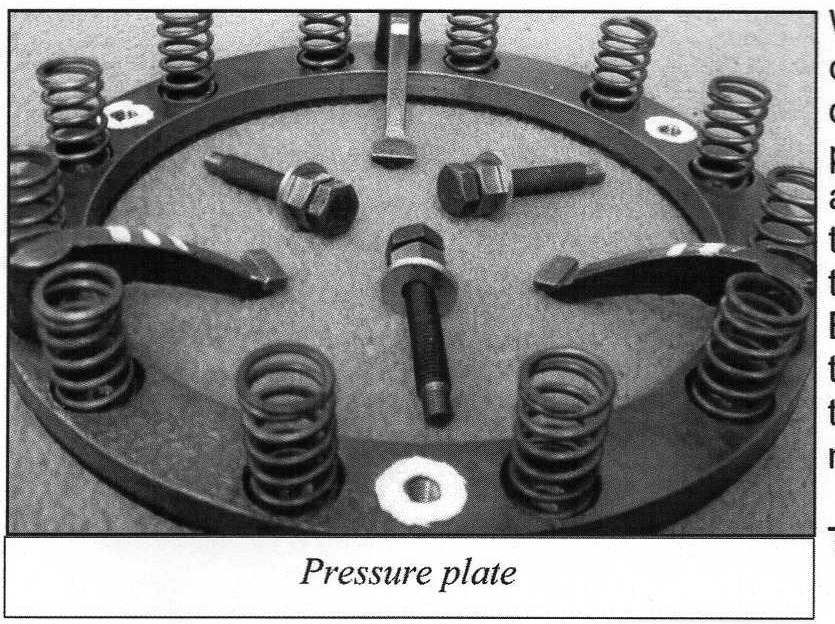

¡ Before fitting the new lining to the pressure plate, tap out two diametrically opposite holes in the spring recesses to ¼ BSF. (photo 1.)

¡ In the clutch cover, drill out the corresponding holes to ¼”. (photo 2.)

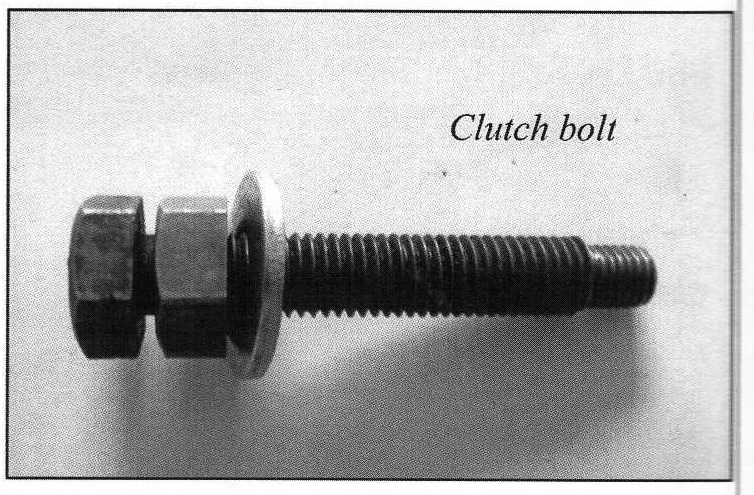

¡ Obtain two ¼ bsf set screws about 2.5” long and two nuts to use as clamps. (photo 3.)

¡ When

ready to assemble, place the relined pressure plate face down on the clean bench

and place the springs in their recesses. Carefully fit the clutch cover over the

toggles and mate it up with the springs. Having fitted the nuts to the top end

of the set screws, feed them through the enlarged holes in the clutch cover and

screw them gently into the treaded holes in the plate, taking care not to got

too far and damage the lining.

¡ Gradually tighten up the nuts alternately until the springs are completely compressed and you are left with one solid lump which you can now offer up to the flywheel without having to struggle to keep everything in place whilst fitting and tightening the fixing bolts. (photo 4.)

¡ Once the clutch is thus fitted you can remove the clamping bolts and put them in a labelled tin in the Austin Seven tools drawer in case you ever need them again.

To avoid removing the nicely fitted flywheel from its taper on the crankshaft I have relined the centre plate instead. This has worked very well on both my 1926 Chummy and my 1923 Austin 12/4.

JOHN DUNN (BA7C)

With many thanks—Ed.

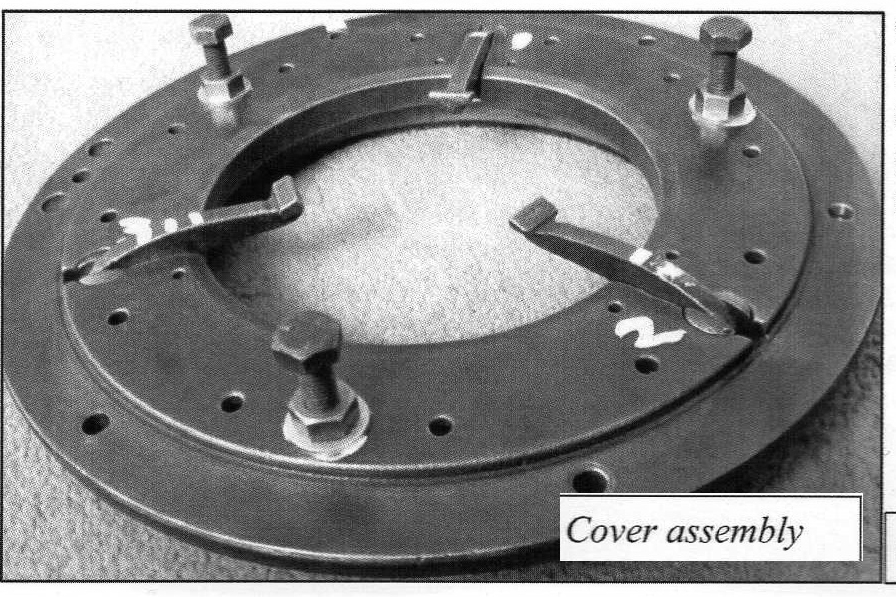

UPDATED ARTICLE - PART 2

This is a modification to the clutch to make

assembly and dismant ling

of the clutch cover/ pressure plate much easier and fitting the mousetrap

springs stress free. The objective is to hold the cover/pressure plate assembly

together whilst dismantling the clutch without straining the mousetrap springs

on a 4-speed clutch or springs flying apart on a 3 speed. You can carry out this

modification when relining the clutch or any time you have access to the clutch.

ling

of the clutch cover/ pressure plate much easier and fitting the mousetrap

springs stress free. The objective is to hold the cover/pressure plate assembly

together whilst dismantling the clutch without straining the mousetrap springs

on a 4-speed clutch or springs flying apart on a 3 speed. You can carry out this

modification when relining the clutch or any time you have access to the clutch.

When the clutch cover and pressure plate are

dismantled, drill three equidistant holes 5.5mm diameter in the clutch pressure

plate, then place the pressure plate onto the cover plate and mark these hole

centres on the inside of the cover plate. Drill three pilot holes through the

clutch cover. Tap the 5.5mm holes 1/4 BSF, drill out the pilot holes in the

cover plate to 9mm. These are clearance holes for the three spring compression

bolts we are about to make.

Take three 5/16 x 2" BSF set bolts, reduce the ends to

1/4" diameter for 3/8 of an inch and thread 1/4 BSF. This gives you a shoulder

to lock the bolts into the

pressure

plate. Fit a 5/16 BSF nut and plain washer to the bolt and run the nut up to the

bolt head — the washer needs to be fairly thick so that it does not distort.

pressure

plate. Fit a 5/16 BSF nut and plain washer to the bolt and run the nut up to the

bolt head — the washer needs to be fairly thick so that it does not distort.

To assemble pressure plate and cover, place pressure

plate flat on the bench, fit clutch springs in the plate, stand clutch levers

vertical and drop cover over levers onto springs. Check all springs are properly

located. Fit your three compression bolts through the cover and screw into

pressure plate tight. Screw down the three nuts evenly to compress the springs-

tighten down until fully compressed. This drops the levers and makes it easier

to fit the mousetrap springs. The whole assembly can now be fitted to the

flywheel. Once bolted up the compression nuts can be released gradually and the

clutch plate centred. Do not forget to remove the bolts.

Terry Griffin (BA7C)