IMPROVING THE STEERING ON

PRE-RUBY MK.II SEVENS

BY INCREASING THE CASTOR

ANGLE

WHAT IS CASTOR ANGLE?

Castor angle is the angle

the kingpins are off-set from vertical. Itís the small amount of Castor Offset

on the ground that allows for self-centring steering of cars and the

straight-line stability of bicycles. It is generally believed that the optimum

castor angle for Austin Sevens is 6.5o.

HOW CAN THE CASTOR

ANGLE BE MEASURED?

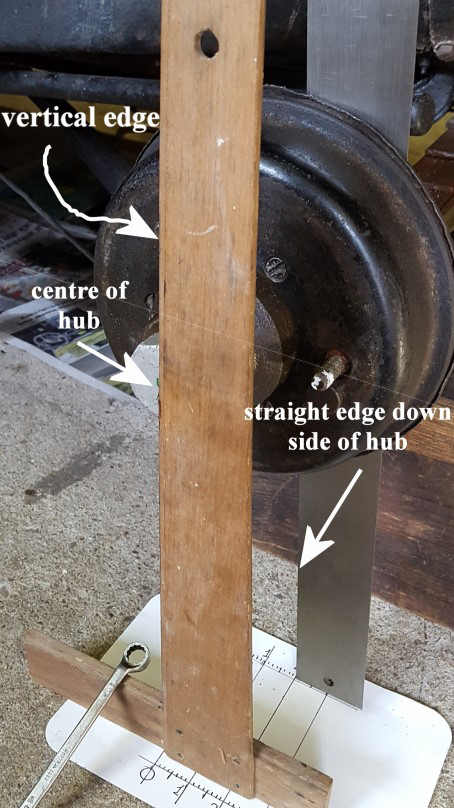

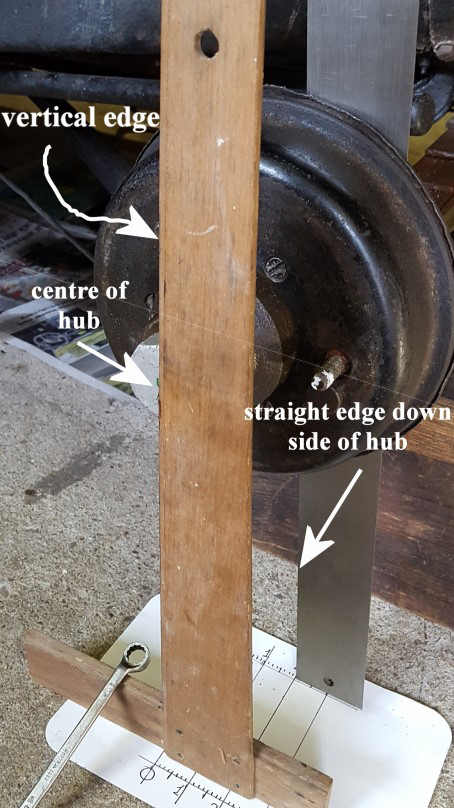

Usefully, the front of the inside of the

front hub, around the kingpin, has a flat face that is parallel to the kingpin

and this can used with a suitably long straight edge. It can be measured with a

large protractor and plumb-line or, as this article describes, by measuring the

offset on the ground.

HOW CAN THE CASTOR

ANGLE BE ALTERED?

The best, and most accurate and permanent

way, is to completely dismantle the front hub, remove the kingpins, insert a

tight-fitting rod into the axle, heat the axle to red hot and twist the end of

the axle to the correct alignment.

Another method entails lowering the central ball joint

at the pointed end of the radius arms so as to rotate the axle. However, this

entails some clever engineering. A much simpler method, described here, simply

twists the A-shaped radius arms which induces a change of angle of the front

axle without removing anything except the wheels.

However, this can only be done with early pre-Ruby

Mk.2 axles where the radius arms are fixed to the front axle with a large,

single, nut around which they can be twisted. Later axles have two fixing nuts

which obviously wonít twist. The other two methods do not involve twisting the

radius arms and so can be used on later axles.

METHOD:

As we are going to measure the angle between

the kingpins and the vertical, it is essential that the chassis is absolutely

horizontal. Jack up the front of the car and remove one front wheel starting

with the offside front as itís easier and will give you practice. Measure the

height of the hub/centre of the rear wheel sitting firmly on the ground and

lower the front hub until it is exactly the same height as the rear so ensuring

the chassis will be horizontal and in the running mode.

As the front axle is going to be twisted it is

necessary to slacken-off the front brakes at the foot pedal screw.

Now slacken-off slightly, but donít remove, the large

nut (5/8W) at the front of the radius arm. Using a very large adjustable wrench

(or similar) twist the radius arm downwards as far as you can. Unless youíre a

heavyweight boxer or weightlifter, this will be approximately the correct 6.5o

required. Now for the tricky bit Ė holding the wrench in your left hand without

letting up the twist, tighten the large nut with your right hand (or have an

assistant) as hard as you can. Thatís it!

Obviously, the method is the same for the nearside

wheel, also twisting the radius arm downwards. Looking at the front of car, you

twist the offside arm anti-clockwise and the nearside arm clockwise. Donít

forget to re-adjust the front brakes.

MEASURING THE CASTOR

ANGLE:

You can measure the castor angle before you

start as well as afterwards. With the front wheel off and the chassis absolutely

horizontal as above, drop a plumb line down from the centre of the hub, place a

long straight edge down the front, inner face of the hub and measure the offset

on the floor. I made a chart on the back of a Kelloggís cereal box beforehand.

This is the table of values of the offset:

FEW TECHNICAL

BITS:

|

HEIGHT OF FRONT WHEEL CENTRE |

|

OFF THE GROUND WITH |

|

CAR WEIGHT ON REAR WHEEL |

|

DISPLACEMENT GIVES 6.5O

CASTOR |

|

height (ins.) |

displacement |

|

|

(ins.) |

(mm.) |

|

12.00 |

2.0 |

51 |

|

12.25 |

2.04 |

52 |

|

12.50 |

2.08 |

53 |

|

12.75 |

2.125 |

54 |

|

13.00 |

2.17 |

55 |

Twisting the radius arms is actually twisting

the front axle forward at the bottom. This, in turn, puts a strain on the front

spring which remains firmly attached to the chassis. The ideal solution is to

put a suitable wedge between the top of the front spring and the underside of

the chassis to restore the spring to its natural line. 4mm at the thick end of

the wedge will give 6 degrees. However, it seemed to me that to slacken-off the

U-bolts attaching the spring to the front of the chassis in order to knock-in

the wedge would involve raising the engine to get access to the nuts.

The other problem is that the twisted radius arms are

only held twisted by the friction of the large nuts at the front of the axle.

Members have suggested several solutions including drilling and tapping a grub

screw through the nut; but the general opinion, based on experience, is that

itís not a problem. The radius arms stay twisted just by friction (of a very

tight nut!).

CONCLUSION:

The road holding and steering stability has

been unbelievably improved. And, if it hadnít been, at least the whole operation

can be easily undone.

David (Bodger) Whetton