iming

lever. I checked the fuel level in the tank and it was a bit low, so I added a

gallon. Still no luck, so we had to abandon the trip and try to fix the car

instead.

iming

lever. I checked the fuel level in the tank and it was a bit low, so I added a

gallon. Still no luck, so we had to abandon the trip and try to fix the car

instead.I released the fuel pump input connection and blew into the fuel tank filler, with the result that fuel poured out, confirming no blockage in the fuel pipe.

I then released the output connection, took the top off the fuel pump and filled it with fuel. I put the cap back on and operated the primer without suc-cess, confirming a pump problem. The pump is only three years old so I was surprised that it had failed. I checked the diaphragm for ethanol damage or splits, but it was like new. This led me to checking the valves.

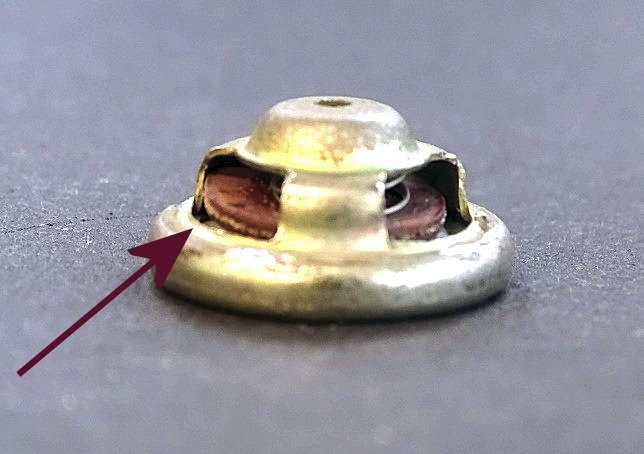

I tested the valves by blowing and sucking the respective input and output ports, having first dried them with the air line. The input valve gave no resistance. As shown in the picture, the fibre sealing washer had warped, preventing it from seating, so the pump had no suck or blow. The valves are peened to retain them in the pump body, so I gently re-moved the peened aluminium with the Dremel tool and a craft knife. I then fitted and peened to retain two new ones. Now reassembled, the pump makes that reassuring oooh-aaah sound when operated. Refitted and recon-nected, all is fine again. Now, off to Milford for that coffee.

Jon Reynolds DA7C