AC FUEL PUMP SERVICING

After the roadside assistance

given by Glyn Llewellyn to change my broken fuel pump, I dismantled my fuel pump

to repair and service it. Having bought a service kit for my Type U fuel pump

from

www.vintageandclassicspares.co.uk,

I spent a little while cleaning everything in petrol with a light brush. I

cleaned the filter gauze, although kept it as a spare and fitted a new one Iíd

bought. I cleaned the fuel inlet sediment chamber and all of the base. I didnít

find how to remove the pump lever, but there was no slack in it so I was happy

this was OK. There are many different fuel pumps around, but the Austin fuel

pumps have a longer pump lever arm, which is normally marked with 856955 with

the correct lever ending in a double digit! The lever arm on my pump looks to

have been fabricated from plate and doesnít have any markings though.

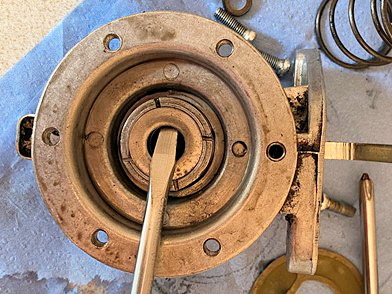

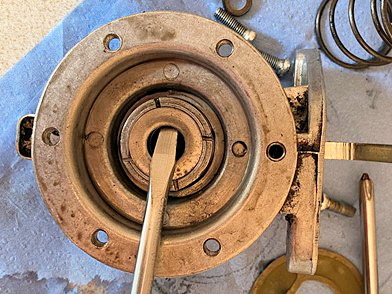

I removed the metal retainer

for the fuel pump seal in the base that the diaphr agm

pull rod moves through, by levering it out carefully from the top with a

screwdriver. I fitted the new rubber fuel pump seal in the base that the

diaphragm pull rod moves through and fitted the metal retaining disc back over

it and using an old screwdriver, re-staked the casting face to retain the disc.

agm

pull rod moves through, by levering it out carefully from the top with a

screwdriver. I fitted the new rubber fuel pump seal in the base that the

diaphragm pull rod moves through and fitted the metal retaining disc back over

it and using an old screwdriver, re-staked the casting face to retain the disc.

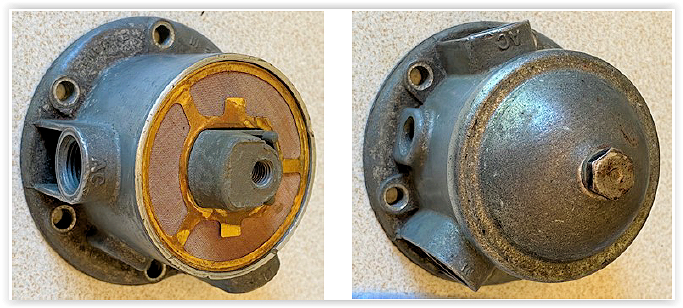

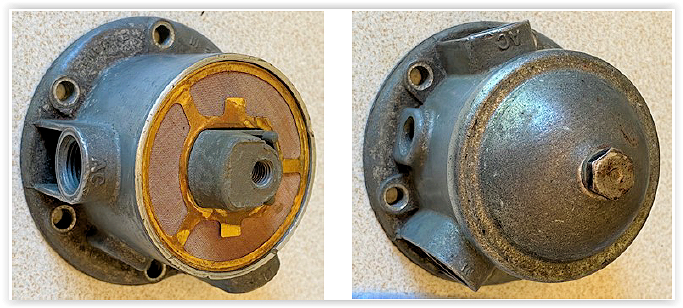

For fitt ing

the fuel valves in the upper body, there is a paper gasket (on my Type U, called

a spectacle gasket), and it is recommended using a thread locking/retaining

compound on the screws for the valve retaining bracket. I used Loctite 222,

which I had available.

ing

the fuel valves in the upper body, there is a paper gasket (on my Type U, called

a spectacle gasket), and it is recommended using a thread locking/retaining

compound on the screws for the valve retaining bracket. I used Loctite 222,

which I had available.

It appears there is a good variety

of shapes for the valve retaining bracket Ė mine was H-shaped but others are

triangular. Similarly the valve gaskets vary in shape and size.

Refitting the gauze and making sure

this

was

sitting within the body and sub-flush, I fitted the domed cover with a new

washer and fitted the retaining screw with a new fibre washer. It is important

not to tighten the dome retaining screw on the top too much because it is easy

to strip the thread in the casting body. Alternatively, a stud can be fitted in

to the body fully, preventing the thread from stripping and a nut used outside

to retain the domed cover. My pump had the screw, which I carefully tightened

and I retightened it slightly a few days later after it had been run on the

engine.

was

sitting within the body and sub-flush, I fitted the domed cover with a new

washer and fitted the retaining screw with a new fibre washer. It is important

not to tighten the dome retaining screw on the top too much because it is easy

to strip the thread in the casting body. Alternatively, a stud can be fitted in

to the body fully, preventing the thread from stripping and a nut used outside

to retain the domed cover. My pump had the screw, which I carefully tightened

and I retightened it slightly a few days later after it had been run on the

engine.

Fitting the spring and diaphragm is

a bit tricky and probably needs a few attempts and, ideally, about 6 hands!

Aligning the pull-rod end with the slot in the base and noting the position of

the diaphragm to know how far to turn in, carefully slide the pull rod through

the new rubber oil seal and push down on the diaphragm against the spring

pressure and turn it through 90 degrees. Pushing the pump lever away from the

pump body will reduce the spring compression needed. The diaphragm pull-rod will

be retained and locked in. Align the diaphragm holes around the edge

approximately with the screw holes in the body. Fit the two halves of the fuel

pump together and fit the six screws very loosely. Pull the pump lever towards

the body to depress the diaphragm to the most stretched position and then

tighten the 6 screws uniformly tightening in turn screws opposite each other.

Once assembled, moving the pump level should result in a croaking noise.

Fit a new paper gasket to the

crankcase mounting face if needed and slide the pump lever pointing upwards into

the hole on the crankcase ensuring the lever is just inside the crankcase and

outside the camshaft. Once bolted in, turn the starter handle by hand a few

times to ensure the pump lever is in the correct position and the engine doesnít

lock up. Refit the fuel lines and, hopefully, all will work when started.

When I examined the removed

diaphragm of my pump, it appeared intact and the only thing I could find wrong

with the pump was possibly one of the fuel valve fibre washers had moved

slightly sideways and wasnít seating properly and therefore not sealing

correctly. Having fitted the pump, all seems to be working as expected with no

fuel or oil leaks. Although the three pumps I have are all marked as ĎType Uí,

they are each slightly different, so if you are servicing your pump you may need

to research the parts needed. For example, my pump didnít have a drain screw in

the upper fuel chamber to allow debris to be removed, which most seem to have.

Happy motoring. Nick Kidd DA7C

agm

pull rod moves through, by levering it out carefully from the top with a

screwdriver. I fitted the new rubber fuel pump seal in the base that the

diaphragm pull rod moves through and fitted the metal retaining disc back over

it and using an old screwdriver, re-staked the casting face to retain the disc.

agm

pull rod moves through, by levering it out carefully from the top with a

screwdriver. I fitted the new rubber fuel pump seal in the base that the

diaphragm pull rod moves through and fitted the metal retaining disc back over

it and using an old screwdriver, re-staked the casting face to retain the disc.

ing

the fuel valves in the upper body, there is a paper gasket (on my Type U, called

a spectacle gasket), and it is recommended using a thread locking/retaining

compound on the screws for the valve retaining bracket. I used Loctite 222,

which I had available.

ing

the fuel valves in the upper body, there is a paper gasket (on my Type U, called

a spectacle gasket), and it is recommended using a thread locking/retaining

compound on the screws for the valve retaining bracket. I used Loctite 222,

which I had available. was

sitting within the body and sub-flush, I fitted the domed cover with a new

washer and fitted the retaining screw with a new fibre washer. It is important

not to tighten the dome retaining screw on the top too much because it is easy

to strip the thread in the casting body. Alternatively, a stud can be fitted in

to the body fully, preventing the thread from stripping and a nut used outside

to retain the domed cover. My pump had the screw, which I carefully tightened

and I retightened it slightly a few days later after it had been run on the

engine.

was

sitting within the body and sub-flush, I fitted the domed cover with a new

washer and fitted the retaining screw with a new fibre washer. It is important

not to tighten the dome retaining screw on the top too much because it is easy

to strip the thread in the casting body. Alternatively, a stud can be fitted in

to the body fully, preventing the thread from stripping and a nut used outside

to retain the domed cover. My pump had the screw, which I carefully tightened

and I retightened it slightly a few days later after it had been run on the

engine.