A7 LUBRICATION - THE

COMPLETE GUIDE

For the Austin Seven the following Lubricants are

approved by Austin Motors:—

Engine ..

CASTROL XL.

Gear Box ..

CASTROL XL.

Rear Axle..

CASTROL "D" Gear Oil.

Wheel Hubs

Wakefield CASTROLEASE Medium.

Universal Joint ..

CASTROL UNIJOYNT.

Chassis Grease

CASTROLEASE Medium.

Gun Nipples

CASTROLEASE Medium.

Electrical Equipment

Wakefield OILIT.

Above are outlined the units which require periodical

attention. These are dealt with separately in the following paragraphs, which

deal with every detail of the Austin Seven Lubrication requirements.

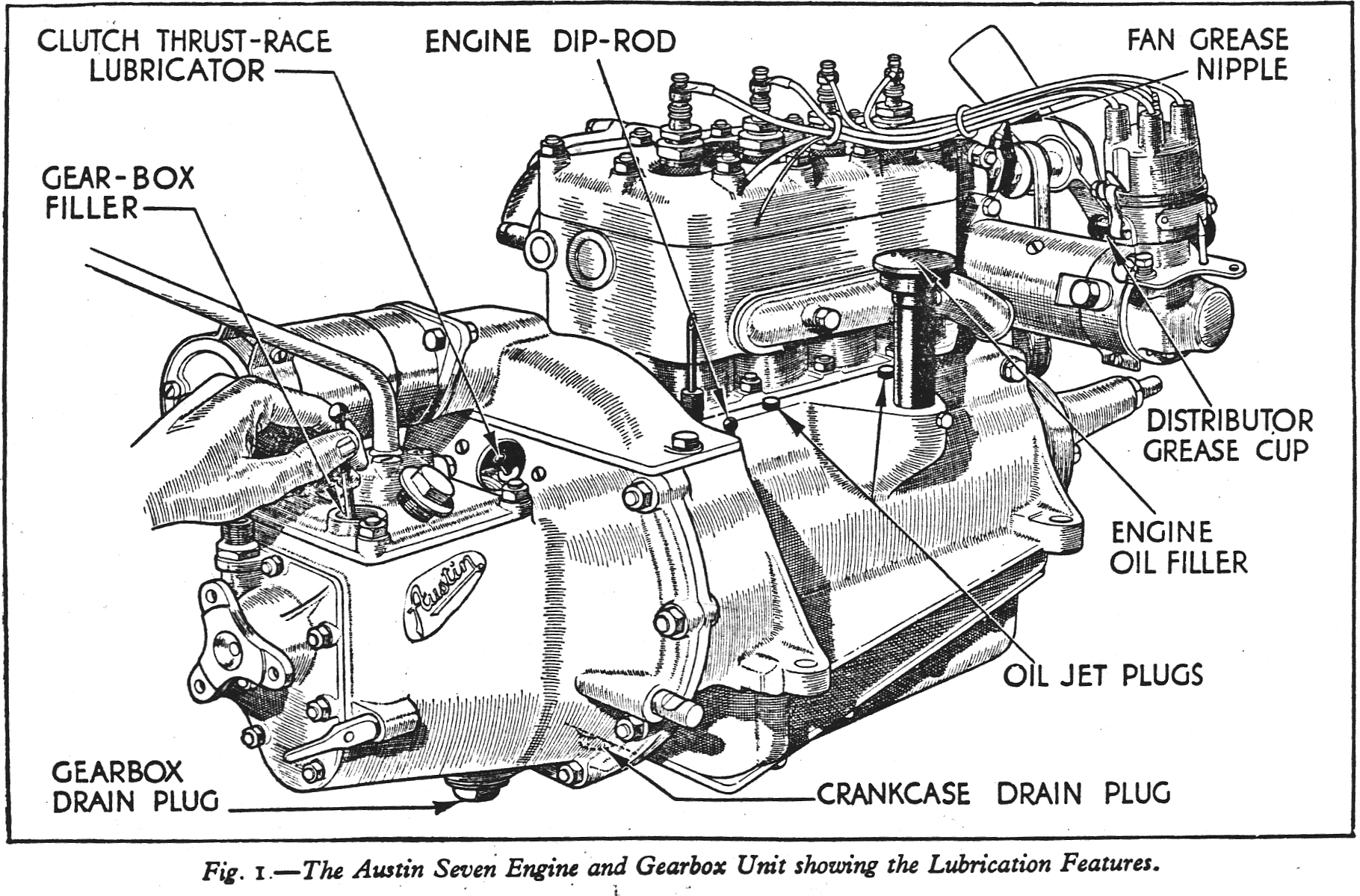

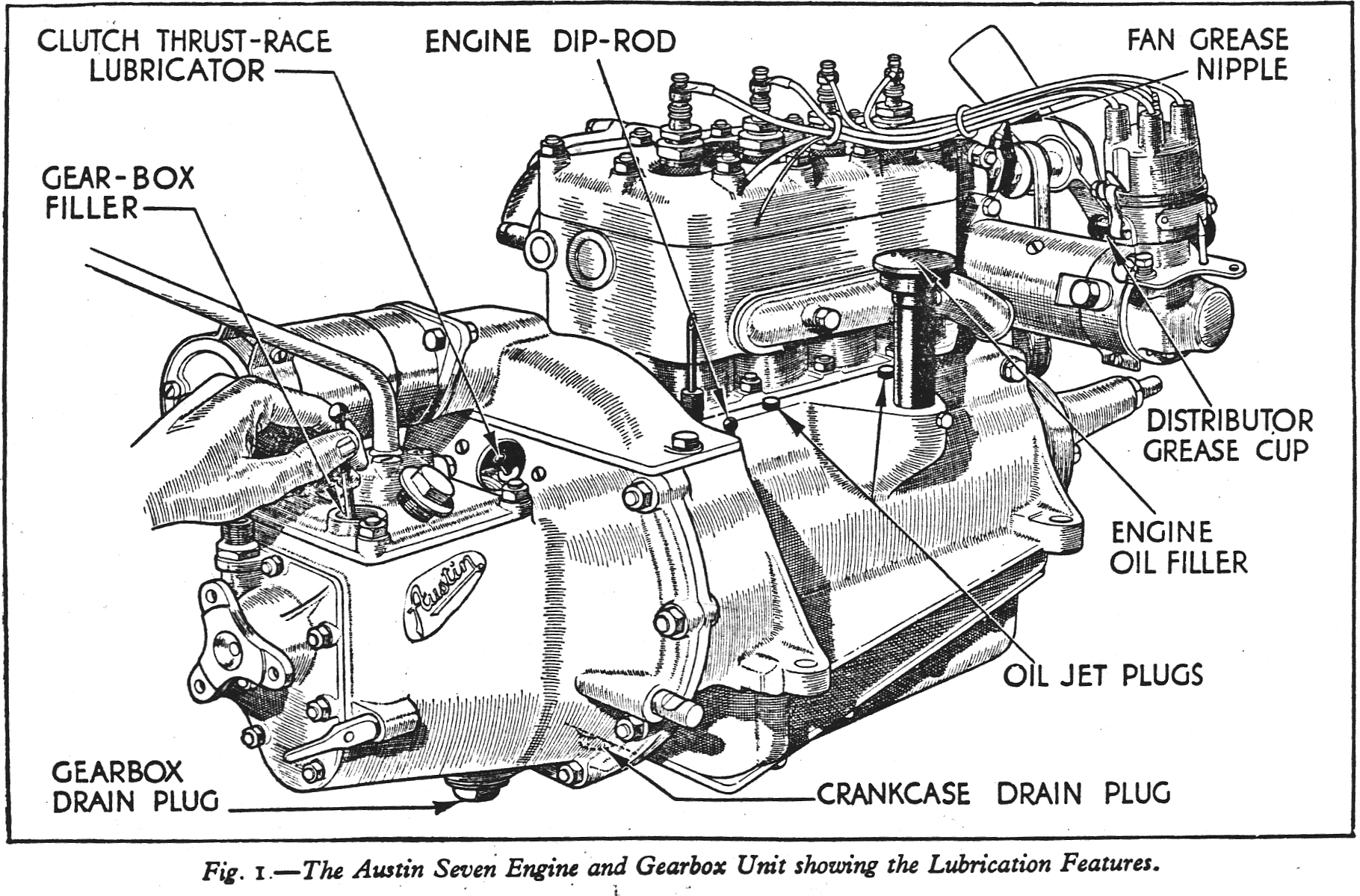

Engine

Before

starting the engine each day, check the oil level in the sump by means of the

dip-rod provided, and add CASTROL XL until oil reaches the "full" mark on the

rod (Fig. I). When your Austin Seven is new the crankcase should be drained

after the first 500 miles running and replenished with fresh oil.

How to Drain the Crankcase.

Whilst the oil is still warm after a run

remove the drain plug situated beneath the crankcase (Fig. 1) and allow the oil

to drain off completely, then replace the plug and refill with fresh oil of

correct grade as above.

Changing the Oil.

Because even the best oil tends to

become contaminated and diluted with fuel after it has been in use some time,

it is necessary to drain the crankcase every 1,000 miles after the first 500,

and replenish with fresh oil.

Cleaning The Oil Reservoir.

It is advisable every 3,000 miles to

remove the lower half of the crankcase (or oil reservoir). The gauze oil tray

will then be accessible. This should be removed and together with the oil

reservoir scrupulously cleaned with paraffin or petrol. When replacing,

carefully remake the oil-tight joint with the packing washer which should be

covered with grease on both sides.

Oil Flow Indicator.

This is situated on the Instrument

Board, and when the engine is running the button should always protrude under

pressure of oil. If the button fails to protrude the engine -should be

immediately stopped and the cause ascertained.

Oil Jets.

Lubrication of the big ends is effected

by oil forced from jets incorporated in the crankcase webs above the crankshaft.

Every 1,000 miles use this method to ensure that the jets are clean: Remove the

plugs situated over these jets and protruding above the cylinder head water

jacket, and insert a stiff piece of wire not exceeding 1/16 in. diameter through

the jets. Two of these plugs appear in Fig. 1, which illustrates their

accessibility for this operation.

The Clutch.

Every 250

miles apply three or four drops of CASTROL XL to the clutch thrust race. To

reach this swing back the oval clutch cover plate after loosening retaining

screws (See Fig. I).

It is well to remember that the clutch surfaces being

of fabric material must be kept free from oil and grease, or clutch slip will

soon be in evidence. For this reason, care should be exercised when applying oil

to the thrust race.

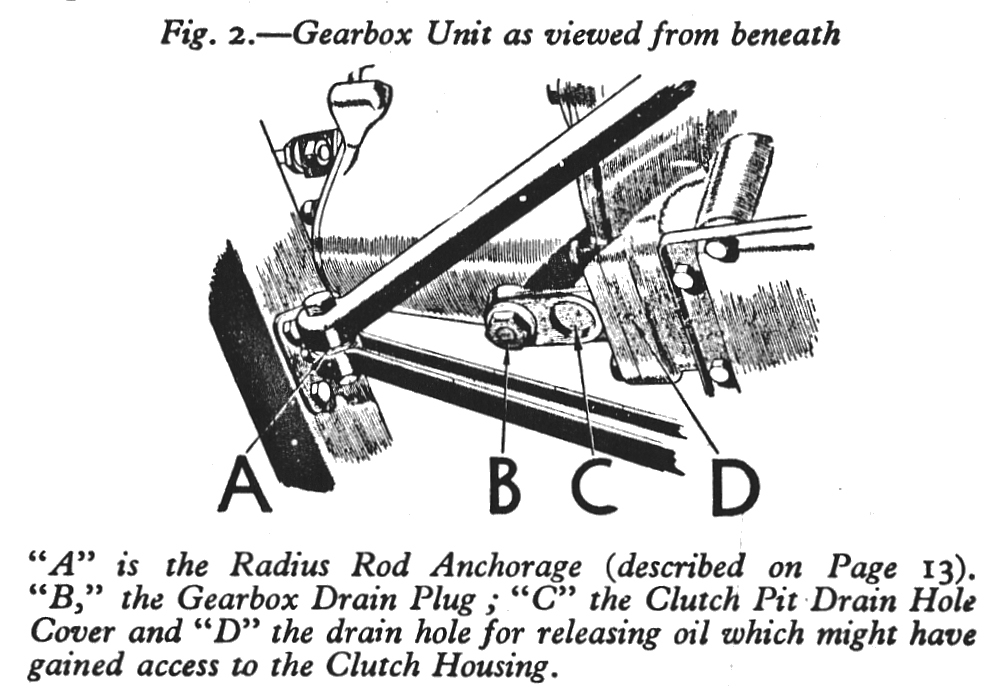

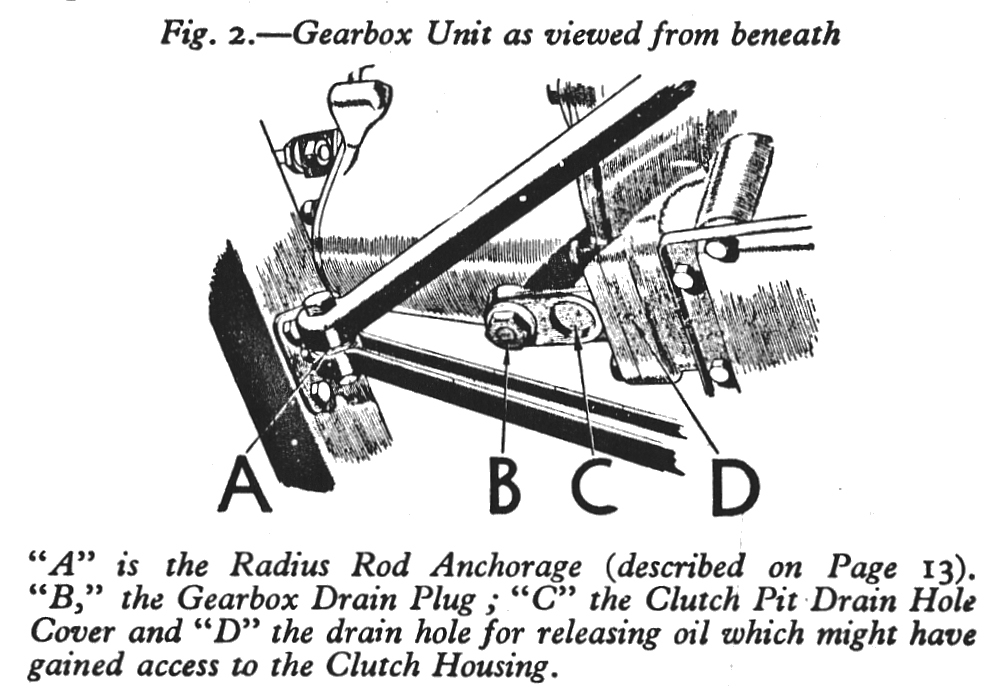

Gear Box.

When

your Austin Seven is new the gear box should be completely drained after the

first 500 miles running. To do this remove the gear box drain plug (the position

of which is shown in Fig. t) whilst oil is still warm after a run. This drain

plug also holds the clutch pit drain hole cover in position as illustrated in

Fig. 2, and when refitting the drain plug this must be replaced.

When

your Austin Seven is new the gear box should be completely drained after the

first 500 miles running. To do this remove the gear box drain plug (the position

of which is shown in Fig. t) whilst oil is still warm after a run. This drain

plug also holds the clutch pit drain hole cover in position as illustrated in

Fig. 2, and when refitting the drain plug this must be replaced.

After draining, about two-thirds of a pint of CASTROL

XL is the maximum quantity required for complete replenishment of the gear box.

The amount of oil in the gear box can be checked by inserting the engine

dip-stick in the gear box filling orifice (Fig. 1). The depth of oil should

never be less than one inch or more than two and a half inches. It is advisable

to check this every 1,000 miles and maintain at the maximum level by

replenishing with CASTROL XL.

Changing the Oil.

Every 5,000 miles after the first 500

repeat the draining process previously described and refill with CASTROL XL.

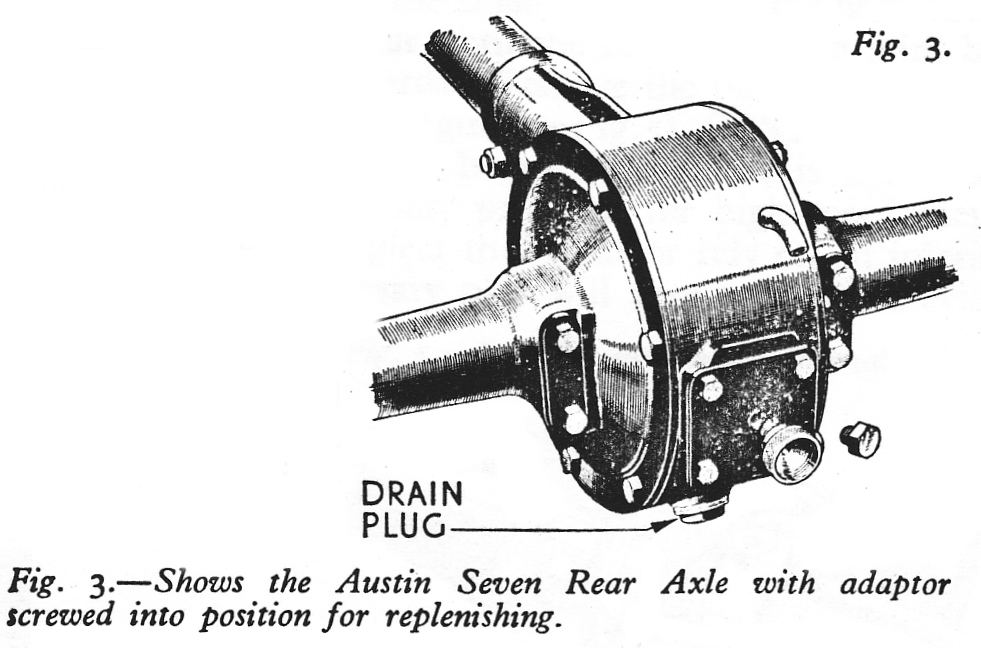

Rear Axle.

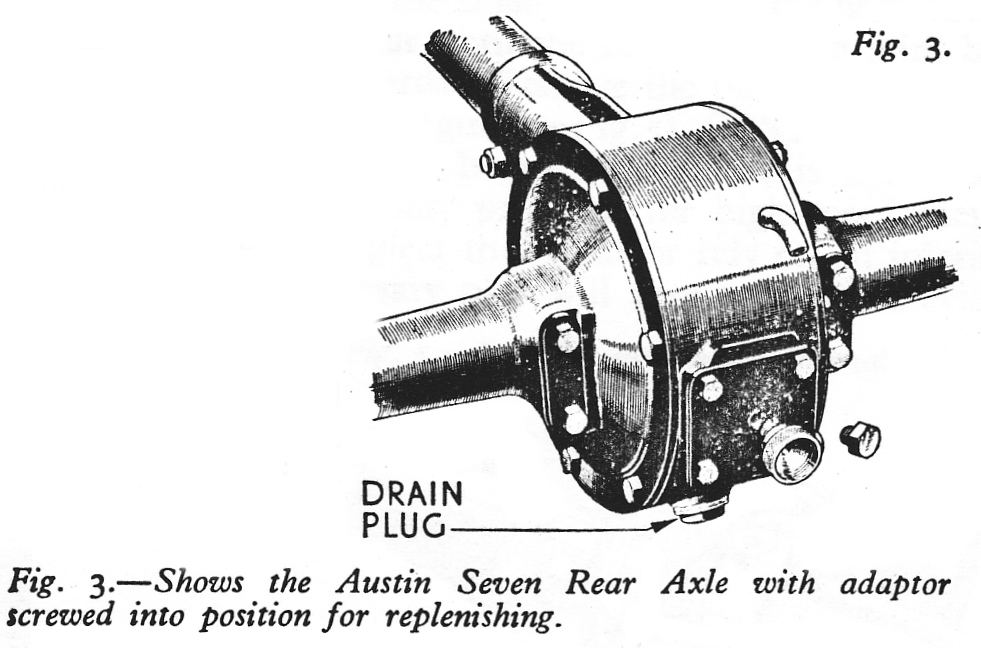

The

rear axle should be replenished every 1,000 miles with CASTROL "D" Gear Oil. To

do this, first remove the plug situated at the rear of the axle centre casing

(Fig. 3). Then screw the end of the grease gun adaptor into the hole, attach the

barrel of the grease gun and force in lubricant. Do not inject too much at any

one time, as oil is liable to reach the brake shoes and impair their

efficiency.

The

rear axle should be replenished every 1,000 miles with CASTROL "D" Gear Oil. To

do this, first remove the plug situated at the rear of the axle centre casing

(Fig. 3). Then screw the end of the grease gun adaptor into the hole, attach the

barrel of the grease gun and force in lubricant. Do not inject too much at any

one time, as oil is liable to reach the brake shoes and impair their

efficiency.

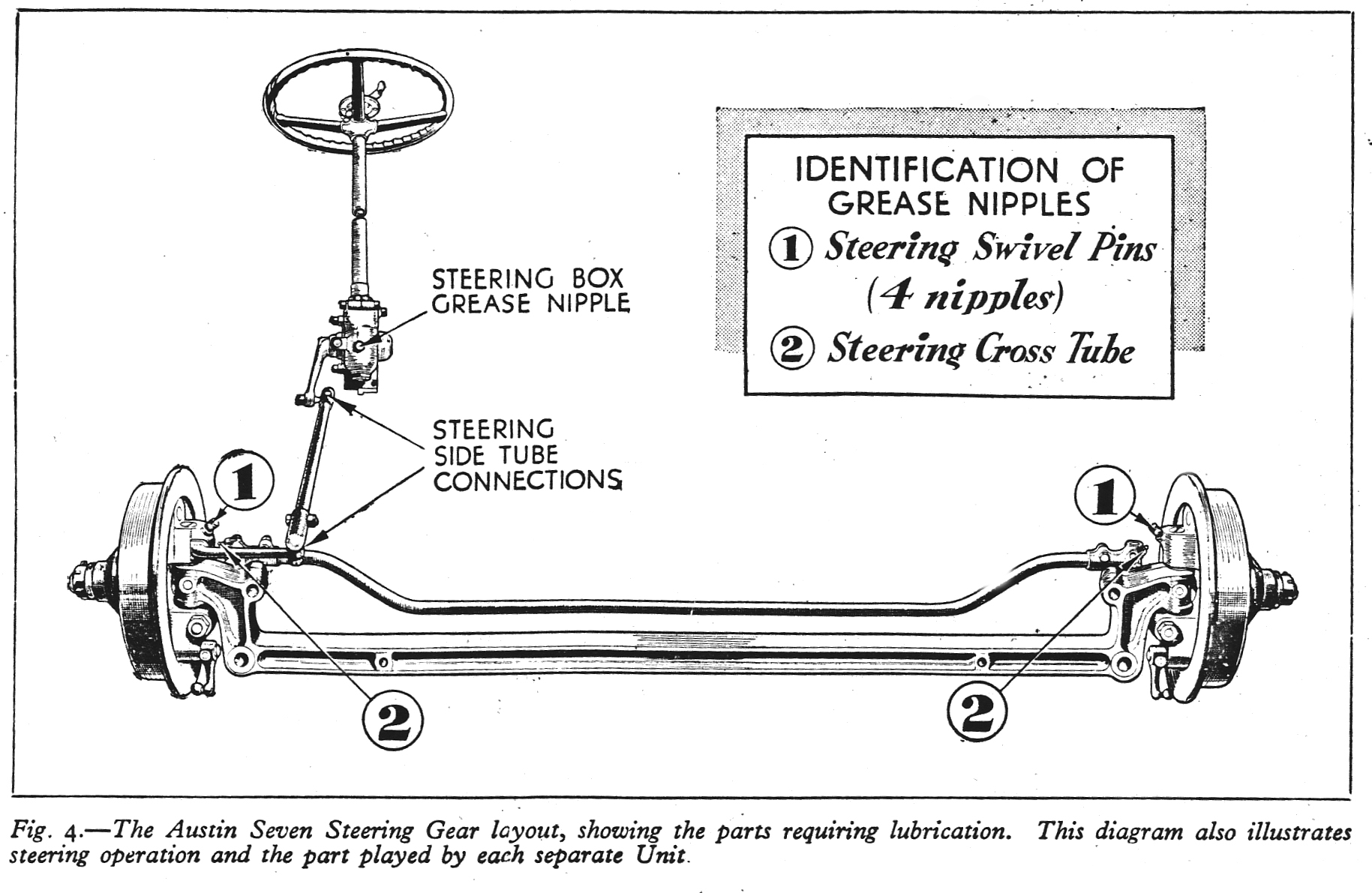

Steering Gear.

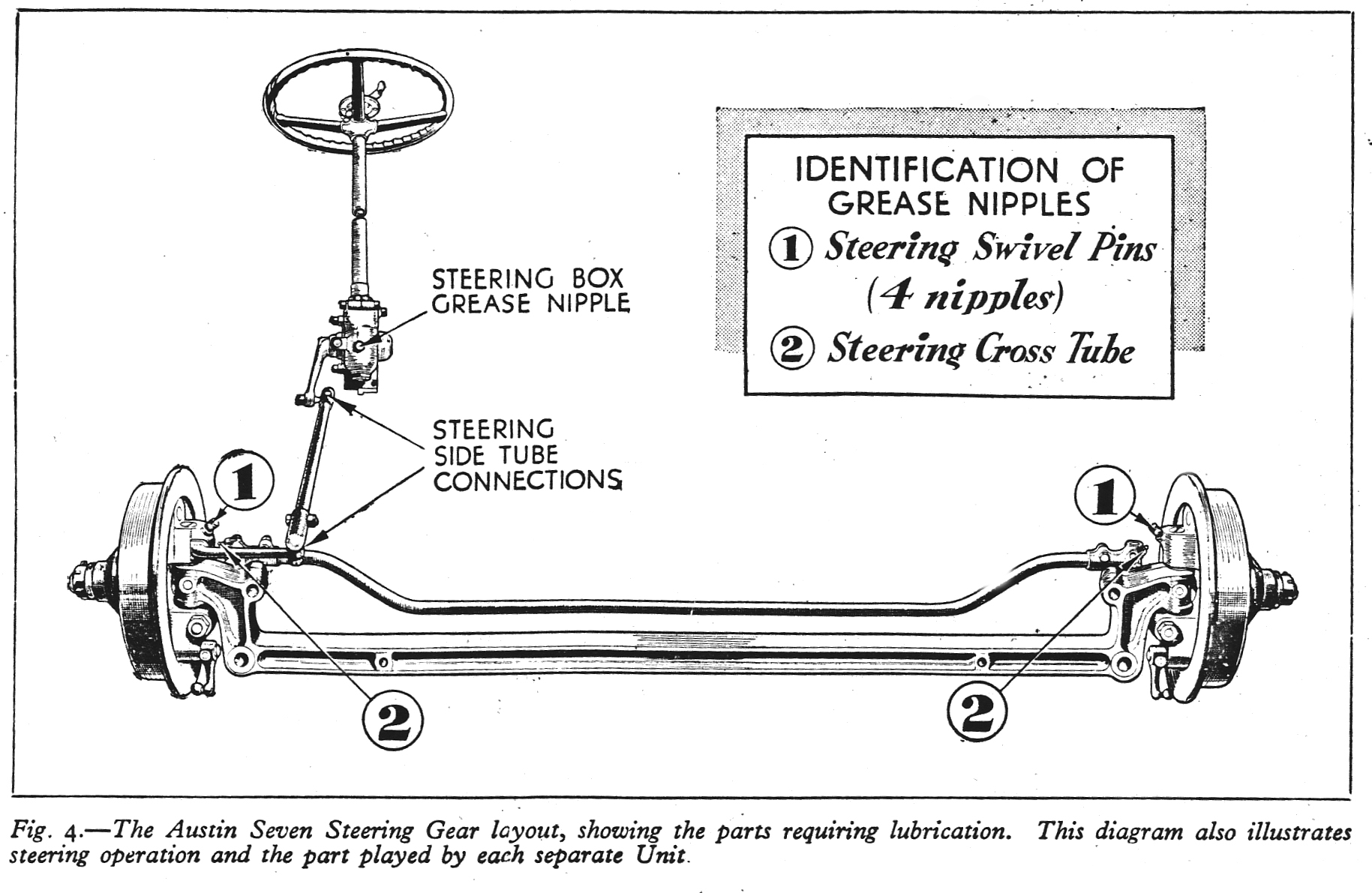

In order

to enjoy ease of steering and eliminate the possibility of "play" developing

between the steering wheel and road wheels through wear, regular lubrication at

all points of the steering gear is essential. The parts mentioned below can be

located by reference to Fig. 4

Steering

Gear Box.

Steering

Gear Box.

Every 1,000 miles give a charge of

Wakefield CASTROLEASE Medium with the grease gun at the nipple situated on top

of the box. This will lubricate the worm and worm wheel bearings.

Steering Column.

Give bearing at top of the steering

column a little oil from the oilcan every 250 miles.

Steering Side Tube.

Every 250 miles the steering connections

on this should be lubricated with CASTROL XL using an oilcan which injects the

lubricant under pressure into the sockets.

Steering Swivel Pins and Cross Tube.

Every 250 miles apply Wakefield

CASTROLEASE Medium with the grease gun at the nipples provided (there are four

of these in all).

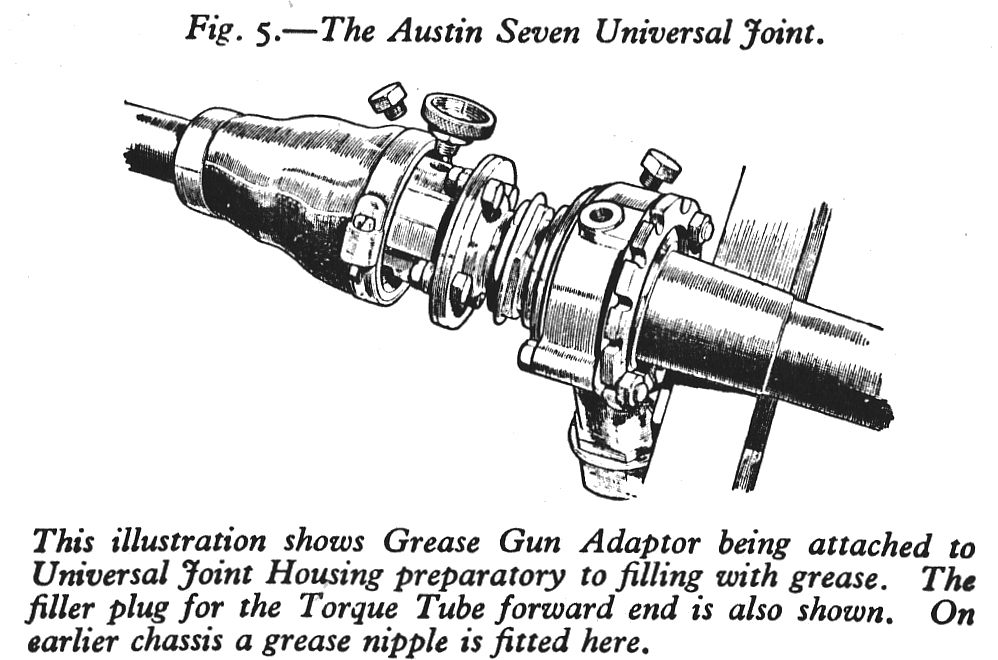

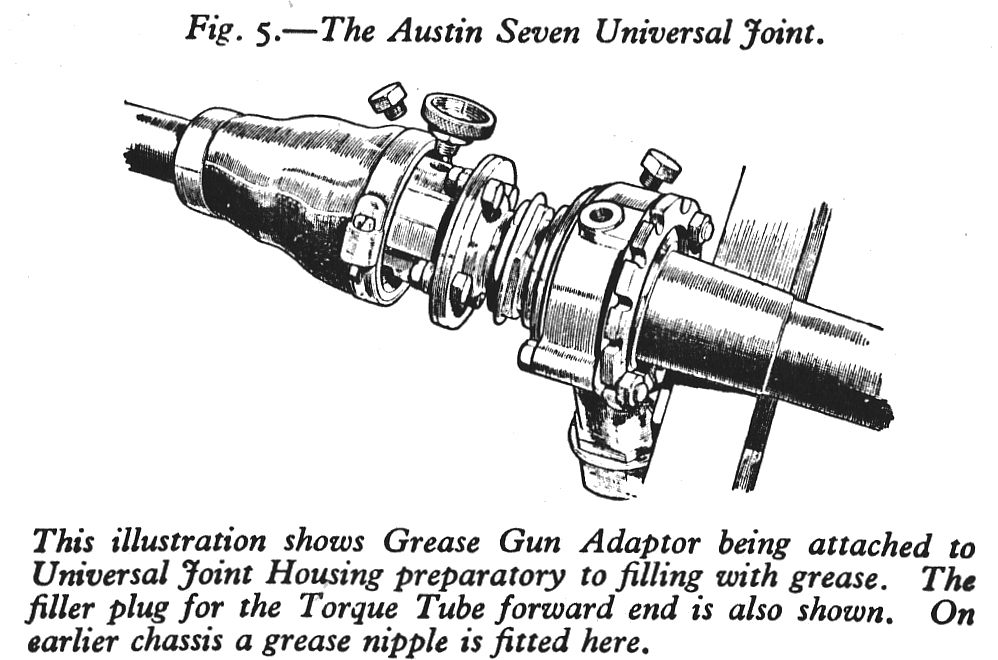

Universal Joint.

Every

250 miles fill the joint housing with CASTROL UNIJOYNT Grease. To reach this

point move aside the small cover in the car floor board. Now move the car until

the filling plug on joint housing is facing upwards. Remove the plug and apply

lubricant with the grease gun (see Fig. 5). CASTROL UNI JOYNT should always be

used here. It is a non-separating grease specially prepared for high-speed metal

joints. Do not neglect this point or rely on an inferior grease or unnecessary

play will very soon be in evidence.

Every

250 miles fill the joint housing with CASTROL UNIJOYNT Grease. To reach this

point move aside the small cover in the car floor board. Now move the car until

the filling plug on joint housing is facing upwards. Remove the plug and apply

lubricant with the grease gun (see Fig. 5). CASTROL UNI JOYNT should always be

used here. It is a non-separating grease specially prepared for high-speed metal

joints. Do not neglect this point or rely on an inferior grease or unnecessary

play will very soon be in evidence.

Just to the rear of the Universal joint is another

filling plug (or on the earlier model a grease nipple) for lubricating the

forward end of the torque tube. Apply Wakefield CASTROLEASE Medium here, using

the special adaptor if a filling plug is fitted.

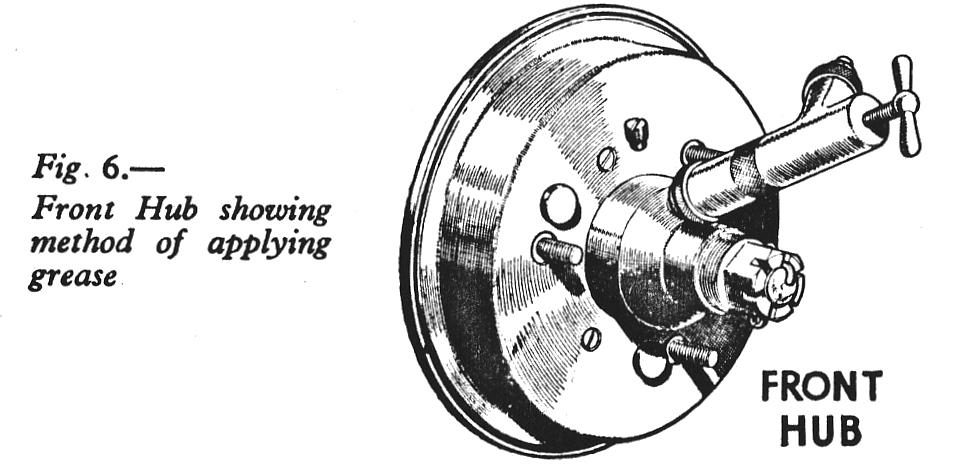

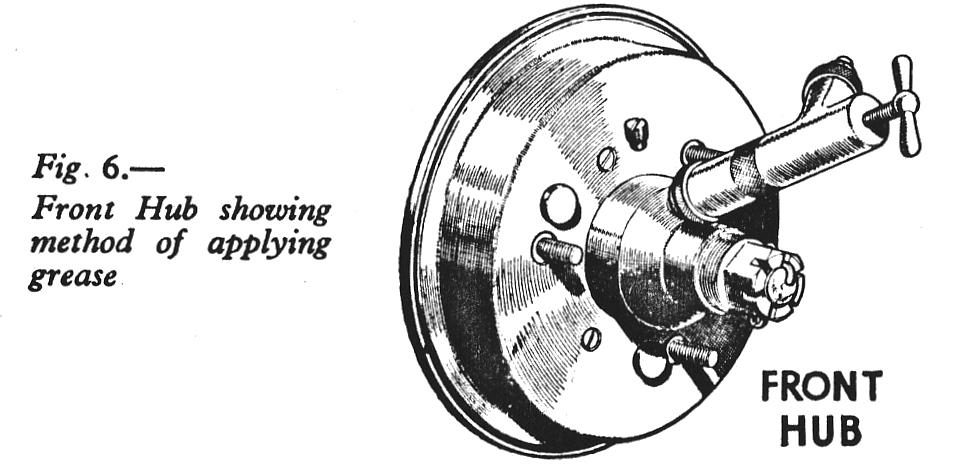

Wheel Bearings.

From

Hubs.

From

Hubs.

Every 1,000 miles remove road wheel and

turn the hub until the filling plug is at the top. Now remove the plug and screw

in the special adaptor provided in the tool kit. Apply six strokes of the grease

gun filled with Wakefield CASTROLEASE Medium (see Fig. 6). Do not forget to

replace the filling plug after detaching the grease gun.

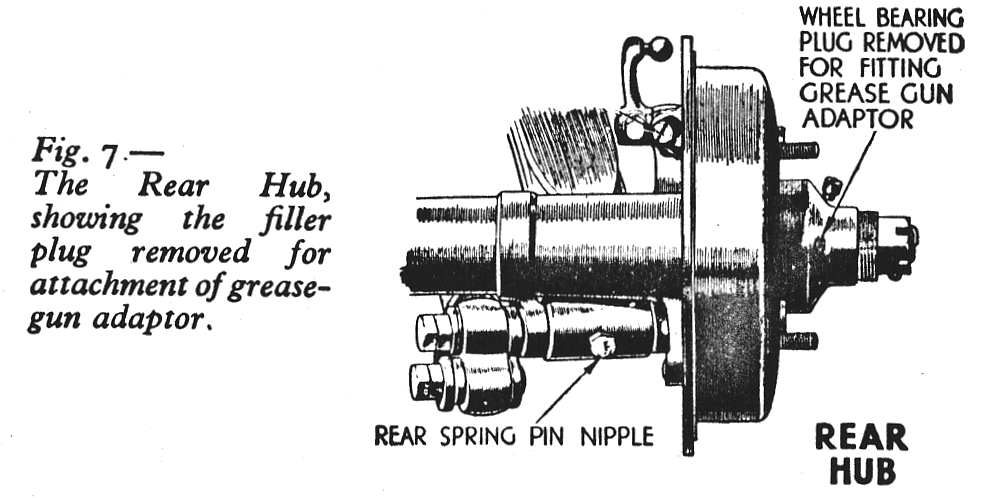

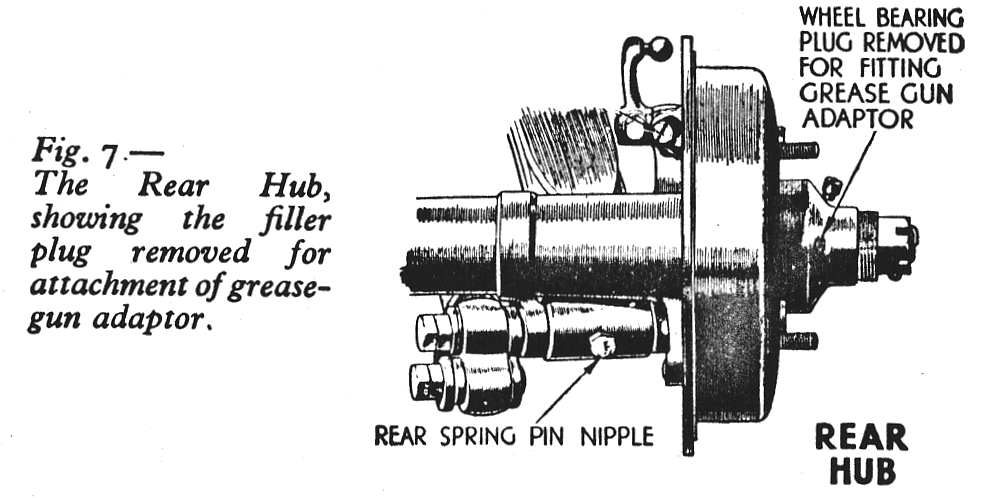

Rear Hubs.

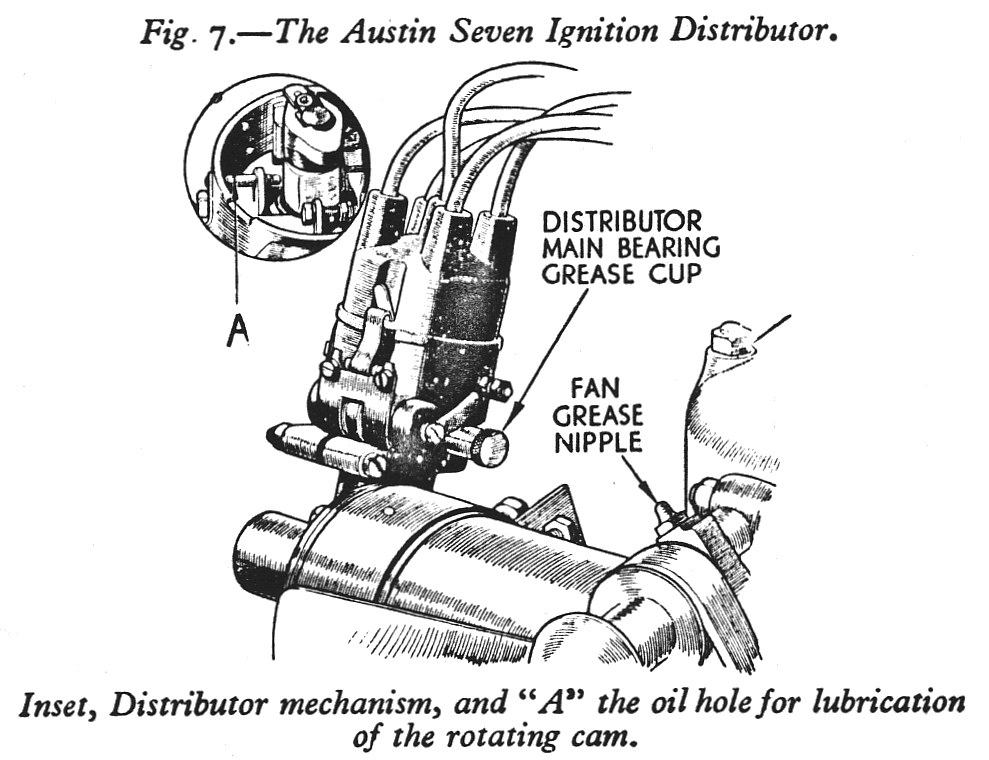

Lubrication

of the Rear Hubs should be carried out in the same manner as for front hubs. In

some instances, however, a grease nipple is fitted in place of the filling plug

shown in Fig. 7 below. When this is the case the screw-in adaptor will not, of

course, be necessary.

Lubrication

of the Rear Hubs should be carried out in the same manner as for front hubs. In

some instances, however, a grease nipple is fitted in place of the filling plug

shown in Fig. 7 below. When this is the case the screw-in adaptor will not, of

course, be necessary.

Brake Gear.

Cam Spindles.

Each rear brake cam spindle is provided

with an oil-less bush which does not require lubrication. No attention is

therefore necessary at these points. Front brake cam spindles are

lubricated from the swivel pin and require no separate attention.

Brake Joints.

Every 250 miles apply the oilcan to keep

the brake gear efficient and easy in operation.

Suspension Springs.

Spring Anchorages and Spring Shackle Pins.

These are all provided with easily

accessible grease gun nipples to which CASTROLEASE Medium should be injected

with the grease gun every 250 miles. There are six nipples in all. The one

fitted to the offside rear spring anchorage is illustrated in Fig. 7.

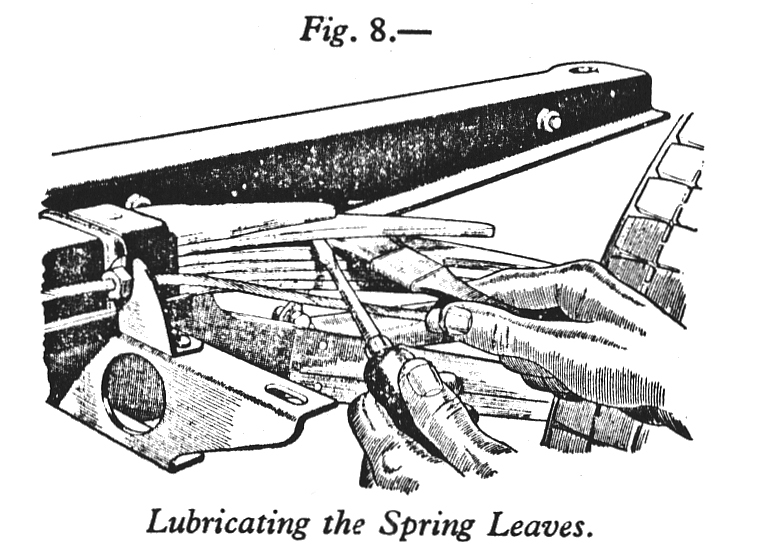

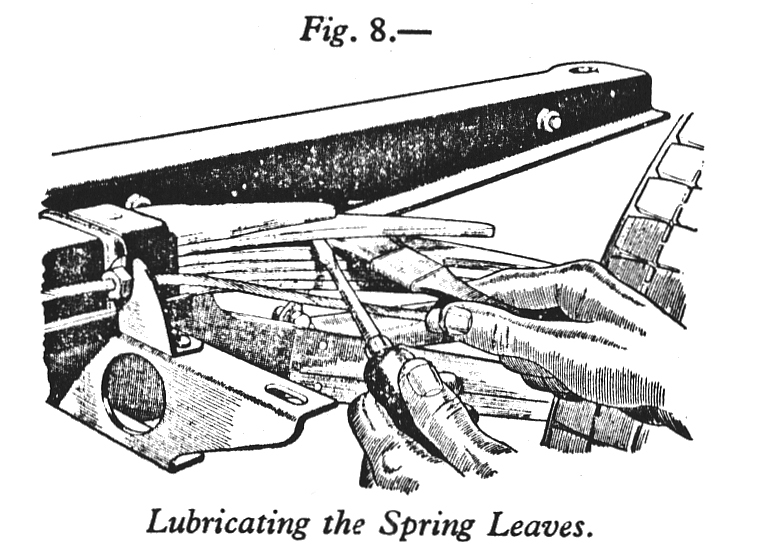

Spring Leaves.

Every

10,000 miles it is necessary to lubricate these. In order to do this the weight

of the car must be taken off the springs and the spring leaves prised apart with

a screwdriver or similar instrument. To take the weight off the front spring

place the jack under the short cross-member just forward of the engine. The jack

should be standing on a wood block for this purpose. The rear springs may be

attended to one side at a time by jacking the car beneath either end of rear

crossmember. Having prised the spring leaves apart, apply Wakefield CASTROLEASE

"G" with a stiff brush between them. This operation is illustrated in Fig. 8.

Every

10,000 miles it is necessary to lubricate these. In order to do this the weight

of the car must be taken off the springs and the spring leaves prised apart with

a screwdriver or similar instrument. To take the weight off the front spring

place the jack under the short cross-member just forward of the engine. The jack

should be standing on a wood block for this purpose. The rear springs may be

attended to one side at a time by jacking the car beneath either end of rear

crossmember. Having prised the spring leaves apart, apply Wakefield CASTROLEASE

"G" with a stiff brush between them. This operation is illustrated in Fig. 8.

Radius Rod Anchorage.

The radius rods are anchored by means of

a ball flange and cups attached to the front crossmember just below rear end of

the gear box. Every 1,000 miles a few drops of engine oil should be applied at

this point. This is illustrated in Fig. 2.

Fan Bearing.

A nipple is fitted to this unit to which CASTROLEASE

Medium should be applied every 250 miles with the grease gun. This nipple is

shown in the top right-hand corner of Fig. 1.

Electrical Equipment.

Dynamo.

The dynamo bearings are packed with grease before

leaving the works and require very little attention. Every 1,000 miles, however,

add three drops of Wakefield OILIT through the lubricator near the mounting

flange (Fig. 1). It is well to note that far more trouble is caused by excessive

oiling than by too little.

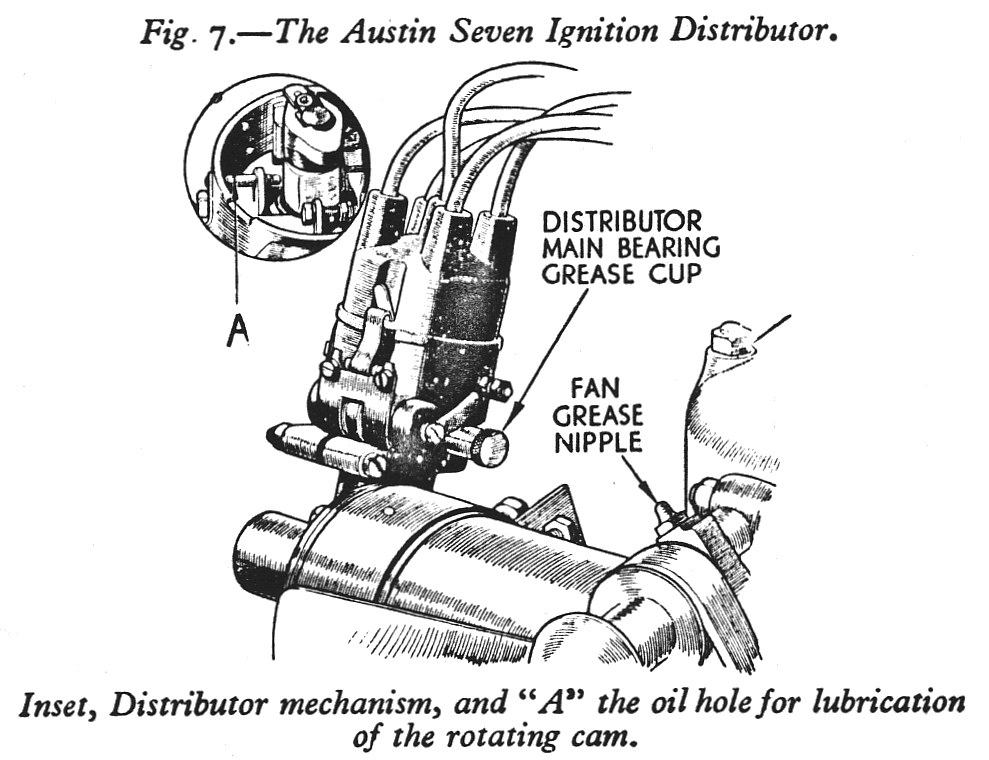

Distributor.

Every

5oo miles give the grease cup two turns. This will lubricate the Distributor

main bearing. This grease cup should be filled with Wakefield CASTROLEASE

Medium. At the same mileage interval apply two drops of Wakefield OILIT to the

cam lubrication wick through the hole provided (see Fig. 9). Take care not to

over lubricate these parts.

Every

5oo miles give the grease cup two turns. This will lubricate the Distributor

main bearing. This grease cup should be filled with Wakefield CASTROLEASE

Medium. At the same mileage interval apply two drops of Wakefield OILIT to the

cam lubrication wick through the hole provided (see Fig. 9). Take care not to

over lubricate these parts.

Windshield Wiper.

Every 1,000 miles apply a drop of

Wakefield OILIT to screen wiper mechanism. Except on the Trico model, a small

screw can be removed from the top of the casing to permit the oil to be

injected.

Starting Motor.

This Unit requires very little attention

as the bearings are packed with grease before leaving the works. Occasionally

remove the clip-secured commutator cover and inspect the commutator. This should

be kept free from oil, brush dust, etc., by the application of a soft cloth to

its surface whilst the spindle is slowly turned.

Also Requiring Attention.

Every

1,000 miles make a point of going round your Austin Seven and applying a few

drops of Wakefield OILIT to the carburettor and ignition control rod joints,

door hinges, bonnet fasteners, etc. It is a good plan, too, after nuts or screws

have been removed for any purpose, to apply a drop of oil before replacing

these.

When

your Austin Seven is new the gear box should be completely drained after the

first 500 miles running. To do this remove the gear box drain plug (the position

of which is shown in Fig. t) whilst oil is still warm after a run. This drain

plug also holds the clutch pit drain hole cover in position as illustrated in

Fig. 2, and when refitting the drain plug this must be replaced.

When

your Austin Seven is new the gear box should be completely drained after the

first 500 miles running. To do this remove the gear box drain plug (the position

of which is shown in Fig. t) whilst oil is still warm after a run. This drain

plug also holds the clutch pit drain hole cover in position as illustrated in

Fig. 2, and when refitting the drain plug this must be replaced. The

rear axle should be replenished every 1,000 miles with CASTROL "D" Gear Oil. To

do this, first remove the plug situated at the rear of the axle centre casing

(Fig. 3). Then screw the end of the grease gun adaptor into the hole, attach the

barrel of the grease gun and force in lubricant. Do not inject too much at any

one time, as oil is liable to reach the brake shoes and impair their

efficiency.

The

rear axle should be replenished every 1,000 miles with CASTROL "D" Gear Oil. To

do this, first remove the plug situated at the rear of the axle centre casing

(Fig. 3). Then screw the end of the grease gun adaptor into the hole, attach the

barrel of the grease gun and force in lubricant. Do not inject too much at any

one time, as oil is liable to reach the brake shoes and impair their

efficiency. Steering

Gear Box.

Steering

Gear Box. Every

250 miles fill the joint housing with CASTROL UNIJOYNT Grease. To reach this

point move aside the small cover in the car floor board. Now move the car until

the filling plug on joint housing is facing upwards. Remove the plug and apply

lubricant with the grease gun (see Fig. 5). CASTROL UNI JOYNT should always be

used here. It is a non-separating grease specially prepared for high-speed metal

joints. Do not neglect this point or rely on an inferior grease or unnecessary

play will very soon be in evidence.

Every

250 miles fill the joint housing with CASTROL UNIJOYNT Grease. To reach this

point move aside the small cover in the car floor board. Now move the car until

the filling plug on joint housing is facing upwards. Remove the plug and apply

lubricant with the grease gun (see Fig. 5). CASTROL UNI JOYNT should always be

used here. It is a non-separating grease specially prepared for high-speed metal

joints. Do not neglect this point or rely on an inferior grease or unnecessary

play will very soon be in evidence. From

Hubs.

From

Hubs.

Every

10,000 miles it is necessary to lubricate these. In order to do this the weight

of the car must be taken off the springs and the spring leaves prised apart with

a screwdriver or similar instrument. To take the weight off the front spring

place the jack under the short cross-member just forward of the engine. The jack

should be standing on a wood block for this purpose. The rear springs may be

attended to one side at a time by jacking the car beneath either end of rear

crossmember. Having prised the spring leaves apart, apply Wakefield CASTROLEASE

"G" with a stiff brush between them. This operation is illustrated in Fig. 8.

Every

10,000 miles it is necessary to lubricate these. In order to do this the weight

of the car must be taken off the springs and the spring leaves prised apart with

a screwdriver or similar instrument. To take the weight off the front spring

place the jack under the short cross-member just forward of the engine. The jack

should be standing on a wood block for this purpose. The rear springs may be

attended to one side at a time by jacking the car beneath either end of rear

crossmember. Having prised the spring leaves apart, apply Wakefield CASTROLEASE

"G" with a stiff brush between them. This operation is illustrated in Fig. 8.