IN these days of dependable motoring, engine failure or other derangement

enforcing a stop is comparatively rare. Tens of thousands of miles can normally

be covered without an involuntary halt. Yet perhaps it is this very immunity

which sometimes leaves the motorist unprepared when the unexpected happens, and

the car comes to rest as, in vulgar parlance, the engine "conks out." When the

engine fails, tracing the causes and effecting a remedy calls for the

application of practical experience. Close reasoning, and not a little ingenuity

may be needed, for "troubleshooting" (as our American friends call it) requires

an alert mind to comprehend quickly the many possibilities that arise. But as a

start these can, with certain exceptions, be broadly divided into fuel or

ignition defects, and, according to breakdown statistics, the odds in favour of

the latter are ten to one. That is a fact worth remembering for it may guide

investigation into the right channel at the outset. But even with such

favourable odds there is no need for diagnosis to rely entirely on chance if the

circumstances of the failure are properly taken into account.

IN these days of dependable motoring, engine failure or other derangement

enforcing a stop is comparatively rare. Tens of thousands of miles can normally

be covered without an involuntary halt. Yet perhaps it is this very immunity

which sometimes leaves the motorist unprepared when the unexpected happens, and

the car comes to rest as, in vulgar parlance, the engine "conks out." When the

engine fails, tracing the causes and effecting a remedy calls for the

application of practical experience. Close reasoning, and not a little ingenuity

may be needed, for "troubleshooting" (as our American friends call it) requires

an alert mind to comprehend quickly the many possibilities that arise. But as a

start these can, with certain exceptions, be broadly divided into fuel or

ignition defects, and, according to breakdown statistics, the odds in favour of

the latter are ten to one. That is a fact worth remembering for it may guide

investigation into the right channel at the outset. But even with such

favourable odds there is no need for diagnosis to rely entirely on chance if the

circumstances of the failure are properly taken into account.

So the first questions to be answered are: (a) Did the power fail suddenly

without any warning? (b) Did the engine begin to misfire before stopping? (c)

was failure preceded by a temporary disinclination to pull, and did the engine

show any sign of reviving before it finally faded out? (d) After stopping

did-the engine restart but only run for a few seconds? (e) Was the failure

accompanied by any unusual noise or smell? From the answers to these questions

much can be inferred! Failure as in A is in all likelihood due to the ignition;

B arises mainly from ignition faults, but may be the result of weakening

mixture; C is almost surely fuel failure; D points to some restriction in the

petrol supply but not a complete stoppage, With E we will deal later.

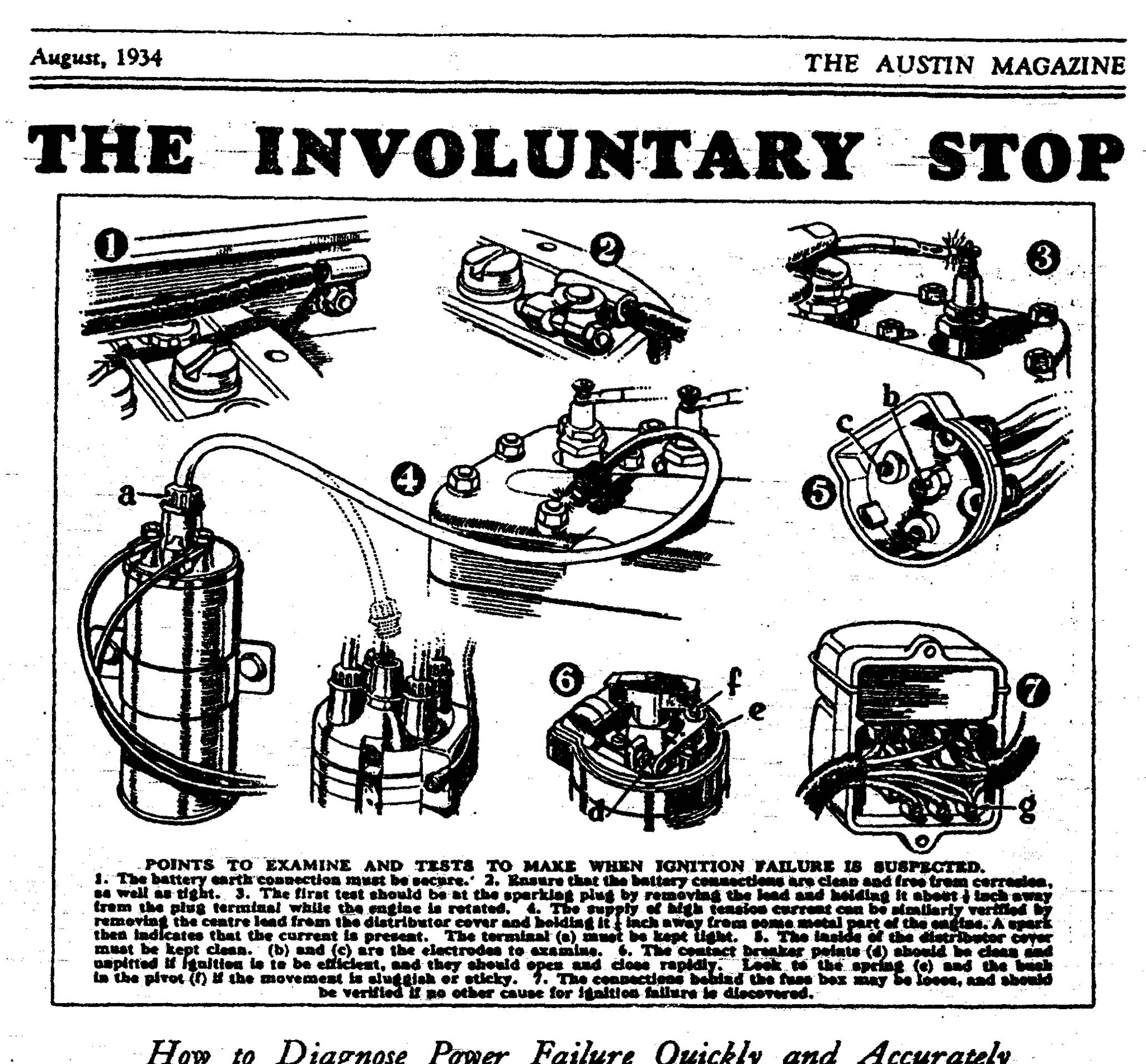

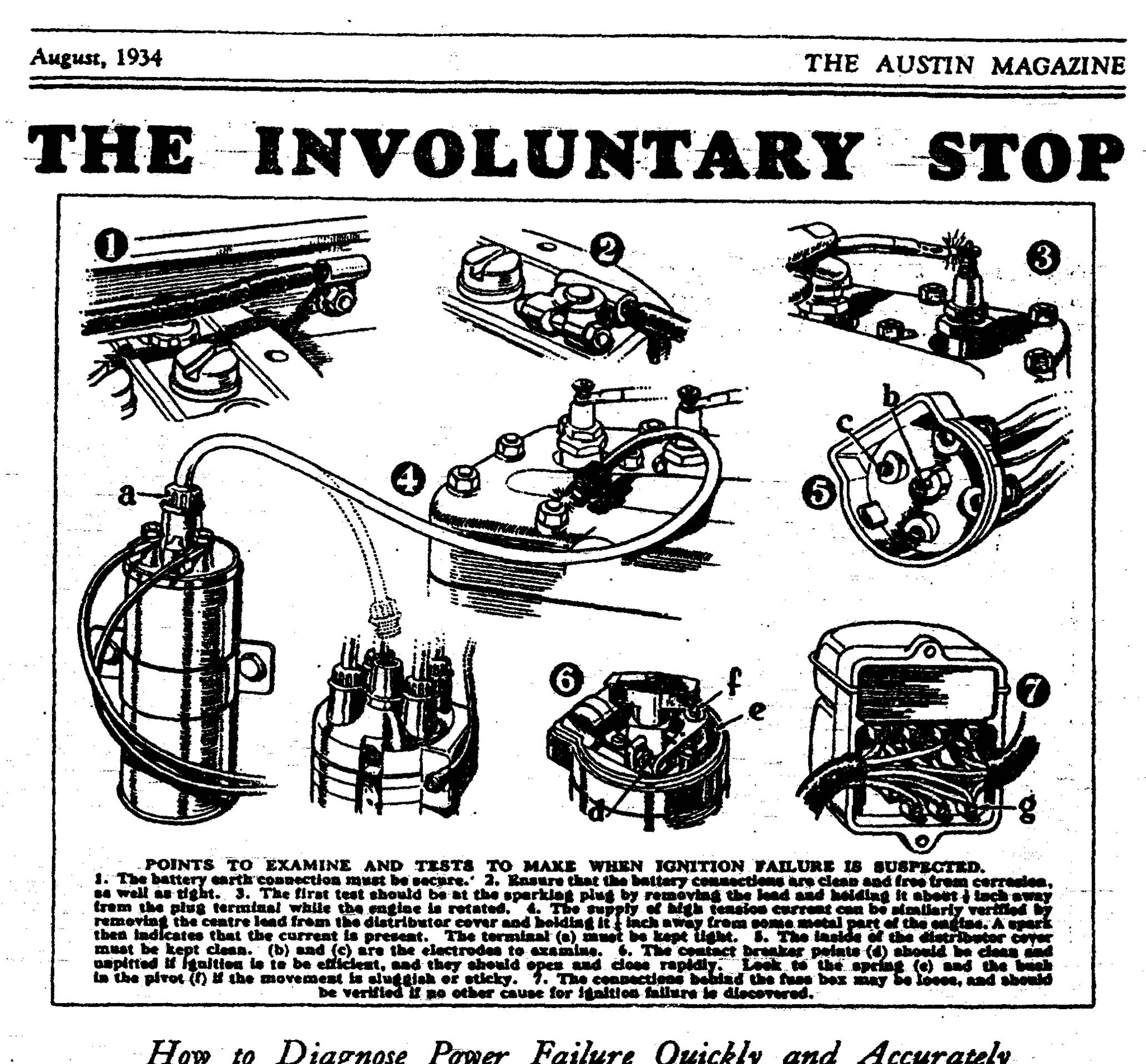

Bearing the above facts in mind, it is clearly wise to check up first of all

the two most obvious points in both systems, i.e. the amount of petrol in the

tank, and the supply of ignition current from the battery, as indicated by the

fuel gauge and the ignition warning light respectively. If these points seem in

order, but the symptoms indicate ignition trouble, remove a sparking plug lead

and hold it close to its terminal on the plug whilst the engine is turned over.

If a spark results, ignition trouble can be dismissed subject to one

reservation. This is necessary because a spark may occur at low starting speeds

and yet fail at running speeds due to a condenser or contact breaker fault, or

some breakdown of the insulation. There is little object in testing more than

one plug terminal as it is unlikely that failure would simultaneously occur in

all four high tension leads. Of course, if their condition is uniformly

desperate, and they are all either badly perished or oil sodden, they will be

suspected at the outset. When this test produces no spark, proceed to the high

tension lead that runs between the coil and the distributor. First see that its

terminals are secure, then disconnect at the distributor end and hold the bare

cable about ˝ in. from the engine casting, or any other metal part through which

the current can flow to earth. When the engine is turned over a healthy spark

should then result. If this spark occurs the next step is to examine the carbon

brush in the distributor over the rotating arm on which it bears, the segments

to which this arm distributes the current, and the terminals of the high tension

leads to the plugs. Any defect causing a breakdown should be readily observable

and dust or oil inside or outside the cover are in themselves quite sufficient

to upset ignition. If no fault is immediately obvious, turn to the fuel system.

But in the event of this test with the coil to distributor lead proving

negative, no spark being forthcoming, the coil or contact breaker can be

suspected.

IGNITION FAULTS

Examination of the contact breaker points to see whether they move freely and

to ensure that they have not worn or burned badly is the first step. Points that

have burned and reveal a milky-white corrosion, indicate condenser trouble for

which the remedy is a new component. Badly-pitted or worn points are liable to

cause erratic running at least. But the spring which closes the contact breaker

points may be the guilty member, having weakened or broken. Further, ensure that

the distributor spindle rotates properly. Lack of lubricant has been known to

result in this spindle seizing to shear the teeth of its driving gear. Turning

to the coil, practically the only thing the owner can verify here is the

security of the terminals, especially that for the high tension cable, which

should make good contact in its socket. The remedy for coil failure is a new

coil, but do not too hastily assume this to be the fault before exhausting all

other possibilities, including the ignition connections in the junction box

behind the fuses. If, on the first investigation, the warning light does not

respond to the ignition switch and the ammeter records no discharge, the very

first step is for the battery to be examined to verify whether a terminal is

adrift or any corrosion has set in to prevent the flow of current. The earth

connection from the battery to the frame should not be overlooked. Of course,

the battery may be discharged, but the driver will have many indications of this

before engine failure supervenes. These, then, are the main coil ignition

defects for which to look, but remember that the cause of failure is often very

simple, so check over all connections, leads, and terminals and look for oil and

dirt where their presence may be harmful. It is a good plan to keep a roll of

insulating tape in the car, and some careful motorists carry with them wherever

they go a spare coil and a replacement contact breaker spring "just in case."

With magneto ignition the same advice applies in general in respect of the

contact breaker, distributor and leads. A point to remember, however, is that

the ignition is switched off by earthing the contact breaker. Consequently, if

the insulation of the cable connecting the switch to the contact breaker cover

becomes faulty and allows the current to escape to earth, the ignition may be

restored by disconnecting this cable from the contact breaker cover. Another

vulnerable point on the magneto is the slip-ring under the casing at the drive

end of the unit. The high tension current is picked up at this point and a dirty

or pitted slip-ring or a faulty brush in contact with it, will sometimes cause

ignition failure. The carbon brush behind the contact breaker is yet another

point to examine when no spark, is forthcoming.

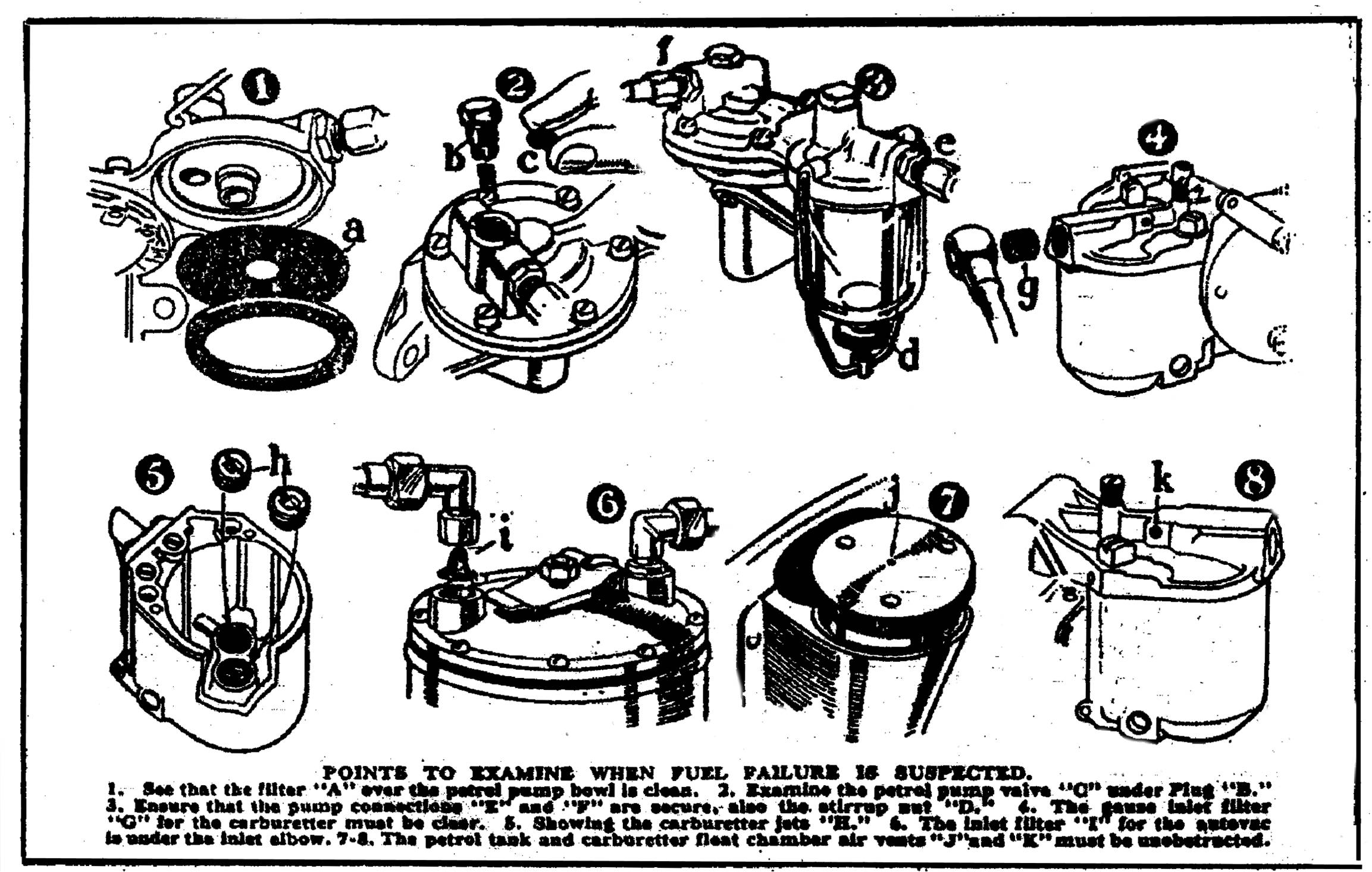

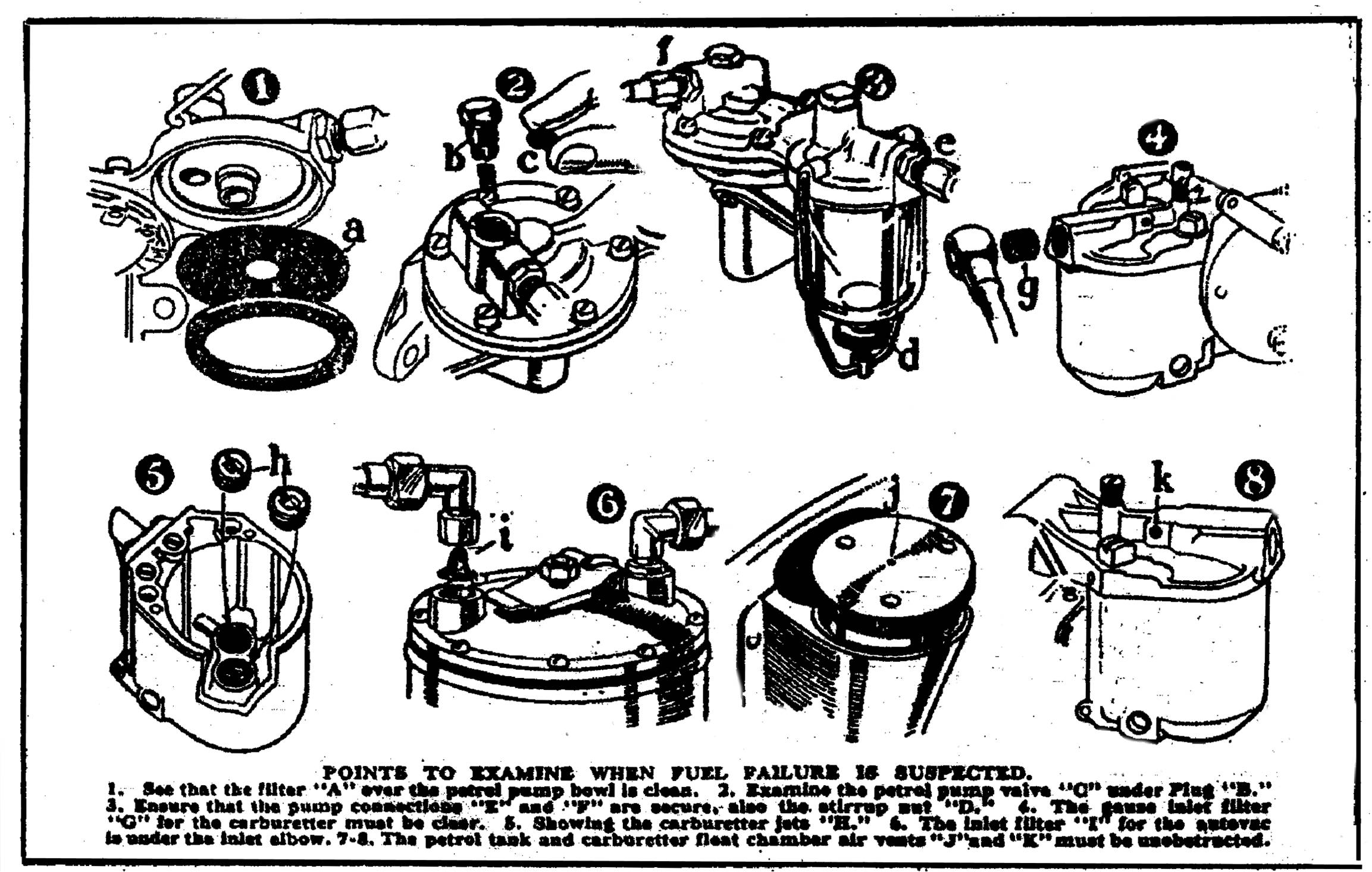

FUEL PROBLEMS

In the fuel system, attention can be first directed to the carburettor when

tracing the cause of engine failure, although a glance at the filter bowl (if

fitted) under the petrol pump may show without more ado where the trouble lies.

Apart from this, the first procedure should be to remove the float chamber cover

or dismount the chamber (according to type), to see how much petrol is within.

Absence of petrol should direct investi�gations back towards the source of

supply. A normal quantity of petrol should direct it forward. Dealing with the

latter first, the jets should be removed and examined for stoppages -the main

jet in particular. An obstruction can be blown clear against the direction of

petrol flow. But before emptying the petrol from the float chamber, look for

globules of water at the bottom. Some of the most puzzling engine failure

problems have resulted from water in the fuel. Then the throttle and carburettor

controls might be inspected if the trouble is still obscure. On most

carburettors, if the control becomes disconnected the throttle closes. When the

float chamber is found to be empty, or comparatively so, the first step in

tracing back�ward towards the source of supply is to dis�connect the inlet union

and look for any stoppage in the filter gauze. Then, if all is in order, the

petrol pump can be considered. Are all its unions secure as well as the top

cover (or glass filter bowl, according to type)? Air leaks at any of these

points will affect the delivery of the fuel. The filter in the petrol pump

located over the filter bowl or under the cover (whichever type of pump is

involved) is a point to examine, as also are the small valve plates (accessible

on removing their cover plugs.) The latter, if warped, or for any other reason

unable to seat properly, will render the pump ineffective. With autovac fuel

feed there is a vent cap in the top of the unit, and a small conical filter

under the inlet union to be examined if the fuel is not reaching the

carburettor. Naturally, the suction connection from the induction manifold must

have its unions at each end secure. Other points in the petrol system which can

possibly be suspected are the union on the petrol pipe at its tank end, which

must, of course, be tight, the air vent hole above the float chamber of the

carburettor, and (especially on gravity feed models with a dashboard tank) the

vent hole in screw-type filler caps. These vents must be kept clear. While we

have briefly surveyed the more likely causes of failure, it must be realised

that there are many other possibilities to consider in a complex mechanism such

as a car engine. Thus a defective cylinder-head gasket which allows water to

leak into the cylinders can quite easily bring about a stoppage. Loss of cooling

water, as discovered on examining the level in the radiator, water dripping from

the exhaust (except the usual condensation when starting), and the presence of

water in the combustion chambers as found on removal of a plug, will readily

point to this trouble. A timing chain failure, although a rare occurrence, is

also a possibility. It will usually be accompanied by noise and can be verified

by removing the valve cover(s) and watching the valves while the engine is

turned. Then, as already mentioned, some stoppages occur following the advent of

an unusual noise; sometimes the owner is forced to stop to avoid the engine or

some other unit suffering. In these circumstances the noise itself is the

essential clue, and if a vital part has failed, a proper repair is the only

cure. Engine seizures are nowadays few and far between apart from those arising

from sheer neglect or abuse. The remedy in case of seizure is to wait for the

engine to cool and hope for the best while application of lubricant to the

suspected parts will naturally help. Yet in nine cases out of ten engine

failure, whatever form it takes, will be found to arise, not from any inherent

defect in the unit itself or in any of its auxiliaries, but from some atten�tion

that has been neglected, or some abuse of the mechanism. That is a fact which

the careless motorist should take to heart.

IN these days of dependable motoring, engine failure or other derangement

enforcing a stop is comparatively rare. Tens of thousands of miles can normally

be covered without an involuntary halt. Yet perhaps it is this very immunity

which sometimes leaves the motorist unprepared when the unexpected happens, and

the car comes to rest as, in vulgar parlance, the engine "conks out." When the

engine fails, tracing the causes and effecting a remedy calls for the

application of practical experience. Close reasoning, and not a little ingenuity

may be needed, for "troubleshooting" (as our American friends call it) requires

an alert mind to comprehend quickly the many possibilities that arise. But as a

start these can, with certain exceptions, be broadly divided into fuel or

ignition defects, and, according to breakdown statistics, the odds in favour of

the latter are ten to one. That is a fact worth remembering for it may guide

investigation into the right channel at the outset. But even with such

favourable odds there is no need for diagnosis to rely entirely on chance if the

circumstances of the failure are properly taken into account.

IN these days of dependable motoring, engine failure or other derangement

enforcing a stop is comparatively rare. Tens of thousands of miles can normally

be covered without an involuntary halt. Yet perhaps it is this very immunity

which sometimes leaves the motorist unprepared when the unexpected happens, and

the car comes to rest as, in vulgar parlance, the engine "conks out." When the

engine fails, tracing the causes and effecting a remedy calls for the

application of practical experience. Close reasoning, and not a little ingenuity

may be needed, for "troubleshooting" (as our American friends call it) requires

an alert mind to comprehend quickly the many possibilities that arise. But as a

start these can, with certain exceptions, be broadly divided into fuel or

ignition defects, and, according to breakdown statistics, the odds in favour of

the latter are ten to one. That is a fact worth remembering for it may guide

investigation into the right channel at the outset. But even with such

favourable odds there is no need for diagnosis to rely entirely on chance if the

circumstances of the failure are properly taken into account.