THE AUSTIN 7 THREE SPEED GEARBOX

(Adapted

from an article by Mike Phelan which appeared in the Pre War A7 Club Newsletter

for Sep 93)

There

have been many texts written on the overhaul of the Austin Seven engine,

brakes, steering and most other bits of our favourite car - but the gearbox has

been somewhat left alone. There is, however, good reason for this - it gives

little troub le and continues to give good service, even when absolutely worn

out! Gearboxes rarely fail catastrophically. Nowadays, the supply of good

secondhand gearboxes is slowly diminishing, so we are having to rebuild them,

maybe using parts from several units.

le and continues to give good service, even when absolutely worn

out! Gearboxes rarely fail catastrophically. Nowadays, the supply of good

secondhand gearboxes is slowly diminishing, so we are having to rebuild them,

maybe using parts from several units.

Most

of us will strip an engine with few qualms but steer clear of gearboxes and

differentials, which have fewer parts than an engine! This is perhaps because

of a lack of understanding of how the gearbox works so I make no apologies for

giving a brief elementary description of this: after all, we have a steady

influx of new members to cater for. I crave patience from our more experienced

members.

General Design and Operation: Design

The

unit is a fairly conventional 3-speed sliding mesh gearbox with either a ball

change or a gate change on earlier units. The gate change boxes have a ball

joint at the base of the gear lever, the function of the gate being to restrict

movement and to provide a reverse stop. Ball races are used on the four main

bearings, bronze bushes elsewhere.

Principle of Operation

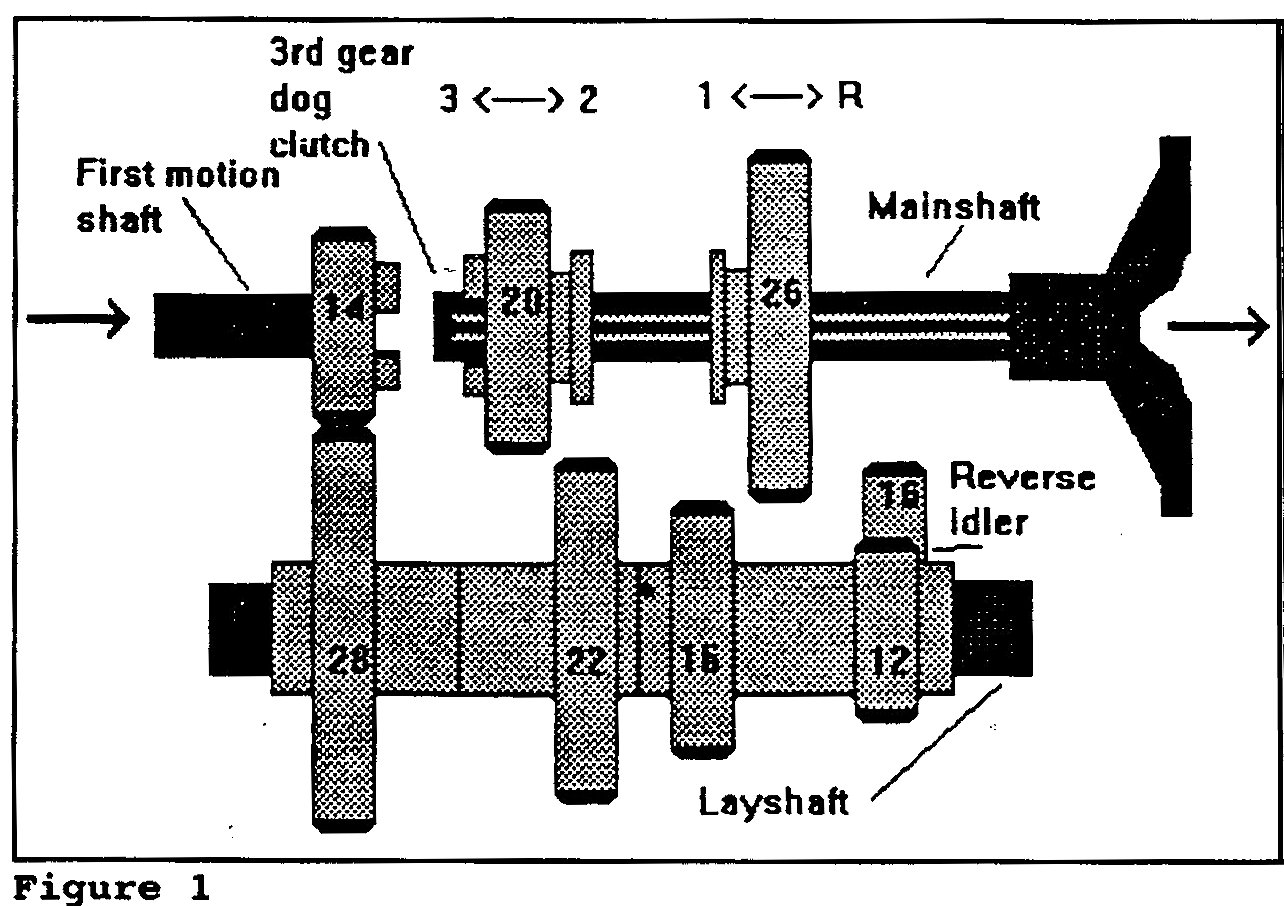

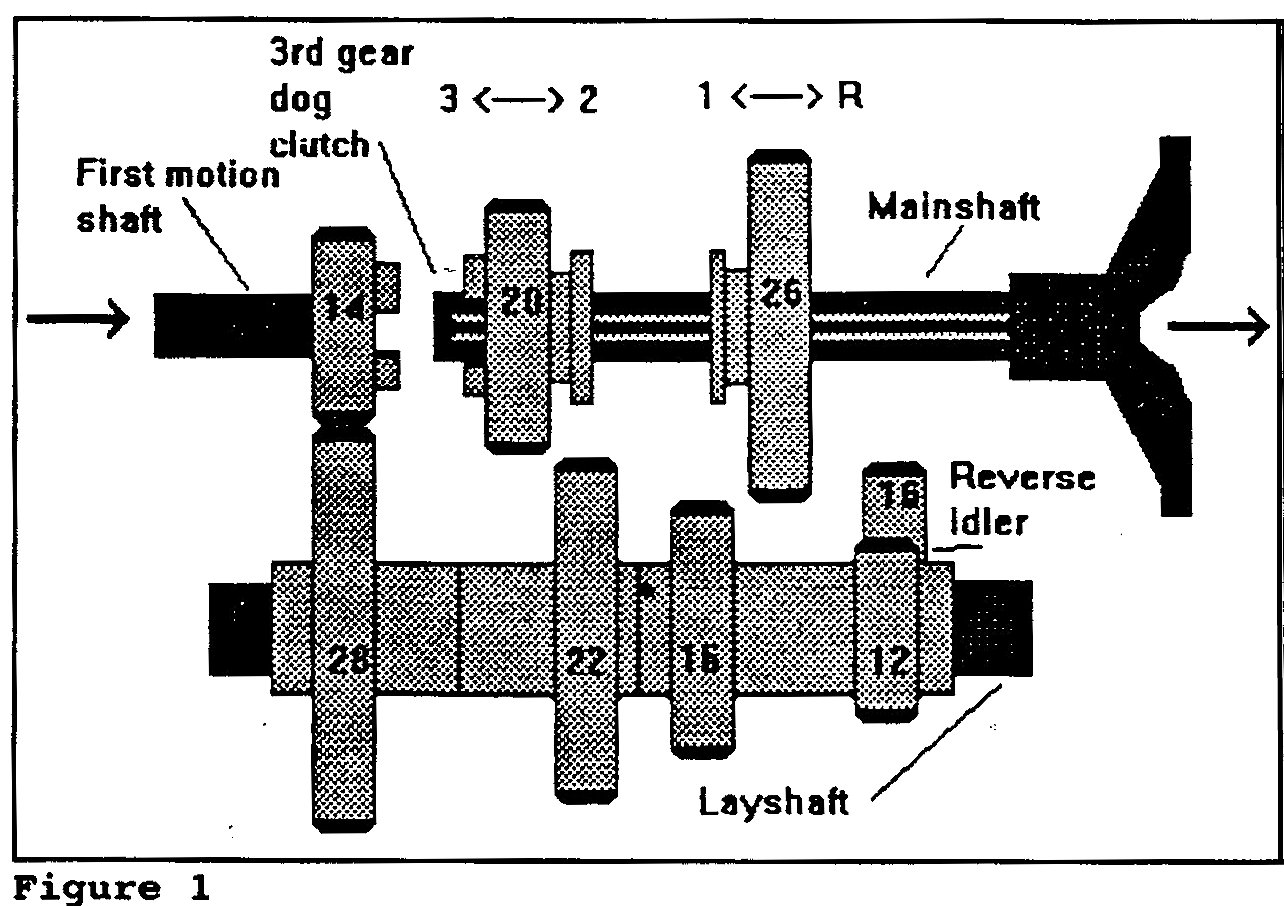

The

gearbox, like most, has four shafts, viz:

1.

A first motion or input shaft that

is driven by the engine via the clutch. It has an integral constant mesh pinion

to the layshaft (see below).

2.

A mainshaft that delivers output to

the propeller shaft and is locked to the first motion shaft to give top gear,

which therefore has a 1:1 ratio. The mainshaft is splined and carries two

sliding gears.

3.

A layshaft, situated at the bottom

of the gearbox, permanently driven by the first motion shaft. It, in turn,

drives the mainshaft through one of the sliding gears, except when top gear is

selected.

4.

A reverse idler to change the

direction of rotation. This meshes permanently with the reverse pinion on the

layshaft.

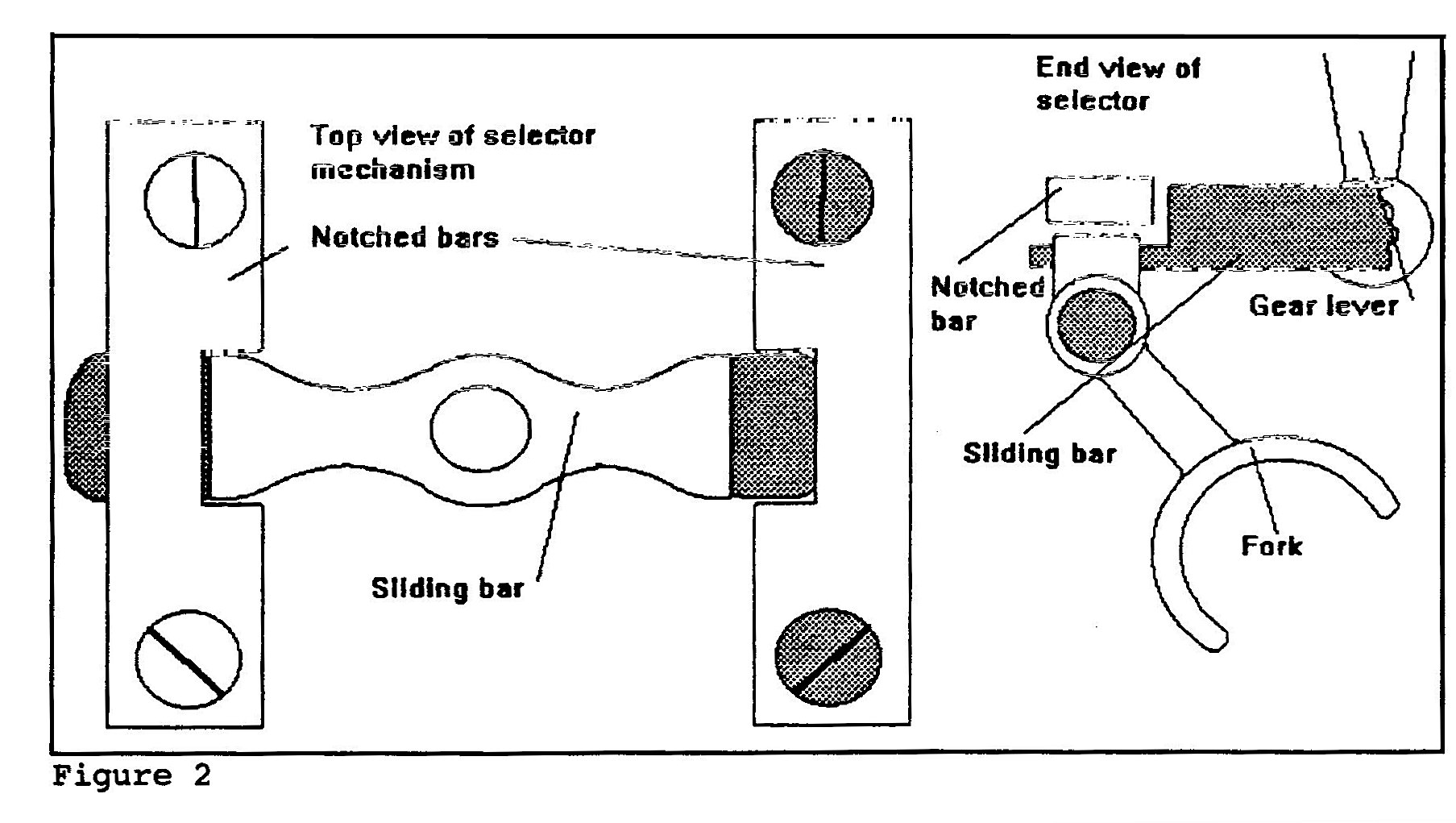

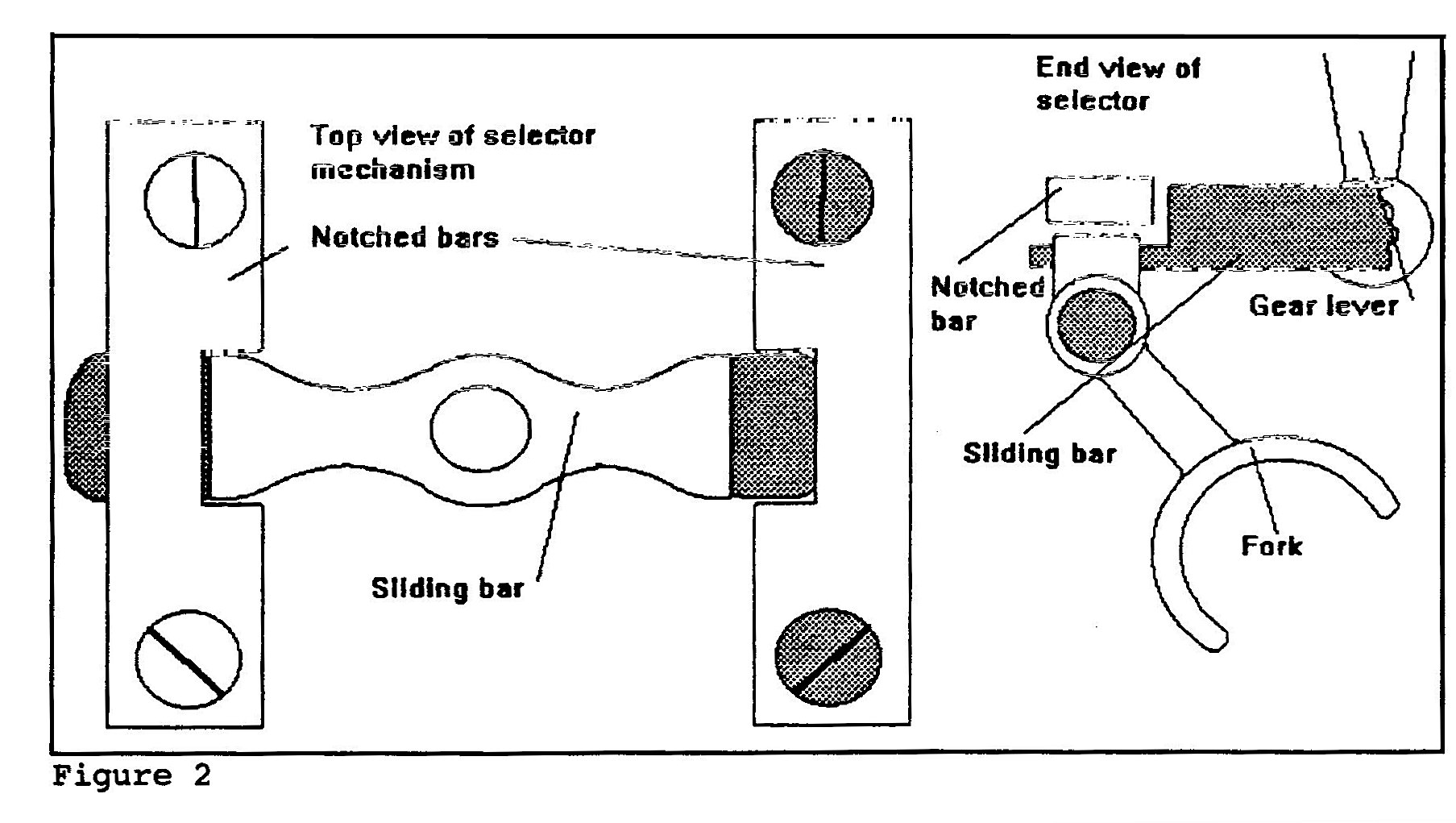

The two sliding gears on the mainshaft are moved by selector

forks, and the Seven uses a rather unconventional method of moving these. On

most cars, they are moved by the end of the gear lever. On the Seven, they are

moved by a sliding bar with a hole into which the gear lever end fits. This

gives a slight leverage and a shorter travel on the gear lever. The sliding bar

ends are stepped and fit under two notched bars screwed into the gearbox case

(see Fig 2)  This provides a very necessary part of any selector mechanism, an

interlock to prevent more than one selector fork moving at a time. This, if it

were to happen would lock the box solidly and probably cause sever damage to

the car, and possibly its occupants!

This provides a very necessary part of any selector mechanism, an

interlock to prevent more than one selector fork moving at a time. This, if it

were to happen would lock the box solidly and probably cause sever damage to

the car, and possibly its occupants!

The

interlock operates by having steps on the sliding bar ends that prevent the bar

from moving the forks until it is at the extreme left or right of its travel.

In these positions, one of the stepped ends fits into the notched bar acting as a fulcrum, the other end being clear and free to move. On gate change boxes,

the gate also acts as an interlock.

For

first and reverse gears, the sliding

first gear on the mainshaft is moved into engagement with either the first gear

pinion on the layshaft, or the reverse idler.

For

second gear, the sliding second gear

engages the layshaft second gear pinion.

For

top gear, the face of the sliding

second gear carries four dogs that engage similar dogs on the face of the

constant mesh pinion (see Fig 1), thus locking the mainshaft to the first

motion shaft. The gearbox is now effectively 'out of circuit'.

Gear Changing

When

we are in, say, first gear, doing 15 mph, the engine is rotating at some 3000

rpm and the layshaft at half this speed. If we were doing the same speed in

second gear, the engine would be running much slower and the layshaft rotating

at only 865 rpm. So, therefore, to change upwards silently, we must slow the

layshaft down to somewhere near this speed whilst in neutral so that the two

second gear pinions are rotating in step. As soon as we go from first to

neutral, this starts to happen but the rotating mass of the layshaft, first

motion shaft and clutch driven plate has considerable inertia and would take

some time to reach the required speed. The engine slows down much more rapidly

than this so we briefly release the clutch whilst in neutral to allow the

engine to slow the spinning layshaft.

It

is not quite so simple in practice as there are some variable such as oil

temperature and grade to be taken into account. Cold gearbox oil slows the

shafts down almost immediately but on a hot summer day, upward changes can take

several seconds. Also, if you are on an upward gradient„ the car loses road

speed while you are changing gear so the layshaft slows down even more.

Conversely, road speed increases during a change on a downhill stretch, so that

upward changes can be performed more quickly.

To

change down, the opposite rules apply. The layshaft must be speeded up, so we

rev the engine as we release the clutch in neutral, or just hold the throttle

open moderately. More revs if going down hill, less if going up as the road

speed helps to match the gear speeds.

Gearbox Data

Much

of the data published on gear ratios etc are slightly incorrect. This is rather

surprising as calculating gear ratios simply involves counting the teeth and

performing some very simple arithmetic. Many of the errors have been

perpetuated; as is often the case. William's book on Specials [Ed see A7

Library, Jan 93] gives the ratios for the three speed box to 2 decimal places,

but there are slight errors, even allowing for he axle ratio being stated as

4.9 rather than 4.89 (44/9). I am not trying to be pedantic here, but I think

if figures are stated to an accuracy of 2 decimal places, then they should be

reasonably accurate.

|

Gear

|

Gearbox

|

Overall

|

|

Reverse

|

4.33

|

28/14 X 26/12

|

21.19

|

|

1st

|

3.25

|

28/14 X 26/16

|

15.89

|

|

2nd

|

1.82

|

28/14 X 20/22

|

8.89

|

|

3rd

|

1.00

|

(Direct)

|

4.89

|

As

for the rear axle ratio, we always say 5.25, 5.125 and so on. So why not 4.89

instead of 4.9? The ratios given in 750 MC 'Co

mpanion' are correct. These data

assume a 4.89:1 rear axle ration and a tyre size of 3.50 x 19. This gives 778

turns per mile of the rear wheels. Incidentally, ratios for fourspeed boxes

tend to be mis-quoted sometimes. The early 32/33 crash box has slightly

different (wider) ratios from the later synchro boxes.

|

Engine RPM at various Road Speeds

|

|

MPH

|

1st Gear

|

2nd Gear

|

3rd Gear

|

|

10

|

2060

|

1153

|

|

|

15

|

3090

|

1729

|

|

|

20

|

|

2305

|

1268

|

|

25

|

|

2881

|

1585

|

|

30

|

|

3458

|

1902

|

|

35

|

|

4034

|

2219

|

|

40

|

|

|

2536

|

|

45

|

|

|

2853

|

|

50

|

|

|

3170

|

Close Ratio Conversions

Users

of the 3 speed box will know only to well the wide gap between 1st gear and

2nd. Conversions to reduce this gap have been available for many years. To

convert to close ratio, it is necessary to make a new first motion shaft and

lay shaft constant mesh gear with a reduction ratio less than the standard 2:1

(28/14). If the same pitch of teeth is used, then the total of the teeth on the

two gears must be 421, (the answer to life, the universe and

everything). Say you made new gears of 16 and 26 teeth; this would give you a

first gear of 12.91:1 and a second gear of 7.22:1. As making a first motion

shaft would be extremely expensive, most conversions just machine off the old

gear and press fit a new one.

The sum of the tooth counts for

each of the three pairs of gears must be the same, if the teeth are to have

identical pitch. The three gears used for reverse do not obey this rule as the

reverse idler can be positioned to provide the correct meshing depth.

PROBLEMS

These

gearboxes, as was mentioned last month, are fairly trouble free. Unlike the

later synchromesh boxes, the mainshaft gears do not rotate on the shaft so

there are no bushes to wear. The main problem is noise, due to the rather

course straight-cut gears.

Remember

that even when new, there would have been considerable whine in the indirect

gears. This can be alleviated by using a thicker oil than the recommended

engine oil. I use SAE 50 engine oil in mine, although thicker oils than this

(such as SAE 140) can be used with no apparent damage. If you use your car in

winter, though, using very thick gearbox oil will make changing upward

difficult, for reason mentioned earlier. Avoid oils with sulphur-based

additives, designated 'EP' (extreme pressure) although not all EP oils contain

sulphur. Sulphur

additives will attack any bronze~selector forks and bearings), making your oil

look like gold paint!

Very

severe damage or wear will result in jumping out of gear although this can also

be caused by seized or broken selector springs. The gearbox tops, both types,

wear rather badly as the steel gear lever ball runs directly in the alloy

casting . The ball change top has the lever retained by a threaded ring and the

hole in the top sometimes wears so badly that the lever comes out! The slot in

the ball also wears, but this can be built up by welding. There is definitely a

need for someone to start casting tops of both sorts, or is someone already

doing this?

REMOVAL

Unfortunately,

on all cars with three-speed boxes, the engine will have to be removed, either

with or without the gearbox first. On earlier cars without a dummy spline, it

is easier to lift out the engine separately, then remove the gearbox. If you

remove both together, it will be necessary to remove the cotter from the clutch

pedal to allow the later to rotate clear of the floor, having first removed the

pedal top.

DISMANTLING

Before

doing anything wash the gearbox externally then drain the oil. Collect some old

containers to put small parts in. You will need four small boxes for the

selector shims and a marked piece of wood with four nails for the other shims.

Mark the boxes as shown in the table below:

|

Boxes

|

Board

|

|

1 RF

|

1st/reverse front

|

FM

|

First Motion shaft

|

|

1 RR

|

1st/reverse rear

|

MS

|

Mainshaft .

|

|

23 F

|

2nd/3rd front

|

LSF

|

Layshaft Front

|

|

23 R

|

2nd/3rd rear

|

LSR

|

Layshaft Rear

|

The

first and sometimes the most difficult part to remove is the clutch shaft. This

is retained by two taper pins that must be driven out. If you hit them with a

hammer you will only succeed in flattening them. Use a punch or if that fails,

drill them out. Be very careful of the brittle gearbox casing. Remove the

clutch shaft and withdrawal levers, noting the position of the washers. Then

remove the gearbox top and front covers and put to one side.

Warm

the gearbox casing with a fan heater, or use a hot-air gun but be very careful.

This makes removing the bearings much easier. When taking the front cover off,

turn the box front uppermost, so that the our sets of shims do not fall out.

These must be put in the marked containers unless you want to start from

scratch when re-assembling. Granted, we are assuming that the box has not been

stripped before - true in a surprising number of cases. Some shims may be stuck

to the cover. There are large shims on the two ball races and small ones about

the size of a 5p piece, on the selector rails. The latter may remain in the end

of the bore. The layshaft rear bearing has a pressed steel disk on top of the

'N shims. This is a distance piece and care must be taken during reassembly not

to replace it in the front bearing in error. Take out the four screws holding

the notch bars; you may need an impact driver for this. The selector bars will

then be free and can be removed.

Take

out the speedo drive bush and pinion if present. Remove the rear cover,

complete with mainshaft which will slide out. Again beware of shims - four lots

again!

The

selectors can be removed, but carefully! Push each rail rearwards and continue

until it is flush with the end of the selector fork. Then put your thumb and

finger over the fork end and the small hole in the top and pull the rail out.

The steel ball will now be loose inside the fork and can be retrieved, possibly

with aid of a magnet. Repeat the process with the other fork. As the rods are

identical, mark then so they can go back in the same positions. The springs can

be pulled out with a wire hook.

The

two sliding gears can be taken out now and a brass drift used to remove the

first motion shaft. The layshaft is a little more difficult. The gear is in

three parts, retained by two keys which will not pass through the bearings. To

remove, tap the shaft rearwards until the rear bearing is free of the case.

Turn the box on its front and place two pieces of brass or alloy strip between

the bearing and case. Drift the layshaft back into the box and remove the

bearing. Continue to drift the shaft out forwards, retrieving the two keys. The

longer one is invariably broken in two pieces. The reverse idler shaft can now

also be drifted out.

Remove

the circlip from the mainshaft, remove the shaft, bearing and seal plus the

speedo drive worm if fitted.

Examination

Wash

all parts off in a degreasing fluid or paraffin followed by petrol. Examine

the gear teeth for corrosion or pitting that has penetrated the case hardening.

The engaging edges of the gears should be chamfered, but look for damage and

chipping which will cause noise and jumping out of gear.

The

layshaft is frequently bent but replacements are inexpensive. The keys will

need replacing, too, but the long one probably breaks in the first 1000 miles!

Bearings do not wear much, replacing them may increase noise by changing the

depth of engagement. Give the four ball races a final wash in clean petrol and

check them for wear and roughness. If you are going to re-use them, oil them

with engine oil and wrap in paper to keep the dust out until you re-install

them. Any felt seals will need replacing with new ones soaked in molten tallow.

The spigot bearing in the First Motion Shaft sometimes wears slightly.

The

selector forks tend to wear where the sliding bar engages them. Building these

up with bronze will improve the change considerably. The notched bars can also

wear, and can be built up with weld. Do not, however, give the final finish

until the box is being re-assembled, as they need to be fitted exactly.

When

replacing gears with those from another box, replace them in pairs if possible,

or you may end up with a noisy box. Remember to include the reverse idler, and

that it rotates all the time that the clutch is engaged. A severely worn idler

can produce a surprising amount of noise, even in neutral. Ensure that all the

ball races are tight, on the shaft and in the case. Clear out the spring holes

in the selector forks with a drill or reamer, as they tend to burr. Throw the

old selector springs away.

Reassembly with Original Shims

If

you are not replacing all the shims in their original positions, refer to the

next section for details of how to set up the gearbox by re-shimming and this

section for detailed assembly instructions.

The

first thing to do is to place all the layshaft gears in the bottom of the box, then

to feed the layshaft from the front, not forgetting to fit all the keys, which

can be stuck in place with grease. The long key goes to the front. It sometimes

helps if the first 1/8" or so of the keyways in the gears is chamfered

with a needle file. This avoids the sharp edge planing a shaving off the key.

When the layshaft is fully in position, fit both bearings after warming the

casing up again. Use a tubular drift, with a block of soft metal supporting the

other end of the shaft. An extra pair of hands is useful here. Tap the rear

bearing in the furthest, to allow room for the distance piece.

Replace

the first-motion shaft and bearing, and temporarily fit the mainshaft into the

two sliding gears. Place both selector forks in position, noting the markings

that you made on dismantling. The selector shafts will then need fitting, and

this is a slightly awkward job , due to the fact that the springs need

compressing.

, due to the fact that the springs need

compressing.

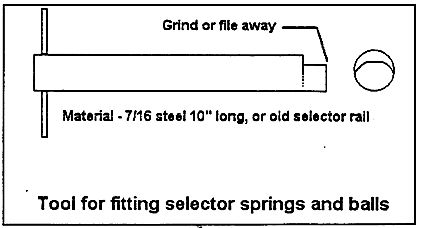

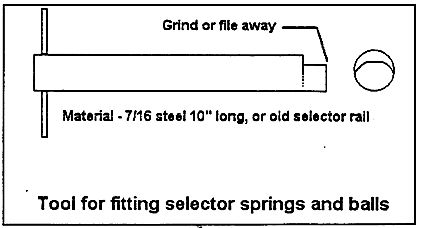

I

find that the best way to do this is to make up a special tool consisting of a

piece of bar as in the drawing opposite. To

use it, put the spring and ball, heavily greased, into position and insert the

tool into the front of the fork bore until the end just covers the hole. Turn

the tool a quarter turn; this will compress the spring. Fit

the shafts into position as follows. The 2"d/3' shaft is the one with the

grooves unequally spaced. Look for the wear

on the grooves caused by the ball and fit the shaft so this wear is at the top.

Push the shaft in till it

meets the tool, then give a tap with a hide mallet or soft drift whilst holding

the tool. Once the shaft has

gone in past the hole, remove the tool and tap the shaft home until 1/8"

or so short of the front face

of the gearbox.

Turn

the gearbox front uppermost and fit all the original shims in position, then

the gasket and the front cover. Turn it over, remove the mainshaft and assemble

the latter with seal, bearing and speedo worm to the rear cover. Refit the

circlip and close with a vice. Tap the selector rails forward and do the same

to the layshaft bearing. This ensures that there is no looseness in the shims

at the front. Refit the rear shims, the distance piece on the layshaft and the

gasket. Refit the rear cover and tighten the bolts.

Reassembly with New Shims

In

an ideal world, if we replace all the shims in the positions that they came

from, all will be well. Unfortunately, if the box has been stripped before, or

any parts swapped, it will be necessary to re-shim the box. To do this, you

really need a selection of shims as well as those fitted originally, but it may

be possible to just use the original shims. The process must be carried out in

the correct order, as most of the shims affect more than one thing. Like any

similar process, the aim is to finish with the adjustment that only affects one

item.

What

are we aiming for? Full

engagement of the reverse idler and the layshaft reverse pinion. Full

engagement of 1S`, reverse and 2"d gears, and equal clearance in neutral.

Correct engagement of 3rd gear dog clutch.

Full engagement of the constant mesh

pair.

Procedure:

The box is assembled as in the previous section, except that the covers are

left off the mainshaft and the first motion shaft, and the balls and springs

are left out of the selectors. This is so that the gears can be engaged without

disturbing the positions of the selector rails. Ensure that the layshaft is

likewise pressed hard against the ends of the gear cluster and that the first

motion shaft bearing is likewise fully home. Check that the selector rails are

a firm fit in the gearbox case and cannot move easily.

1. Put the 1st/reverse selector in the reverse gear position

(back) and pop the ball, with some grease on it, into the top hole to

centralise it.

2. Tap the selector rail either way, holding the ball in place,

until the sliding gear and reverse idler appear to be fully engaged.

3. Tap the layshaft bearing (not the shaft) with a hollow drift

until the reverse pinion on the layshaft engages fully with the idler.

4. Return the selector to neutral and check that the clearances

either side of the 1st/reverse sliding gear are equal and at least 0.1".

If it is too near the layshaft first gear, move the layshaft; if to near the

reverse idler, move the selector rail.

5. Repeat adjustments 2, 3, and 4 until correct.

6. Place the 2"d/3' selector in neutral and stick a ball

in the top hole with grease, as before.

7. Tap the first motion shaft bearing outer race, not the

shaft, until the constant mesh gears engage correctly and there is at least

0.1" clearance between the halves of the dog clutch.

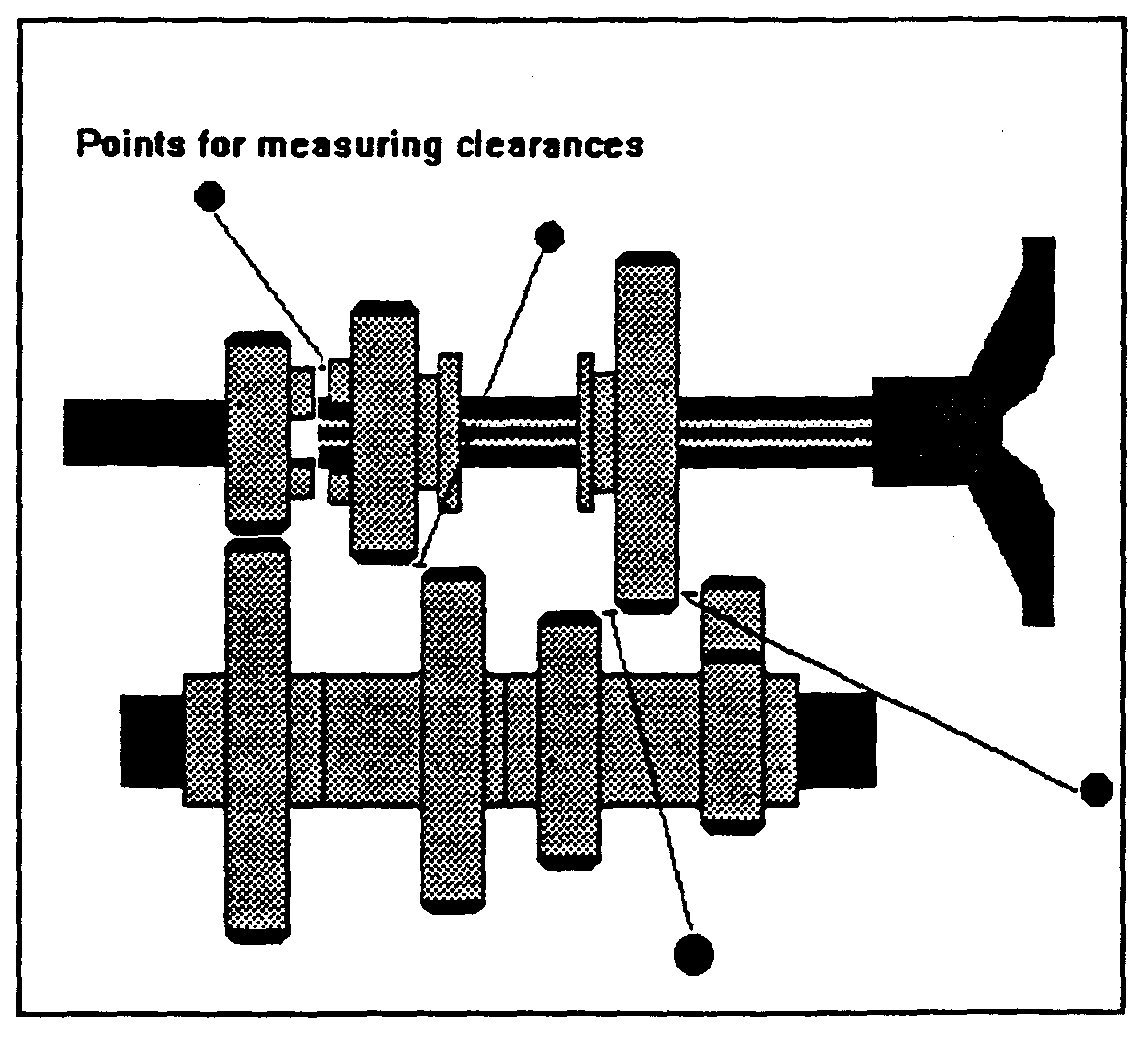

8. Tap the selector rail to give 0.1" clearance between

the sliding second gear and the corresponding layshaft pinion.

9. Repeat 6, 7 and 8 until correct.

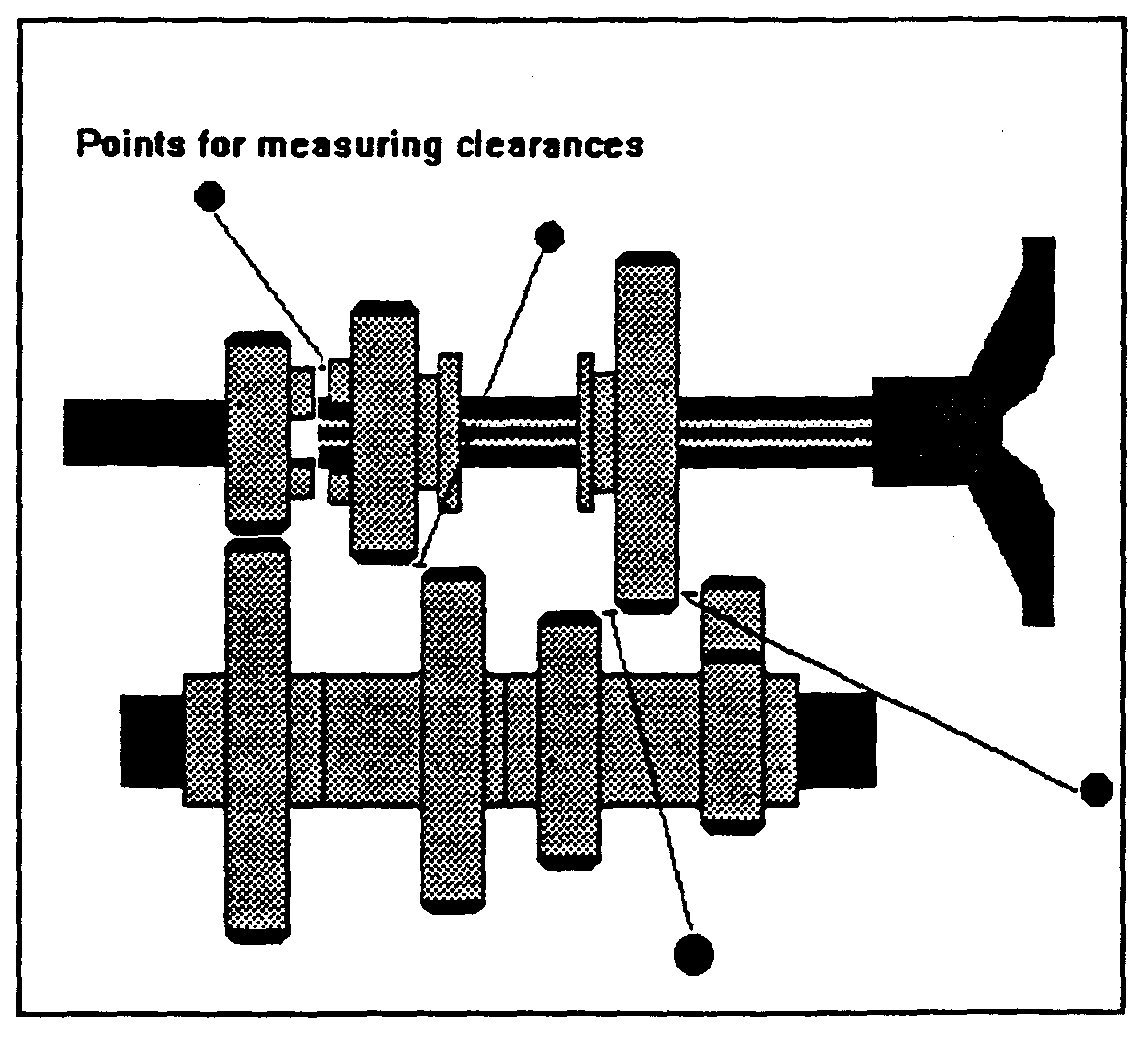

10. With a straight edge and feeler gauges, measure the depth of

the two front ball races below the gearbox face and write these down. Do the

same with selector rails (front only).

11. Remove the selector rails and refit the

balls and springs (see previous section).

12. Fit a new seal to the front cover and fit

the washer that retains it.

13. Select shims to the thickness that you noted, plus the

thickness of the front cover gasket, and support the box front upwards. Fit the

four sets of shims and the gasket, coated in goop if you wish, then bolt down

carefully.

14. Tap the mainshaft gently until it will move no further. Also

tap the layshaft rear bearing and the selector rails, the latter only gently.

15. Measure the depths as you did the front.

Add the thickness of the gasket to the figures and from the mainshaft bearing

depth, deduct 0,020" for spigot bearing end float. From the layshaft

figure, deduct the thickness of the distance piece.

Remove

the mainshaft and bearing, refit the cover with a new seal and washer. Squeeze

the circlip into its groove in a vice - it is very soft, fit the shims and

gasket and replace the cover. This completes the shimming process.

Reassembling the Selector Bars

Place

both selector forks in neutral, then refit the sliding bar, well greased. The

notched bars should then fit so that the sliding bar slides freely, with equal

clearance either side of the square portions where they enter the notches. Try

swapping the bars around for the best fit. If the latter have been built up

with weld, the notches can be filed for an exact fit. Clearance should be no

more than necessary to allow free movement.

Replace

the screws using an impact driver and punch metal into the slots to lock them,

as they were before. Check finally that all gears can be engaged after fitting

the top temporarily.

Refitting the Gearbox to the Car

This

should be self-explanatory. If the clutch pedal has been removed, make sure the

cotter is refitted from the rear. Cotters of this type have a slope of some 10°

so fitting the cotter the wrong way round will mean the loss of some 20° of

clutch pedal movement - on a Seven this is an extravagance! Note this also when

replacing other cotters, particularly those in brake cam levers.

Lubricate

the clutch release bearing with castor oil. This tip was given to me by someone

who worked on Sevens during the Twenties and Thirties and seems to work well.

The bearing seems to last forever on a three-speed but the four-speed bearings

(that do not rotate continuously) are generally noisier.

If

you are fitting the gearbox, then the engine, there are two. points to watch:

First,

turn the engine and feel that each toggle lever is in its slot in the release

ring before bringing the engine and gearbox finally together.

Second,

fit the nuts on the bell housing before sliding the engine back into position,

as two of them are pretty well inaccessible afterwards.

The

job is easier if the gearbox top is fitted and the gearlever can then be used

to manoeuvre the box into position. Do not forget the oil!

(Adapted

from an article by Mike Phelan which appeared in the Pre War A7 Club Newsletter

for Oct 93 with many thanks)

le and continues to give good service, even when absolutely worn

out! Gearboxes rarely fail catastrophically. Nowadays, the supply of good

secondhand gearboxes is slowly diminishing, so we are having to rebuild them,

maybe using parts from several units.

le and continues to give good service, even when absolutely worn

out! Gearboxes rarely fail catastrophically. Nowadays, the supply of good

secondhand gearboxes is slowly diminishing, so we are having to rebuild them,

maybe using parts from several units. This provides a very necessary part of any selector mechanism, an

interlock to prevent more than one selector fork moving at a time. This, if it

were to happen would lock the box solidly and probably cause sever damage to

the car, and possibly its occupants!

This provides a very necessary part of any selector mechanism, an

interlock to prevent more than one selector fork moving at a time. This, if it

were to happen would lock the box solidly and probably cause sever damage to

the car, and possibly its occupants!