September 1978

DORSET AUSTIN SEVEN CLUB

EDITORIAL

When I look at the newsletters produced by the other clubs I am

very aware that ours is the smallest. However, our club also is the smallest

with a membership of forty plus compared with, say, Bristol with four hundred

plus. With more members you are kept supplied with materiel for publication,

more people give reports on different rallies and the sales, and wants are well

subscribed. Essentially, our newsletter provides news of club activities with

articles of interest as available and so it would be much appreciated if as

many members as possible could contribute something of interest to the

newsletter to save me scratching too hard!!

Down from the soapbox, do you think it would be a good idea if the

club purchased some essential trimming materials such as bonnet rubber and

glass channel, etc. in bulk so that our members could have it available when

necessary? The Solent have their own spares scheme; I

do not think we are big enough to do this; but we

could spend say, £30 or £40 on the more popular trimming materials.

On the motoring scene, Gary Munn has just returned from a trouble-free

800 mile tour of Cornwall - how do you get three people and all the camping

gear inside a 1930 box? He tells me at one stage they were three abreast in the

front - not much fun for the one in the middle!

John Dibben is the RAC timekeeper at Goodwood for two days of the

Chris Gould 10,000 mile attempt at the end of the month. I am sure we all wish

Chris the best of luck and hope the engine stays together this time. Some of us

had a good day at the Beaulieu Autojumble the other Sunday and even if we did

not find that elusive part we enjoyed looking for it. Yours truly bought a

Wedgewood Victorian toilet bowl which caused quite a laugh on the stall with

suitable comments written on it. Finally, when we were on holiday in Cornwall

recently we visited Daymer Bay near Padstow and when it was time to leave I

waved a blue Cortina in front of us which we followed out. We thought the

children in the back were enthusiastic about our windscreen until I realised

they had seen the DA7C badge - it was none other than John Stone from Wimborne

on holiday. This all proves that DA7C members are as intelligent in their

choice of holiday as their choice of car!

This Month’s Meeting - Thursday,

21st Sept. Meet at the Nags Head for a run to the Albany on the bridge at

Fordingbridge.

Next Months_Committee Meeting Thursday, Oct. 5th, Somerford Hotel.

Forthcoming Events: Stourpaine

Bushes Steam Rally, 22nd/23rd/24th Sept.

With the AGM coming up soon we thought you would like to be

reminded of our present committee.

Chairman - Derek Munn Secretary - Bernard

Cowley

Assistant Sec. - John Page Treasurer - Lawrence

Rideal

Events Secs. - Gary Munn & Peter Treliving

Newsletter Ed.- Phil Whitter

Committee Members.- Glyn Llewellyn & Mike Wragg

Technical Item Reproduced from the Midlands A7C for the benefit of fellow Austineers – hope they don’t mind!

Clutch Overhaul For Three

Speed Cars

Many Points Also Apply To Pre Borg And Beck Four

Speed

Before starting it is recommended that you get hold of Association

Magazine 1971 A and read the article contained therein, which is a copy of the

Austin

Seven Journal ("Confidential to dealers and service

depots"). This deals with a 1927 Austin Seven clutch overhaul. Obviously

they were dealing with relatively recent components in those days and since

then all the cars have had about fifty years of wear.

We all seem to manage to

take Austin Sevens apart with great ease, but sometimes come unstuck when

putting them back together again. Assuming you have first done a complete

rebuilding, no doubt a set of clutch linings have also been bought. Before

riveting them on, anxious to get the car going as quickly as possible, it pays

to have a look at the mechanical components that activate the clutch as these

all wear and can cause trouble. Look at your supply of engine crankcases and

see how many have been sawn and filed around the offside rear mounting to allow

further clutch pedal travel. Anyone guilty of this is a real Heathen. Problems

can be caused by the following - usually a combination of most of them.

1) Crankshaft not aligned centrally in the

crankcase, i.e. too far forwards.

2)

Crankshaft and/or flywheel taper

worn by repeated lapping.

3)

Worn thrust ring.

4)

Worn toggle levers.

5; Worn toggle lever pivot

pin.

6) Worn toggie posts.

7) Worn counter-bored holes in pressure plate.

8) Worn slots in starter ring plate.

9) Weak clutch springs.

10) Worn out linings - the easiest to cure.

Cures To Problems

1) This should never arise, of course, if the engine

was assembled properly. I once dismantled an engine with the crank nearly

1/8" forward.

2)

Not much you can do about this and it is also

not obvious to detect. Apart from metal

spraying or chroming the only thing to do is sort out compatible items. It is possible to bore the taper of a 1 1/S"

flywheel out to suit a worn 1 5/16" crank. It is then necessary to shrink

a ring onto the front of the flywheel

boss to suit the bore of the rear main bearing oil retaining helix: not very

practical, but possible to save an otherwise particularly good or rare

crankshaft.

3) Worn thrust rings are very common. They always wear where the

toggle levers bear. The usual cure is to cut three more slots equally spaced

around the ring. I prefer to weld the hollows up and machine or file them flat

again. This always seem more of a repair, whereas cutting more slots is a bodge. If the thrust

ring does not fall out you will find it levers out of the thrust bearing quite

easily.

4)  Worn toggle levers are the real problem. I have got various different

sorts, some of which are obviously home-made.

The originals I am using are a very hard forging, but even they were

worn on the fulcrum point. To overcome this I ground away the old points and

filed half-round seatings which it was then possible to braze hardened steel

3/16" diameter slugs into. The filing was done with all the levers clamped

together to keep them even. The hole on which each lever pivots is seldom badly

worn.

Worn toggle levers are the real problem. I have got various different

sorts, some of which are obviously home-made.

The originals I am using are a very hard forging, but even they were

worn on the fulcrum point. To overcome this I ground away the old points and

filed half-round seatings which it was then possible to braze hardened steel

3/16" diameter slugs into. The filing was done with all the levers clamped

together to keep them even. The hole on which each lever pivots is seldom badly

worn.

5) Worn toggle lever Pivot pins can easily be replaced with new pins

made from hardened silver steel or case-hardened mild steel. It is not really

necessary to peen the end of the pins over to keep them in the toggle posts as

the main starter ring plate prevents them dropping out.

6) Worn toggle posts are a problem. If you have a hoard of spares or

can scrounge good parts, all well and good. The ideal answer is to make new

ones, but unless you have a small lathe or attend evening classes with

machinery available there is no real answer.

7) These holes do wear together with the toggle parts. It is possible

to deepen the counter bores to clean up the seatings and then fit three washers

which you will have to make to space the toggle parts back to their true

position.

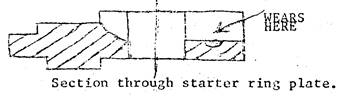

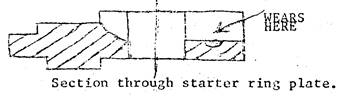

8)  Worn toggle slots in starter

ring plate. The fulcrum point of the toggle levers bears in a slot machined on

the starter ring plate. Consequently, this slot wears at the point of contact. These

are best restored by welding carefully and filing the base of the slot flat

again, or preferably mill them out. If you can't weld, drill and tap a hole at

the point of wear, tap it 1/4" BSF and "Loctite" a short length

of high tensile threaded stud, protruding into the slot slightly. When set,

file flush as before. Four speed cars

which have the "mousetrap" springs are more easily rectified. Cut off

three pieces of 5/32" silver steel just long enough to fit across the

slots and harden them, (The plain part of a broken 5/32" drill is ideal.

Grind to length!) Assemble the flywheel assembly, locate the 5/32" steel

slugs between the toggle posts and toggle lever fulcrum. Trap them there with

the levers and hold the levers down with the mousetrap springs.

Worn toggle slots in starter

ring plate. The fulcrum point of the toggle levers bears in a slot machined on

the starter ring plate. Consequently, this slot wears at the point of contact. These

are best restored by welding carefully and filing the base of the slot flat

again, or preferably mill them out. If you can't weld, drill and tap a hole at

the point of wear, tap it 1/4" BSF and "Loctite" a short length

of high tensile threaded stud, protruding into the slot slightly. When set,

file flush as before. Four speed cars

which have the "mousetrap" springs are more easily rectified. Cut off

three pieces of 5/32" silver steel just long enough to fit across the

slots and harden them, (The plain part of a broken 5/32" drill is ideal.

Grind to length!) Assemble the flywheel assembly, locate the 5/32" steel

slugs between the toggle posts and toggle lever fulcrum. Trap them there with

the levers and hold the levers down with the mousetrap springs.

9) It is recommended by the experts that you fit new springs as a

matter of course. What I usually do is sort through a few sets of springs and

put the longest ones in! You should, of course, buy new ones. It is possible to

fit a second set of springs inside the originals for the go-faster get-aways.

10) Replace old linings with new from John Platts

of Bristol (See Assoc. Mag) If riveting yourself ensure that the rivets are

tight. John Platt and other suppliers will usually fit linings for you. John

charges £1, Make sure that the toggle levers and posts are in situ in the

pressure plate before riveting on lining.

.

FINAL NOTES

Lubricate all moving parts with a smear of 'Copaslip’.

The distance of the end bearing faces of the de-clutching toggle

levers from

the clutch plate face should be tested. When they are about to act

against the clutch springs this distance should be 1" to 1 3/16", each

lever being the same distance from the clutch plate face. If the levers require

re-setting it is possible to

adjust them by bending them with the jaws of an adjustable spanner. After

refitting the gearbox to the engine check that the clutch plate is free when

the clutch is out, by turning the flywheel by a bar in one of the holes around

its rim, The motion shaft through the gearbox should not turn whilst doing this,

If the motion shaft does move it means that the clutch is not fully disengaged.

This condition is due to bad adjustment of the declutching toggle levers which

should be readjusted so that the clutch can be freed entirely.•

It is far easier to understand all the foregoing when actually

faced with the items. I hope that this will be of some help to anybody who has

been suffering with clutch problems.

Worn toggle levers are the real problem. I have got various different

sorts, some of which are obviously home-made.

The originals I am using are a very hard forging, but even they were

worn on the fulcrum point. To overcome this I ground away the old points and

filed half-round seatings which it was then possible to braze hardened steel

3/16" diameter slugs into. The filing was done with all the levers clamped

together to keep them even. The hole on which each lever pivots is seldom badly

worn.

Worn toggle levers are the real problem. I have got various different

sorts, some of which are obviously home-made.

The originals I am using are a very hard forging, but even they were

worn on the fulcrum point. To overcome this I ground away the old points and

filed half-round seatings which it was then possible to braze hardened steel

3/16" diameter slugs into. The filing was done with all the levers clamped

together to keep them even. The hole on which each lever pivots is seldom badly

worn.