DORSET AUSTIN SEVEN CLUB December

1976

SECRETARIAL December always seems a very quiet month on the A7

scene - everyone getting on with their restoration, or dare I call it

resurrections. Peter Treliving has just torn apart his Ruby and Phil Whitter is

busy building a garage to store and rebuild his Ruby. Chris Smith's Ruby seems

well on the way to being ready for the road and likewise Gary Munn's 30/31 Box.

Nice to see that Geoff Kingsland’s Ruby has now overcome its oil leaks. He was

telling me that the rear main bearing carrier did not have a drain hole and

subsequently the oil was running straight out into the clutch housing instead

of back to the sump!

I was very surprised at the turn out at the last

meeting and also how many Sevens there were in the car park - considering that

there was Miss World on the box. First on the agenda was to choose the club

badge. Type B in last month’s newsletter was chosen by a majority decision

after a lot of discussion about the merits of the other 14 badges on show - a

very good effort by everyone concerned. A copy was then shown around of the

Austin Seven Journal, which I can supply to members on club nights for the

princely sum of 10p when available.

Next came the highlight of the evening, a showing of slides of Beaulieu,North Devon runs, Longbridge rally, a few buses

and some of Singer rallies from John (1924; Singer) Bramwell.

NEXT CLUB NIGHT December 16th We have devised what is called a

Tabletop Concours - that is any part belonging to, or associated with, a car in

immaculate order, or even a model of a car which you have made, will be judged.

There will be two teams, each judging the others items. A prize will be given

for the best item of the evening - only one entry each please.

This month’s newsletter consists of "How to set

up a front axle", courtesy of the 750 Bulletin 1955 and further episodes

from the Austin Seven Service Bulletin. This month - how to remove a Ruby

gearbox.

SALES AND WANTS

Wanted Rear side window frames and

catches for '35 Ruby and shock-absorber star spring. Chris Smith Ferndown

874205

Wanted Very Urgent - 30/31

Headlights - a pair. Gary Munn Ferndown

891473

Wanted 31/32 Gearlever for 3-speed

box. Richard Cowell Sturminster

Newton 72573

Wanted Nearside front wing and

door for '35 Ruby. M.A.Field, 62 Weldon Avenue, Bear

Cross.

Wanted Clutch thrust bearing for

Ruby. Dave Rogers, c/o Herbert Hospital, Alumhurst

Road, Westbourne.

Wanted Pair front seat squabs and

radiator grill side-plates for 1936 Ruby. Phil Whitter.

A Ruby might possibly be for sale for a reasonable price, near

Ringwood. See Phil for details.

Please inform Phil Whitter on clubnight or at 89 York Road,

Broadstone Tel. Broadstone 04857, re. your sales and wants.

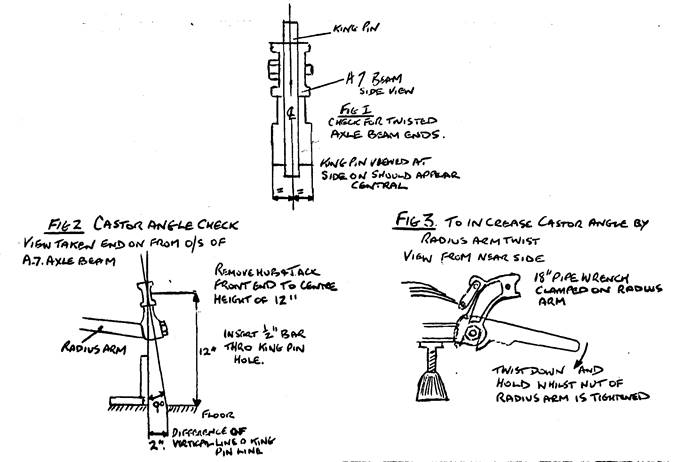

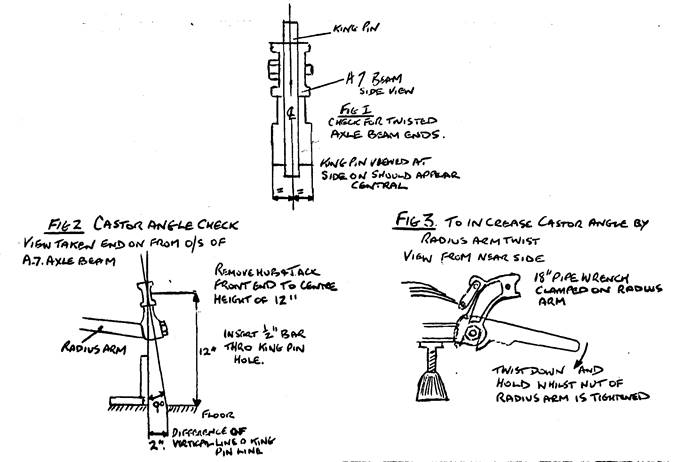

FRONT END ATTENTION by K. A. Bowden

Good steering depends firstly on a sound axle beam

correctly aligned. In the case of the A7 beam, check that the king pin retaining

ends are not twisted (See Fig. 1).

The system should be made self-centering, back-lash

in the steering box or joints is not really important though rather

undesirable. With ordinary standard shock absorbers and a level road you should

be able to release the wheel and still keep straight ahead. Ninety percent of

lack of stability is due to having insufficient castor rake on the axle beam.

Have a look at the front forks of a motor cycle or

bicycle sideways on. Fig. 2 shows the A7 beam viewed side-on from the offside with

the stub axle removed. The rake should be nine degrees positive. (It never is

as standard). If the chassis is level in normal road trim this is easily

obtained by loosening off the radius arm nuts, twisting each arm in turn, and

whilst so twisted lock the nut up tight (Fig. 3) If the chassis is high at the

rear, i.e. cambered springs, lower the radius arm fixing ball joint on a piece

of 1/4 “ plate below the level of the first cross member. A simple means of

checking is shown in Fig. 2 taken on a level floor. Toe-in and toe-out only

wear the tyres. Generally speaking the radius arms should be horizontal.

Unless the rear springs are heavily cambered, this-treatment gets -rid of

oversteer as well.

MARCH, 1935 56

AUSTIN SEVEN GEARBOX REMOVAL

AS all our Dealers may not be aware that the

gearbox of the latest type Austin Seven can readily be withdrawn from inside

the car, thereby effecting a considerable saving in time and cost, we herewith

describe the job fully, giving the correct sequence of operations for which the

average time taken is 5 hours, which includes for replacing.

MARCH, 1935 57

Austin Seven — Gearbox Removal

—(contd.)

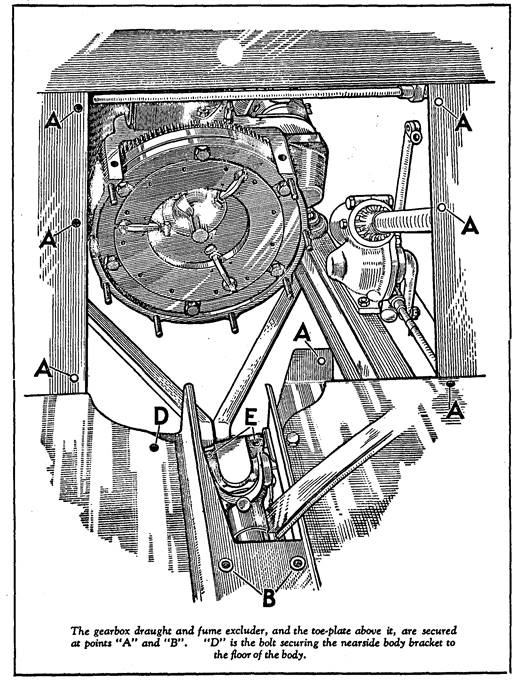

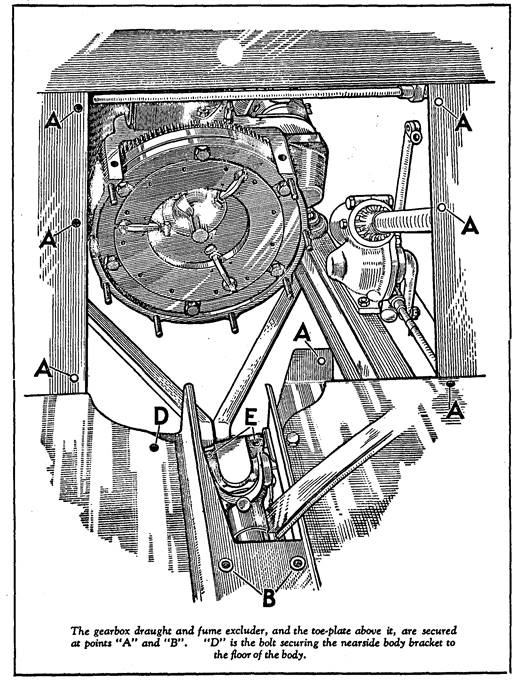

First take out both the

front seat cushions and the front rubber floor coverings. Then remove the eight

nuts and bolts at "A" in the accompanying illustrations and the two

setscrews at "B" with their lock-washers that together secure the

gearbox fume excluder, and the toe-plate above it, to the metal floor.

Working from underneath the car, fully slacken off the hand-brake

lever adjustment and disconnect the speedometer coupling from the gearbox.

Returning to the interior of the car, release the metal gearbox shield from the

rubber seal round the base of the gear lever and remove the shield by pulling it

up and off the gear and hand-brake levers after pulling the latter right back.

The rubber seal can be left on the base of the gear lever.

Lift the offside of the bonnet and slacken the nuts and bolts

securing the brake- and clutch- pedal stalks in the split ends of the levers.

Returning to the front compartment, withdraw the pedal stalks through the toe

plate, and remove this plate.

Lift the offside of the bonnet and slacken the nuts and bolts

securing the brake- and clutch- pedal stalks in the split ends of the levers.

Returning to the front compartment, withdraw the pedal stalks through the toe

plate, and remove this plate.

Unlike the offside transmission tunnel body-bracket (which is

riveted) the body-bracket on the nearside is bolted to the frame to allow it to

be easily removed, which should now be done by undoing its three securing bolts to the frame and a further

bolt passing through the floor (see the illustration herewith). The fibre

packing piece shown in the illustration must be carefully retained and replaced

when refitting the body bracket.

Bend back the lock-washer tags of the four nuts and bolts

"E" (see main illustration) securing the front propeller shaft joint

to the third motion shaft, unscrew the nuts, remove the four bolts, draw the

joint back on its splines and allow the propeller shaft to rest on the

hand-brake cross shaft.

Remove the eight nuts and washers from the studs securing the

gearbox to the flywheel housing, and the two setscrews retaining the flywheel

pit cover. It will then be possible to draw the gearbox off the studs and the

splined clutch plate centre and lift it out of the car from the nearside.

Replacing the gearbox is simply a reversal of the operations

described above.

In our next issue we hope to deal with relining the latest Seven

clutch for which several special tools are available.