April 1977

DORSET

AUSTIN SEVEN CLUB

SECRETARIAL April usually seems the

month to get the '7' out of the garage and dust the cobwebs off - apart, of

course, from the few hardy types that motor during the winter. It is also the

start of our monthly evening runs.

There has been a lot of discussion in recent

months about the running of an Austin 7 club. To avoid certain difficulties

that have arisen within other clubs we have decided not to over-publicise ours.

We believe that too many members may endanger the informality that exists. By

the way, we now have 33 members and welcome to J. Harris o Salisbury - one of

his cars, a 1923 A7, has been on show at Beaulieu.

By the time you have read this the Daffodil

Run will have come and gone and I hope all those that entered enjoyed

themselves.

I have received further details of the 10,000

mile Record Attempt by Chris Gould and the Pre-War A7 Club. Eight drivers

working in three hour shifts had completed 4,147 miles, most of it at an

average speed of over 50 mph, before the crankcase bolts sheared leaving the

block floating about. However, subject to confirmation they have broken the

1,000 km and 5,000 km Records for Class 4, Category 4, Group 1 cars.

Congratulations.

This month I am starting a "Spotlight

On" section, so if I ask a few awkward questions, watch out

Spotlight On PETER TRELIVING

Peter has been interested in 7's for about

eighteen months. Originally he saw an advert in the Echo for a 1930 Chummy in

bits - without a body and started renovating. After realising that he could not

enter any runs, etc. for many a year he started looking for another '7'. At

last he found the right one - a '36 Ruby, which he bought just before Longleat

Rally last year - and has now just finished renovating it in a record time of

four months. It certainly has been a wonderful effort.

Peter is an electronics engineer by profession and lives with his

wife, Judy, and two children at Merley.

FORTHCOMING EVENTS

1st May - May Day Run. Starting point Wimmborne Square 10.45 are for 11.15 a.m

start. Lunchtime stop at a suitable public house and ending at the Blue Pool.

Details subject to revision on the day. If you are coming, please try to let me

know beforehand. Please try to support it as it is our first official run.

28th/29th May - Bristol A7 Club has decided to go ahead with the

North Devon Run.

4th/7th June - Bristol A7 Club Scrumpy Run

to Dorset.

19th June -

Essex A7 Club Motoring Extravaganza at Southend Airport (I have some entry forms).

25th June -

Ferndown Jubilee Celebration Rally & Concours. Free

entry, free teas. I hope to have some entry forms at our next

meeting.

NEXT CLUBNIGHT - 21st April, Nags Head, Ringwood. A short run

to the Red Shoot Inn, Linwood, leaving at approx. 8.45 pm.

FOR SALE 1936

crankcase - Ruby valve cover and studs

Ruby chassis - two 19"

wheels (chrome centre; four 17" large chrome centre wheels - clutch plate

- 14mm plug cylinder head, '37 type one pair Ruby bumper hangers; fuel tank one;

n/s early Ruby door - a pair of Ford Model Y headlights - rear bumper for

Morris 8. Richard Cowell, Sturminster Newton 72513 (work)

FOR SALE Two head gasket sets '36-'39 new. £3 each. Phil Whitter, Broadstone 094857

WANTED 6

volt horn - vacuum wiper - updraught 22FZB carb. Clutch thrust and pressure plate for '31/32 box. Richard Cowell, as above.

WANTED Solid

centre wheels - early starter housing and drive - clutch thrust - pair of small Lucas

headlights - front axle for 1928/29 saloon. Phil Whitter, as above.

JUNE, 1935 114

JUNE, 1935 114

Austin

Seven—Relining the Clutch—(contd.)

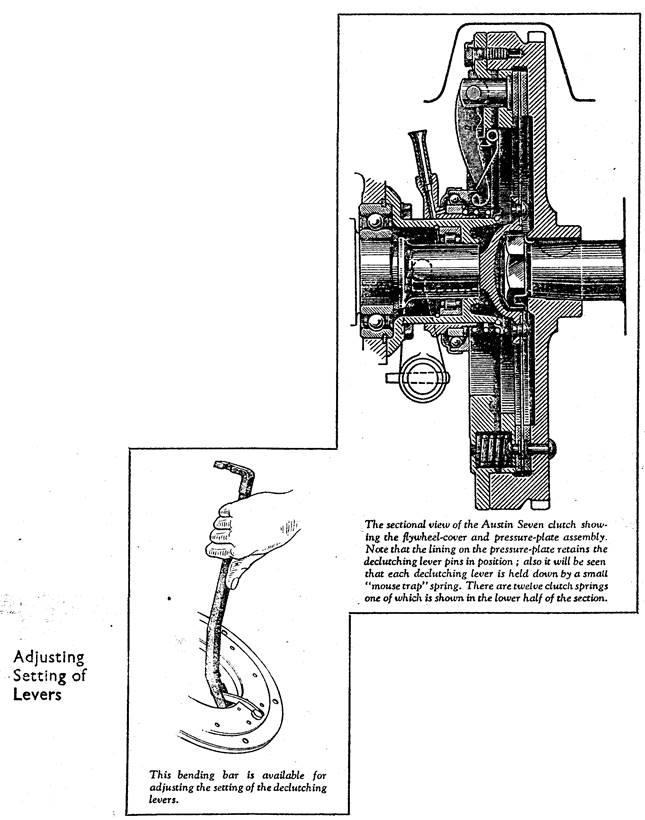

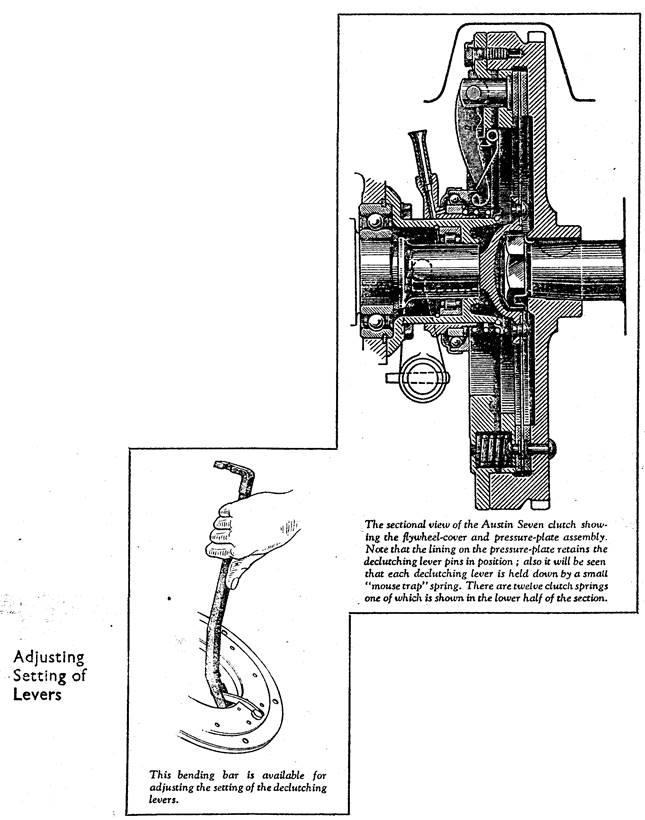

For reassembling the clutch, first place the pressure-plate,

lining downwards, on the jig, replace the twelve clutch springs in their

sockets in the upper surface of the plate and swing the declutching levers up

into a vertical position to enable the flywheel cover to be threaded over

them. The jig can then be used to compress the whole assembly so that the three

levers swing towards the centre of the clutch.

To ensure a sweet clutch action without vibration, each declutching

lever must have its correct working clearance. This can be tested at this

stage, while the assembly is in the jig, with the special gauging table which

mounts under the jig by the pin and bayonet socket fixing as shown. Note that

the pins must be right home in their slots for the locating faces on the ton,

of the table to be tight against the bottom face of the jig; both surfaces must

be quite clean. The gauge block and feeler can then be used as shown to check

the position of the working face of each declutching lever, which can be set if

necessary by the bending , bar depicted on this page.

Having verified the setting of the levers

their springs can be refitted, using the special pliers as shown in the illustration. The declutching lever

retaining ring, previously described, should be in position on the levers

before the assembly is removed from the jig.

The flywheel can be replaced on its keyed

taper on the end of the crankshaft and secured by its nut and lock-washer,

being again prevented from turning by placing a bolt in its periphery.

Next

rest the clutch plate against the flywheel lining and offer up the assembled

flywheel cover for each of its six setscrews to be refitted and partly screwed

up. Then remove the retaining ring from the declutching levers and centre the

clutch plate. A special centring bar is available for this purpose, the two

outer holes of which fu over two opposite studs in

the flywheel housing. When the splined clutch plate centre is located in the

middle hole in the plate, the six setscrews can be tightened home.

Next

rest the clutch plate against the flywheel lining and offer up the assembled

flywheel cover for each of its six setscrews to be refitted and partly screwed

up. Then remove the retaining ring from the declutching levers and centre the

clutch plate. A special centring bar is available for this purpose, the two

outer holes of which fu over two opposite studs in

the flywheel housing. When the splined clutch plate centre is located in the

middle hole in the plate, the six setscrews can be tightened home.

Supplementing the information given in the last issue on removing and re-

placing the gearbox, it is advisable to

slacken off the clutch pedal adjustment, as this will facilitate manoeuvring

the clutch pedal lever past the steering box. It will be noticed that the

clutch plate centre has one spline missing for location purposes and refitting

the gearbox is rendered easier if this gap in the spline is on top centre. Therefore,

engage top gear and turn the third motion shaft flange until that portion of

the first motion shaft that corresponds to the missing spline on the clutch-plate

centre is also on top centre. Next mark the third motion shaft flange and the

rear of the gearbox, so that this position can be reverted to when the gearbox

is offered into position, which is best done through the nearside door. With

the gearbox refitted the remainder of the reassembling process is a reversal of

the dismantling procedure outlined in the article appearing in the March issue

of The Austin Service Journal. It

will be necessary, of course, to reset the clutch pedal to give the play

necessary for the

efficient functioning of the clutch.

The average time taken for the above is

approximately 7¾ hours.

The following is a list of reference numbers

of the assembly jig and other tools mentioned in this article. We advise their

use, as makeshift tools tend to damage the parts to which they are applied. It

is, of course, possible to compress the clutch in a vice, for the removal of

the declutching lever springs, shifting it round as necessary to deal with each

lever, but this involves the risk of cracking the pressure plate lining, which has to withstand the pressure on

the declutching Lever pins.